Light guide plate and image display device

A light guide plate and grating technology, applied in optics, light guides, optical components, etc., can solve problems such as narrow viewing angles, and achieve the effect of improving brightness and visual recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

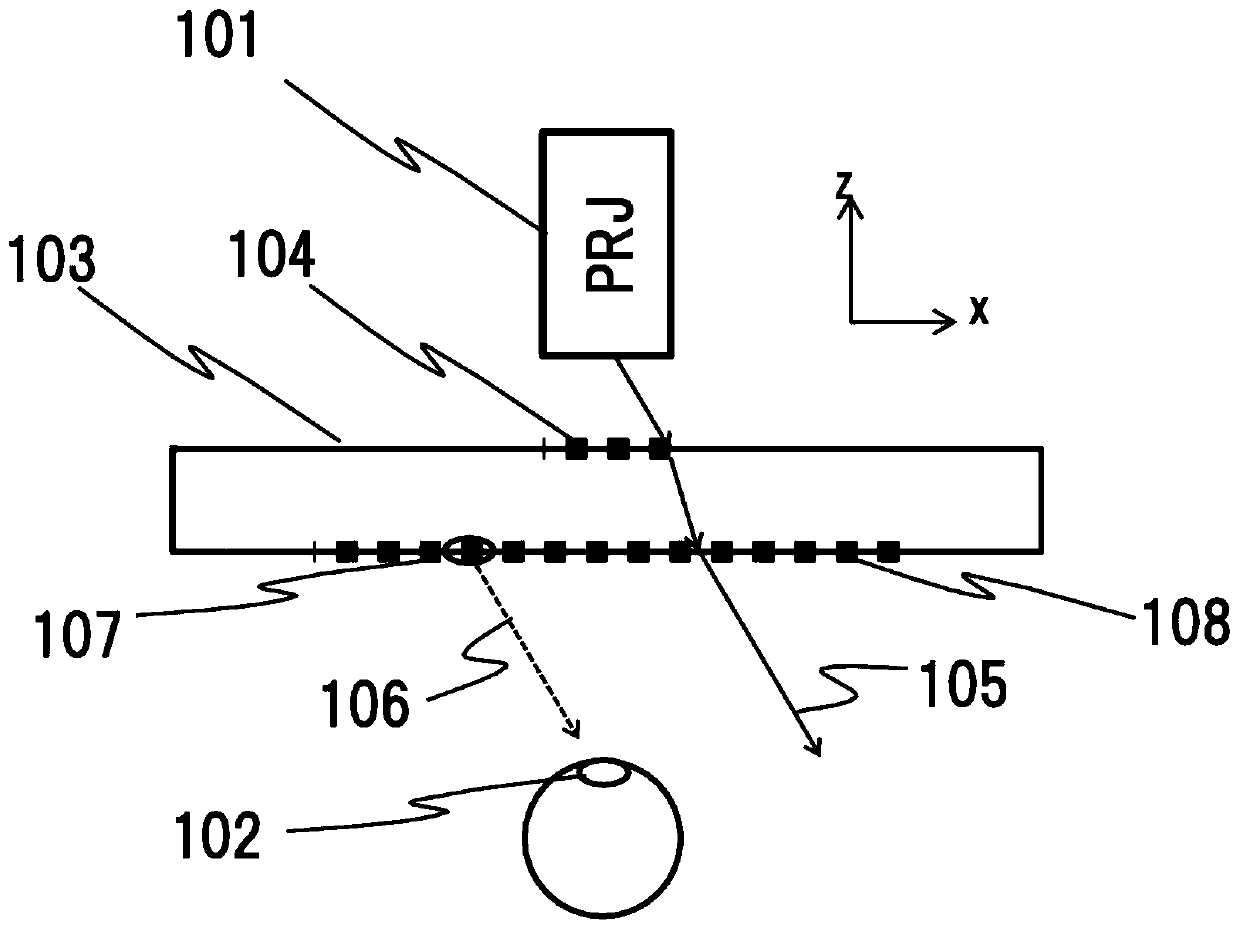

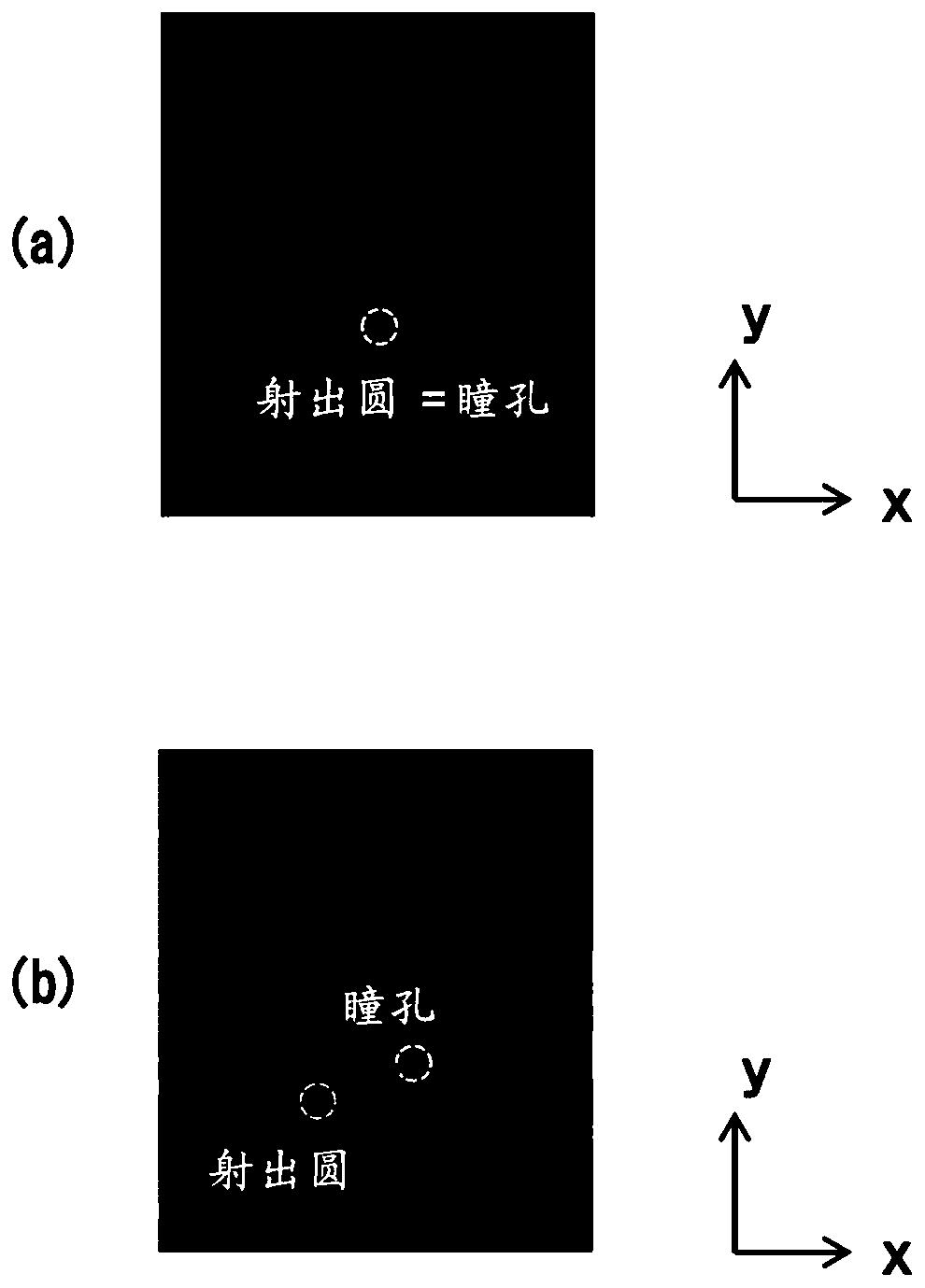

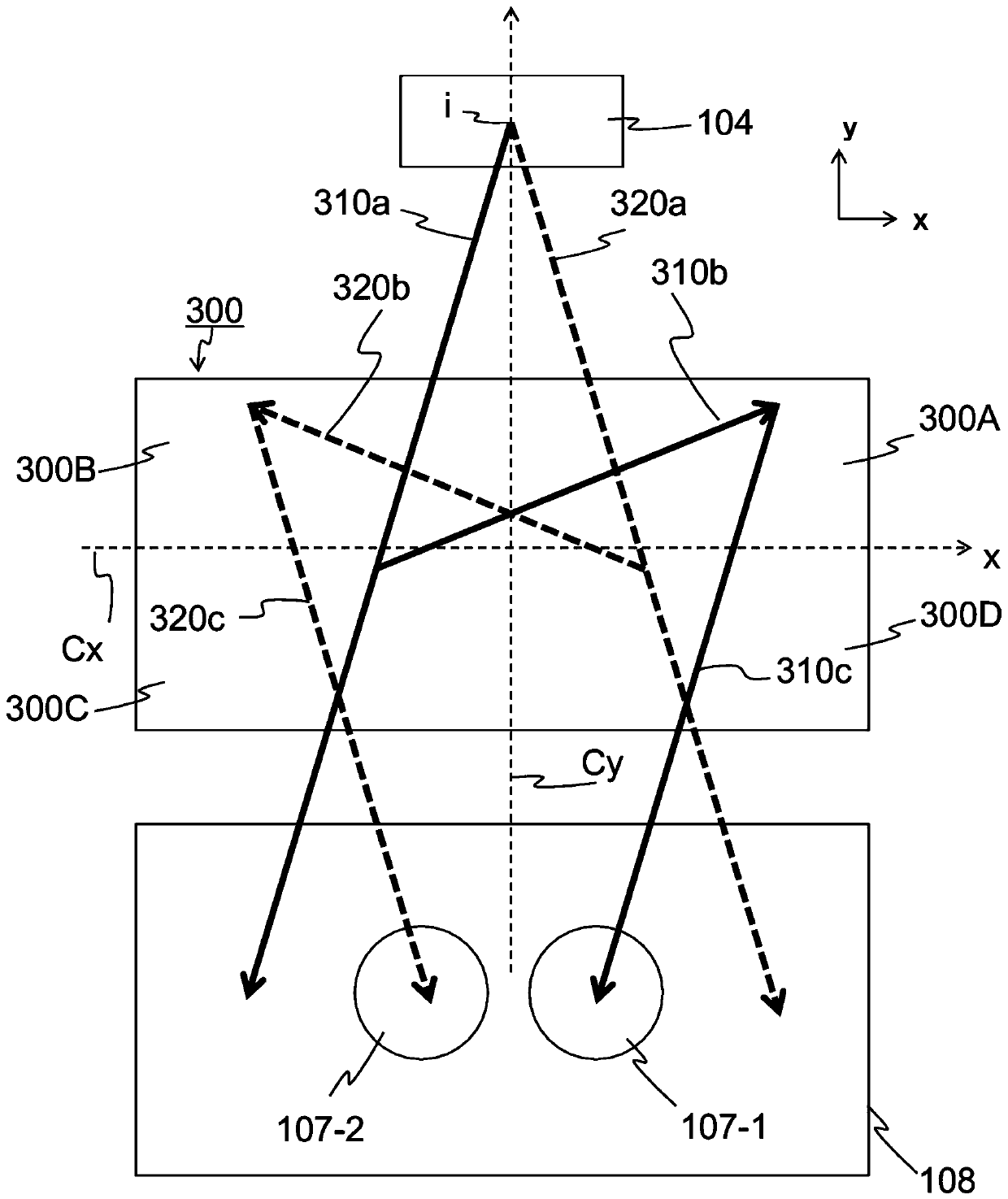

[0143] Figure 8 The structure of the image display element of this embodiment is shown. Hereinafter, the present invention will be described using the angle θ formed by the period P of the surface unevenness pattern and the X-axis as a parameter for determining the wave vector of the diffraction grating. In the figure, an incident diffraction grating 104 (period P, angle θi=0), an output diffraction grating 108 (period P, angle θo) and an intermediate diffraction grating 300 (period Pm, angle θm) are formed on the light guide plate 103 . The incident diffraction grating 104 is composed of a linear grating elongated in the x direction, and the period of the pattern is P. The periodic direction of the pattern of the incident diffraction grating 104 is the y direction. The output diffraction grating 108 is a linear grating whose pattern period is also P, and the angle formed between each grating and the x-axis is θo. In the case of the light guide plate described in Patent Do...

Embodiment 2

[0168] Figure 15 It is a schematic diagram showing the whole process of forming the light guide plate of the present example utilizing the mass production process of the optical disk, and is a diagram schematically showing the manufacturing process of the image display element of the example. First, if Figure 15 As in step 1 shown in (a), prepare the master pattern 1501 of the incident diffraction grating and intermediate diffraction grating and the master pattern 1502 of the outgoing diffraction grating by EB (electron beam) drawing method or the like. The master mold 1502 for emitting the diffraction grating was transferred to a Ni stamper in a manner suitable for the injection molding process, and used.

[0169] Then, if Figure 15 As in step 2 shown in (b), the substrate 1503 on which the emission diffraction grating 108 is formed on the surface is produced by injection molding using a plastic material using the master mold 1502 for the emission diffraction grating. A...

Embodiment 3

[0182] Figure 17 It is a schematic diagram showing the structure of the image display device 1700 of this embodiment. The light with image information emitted from the projector 101 reaches the pupil 102 of the user through the functions of the light guide plates 103R, 103G, and 103B of B, G, and R, thereby realizing augmented reality. The light guide plates 103R, 103G, and 103B of B, G, and R are Figure 15 Optical device 1506 is shown, forming a diffraction grating whose pitch and depth are optimized for each color.

[0183] In the drawing, an image display device 1700 is composed of an optical device 1506 , a projector 101 as an image forming unit, and a display image control unit (not shown). Here, the optical device 1506 integrates R, G, and B light guide plates 103R, 103G, and 103B for color display. In addition, as an image forming unit, for example, an image forming device composed of a reflective or transmissive spatial light modulator, a light source, and a lens,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com