Interleaved totem-pole bridgeless PFC phase control method

A phase control and totem pole technology, applied in the direction of high-efficiency power electronic conversion, output power conversion devices, electrical components, etc., can solve the problems of inability to guarantee, low switching loss, complexity, etc., to achieve small switching loss, reduced switching loss, The effect of increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described below in conjunction with accompanying drawing and embodiment:

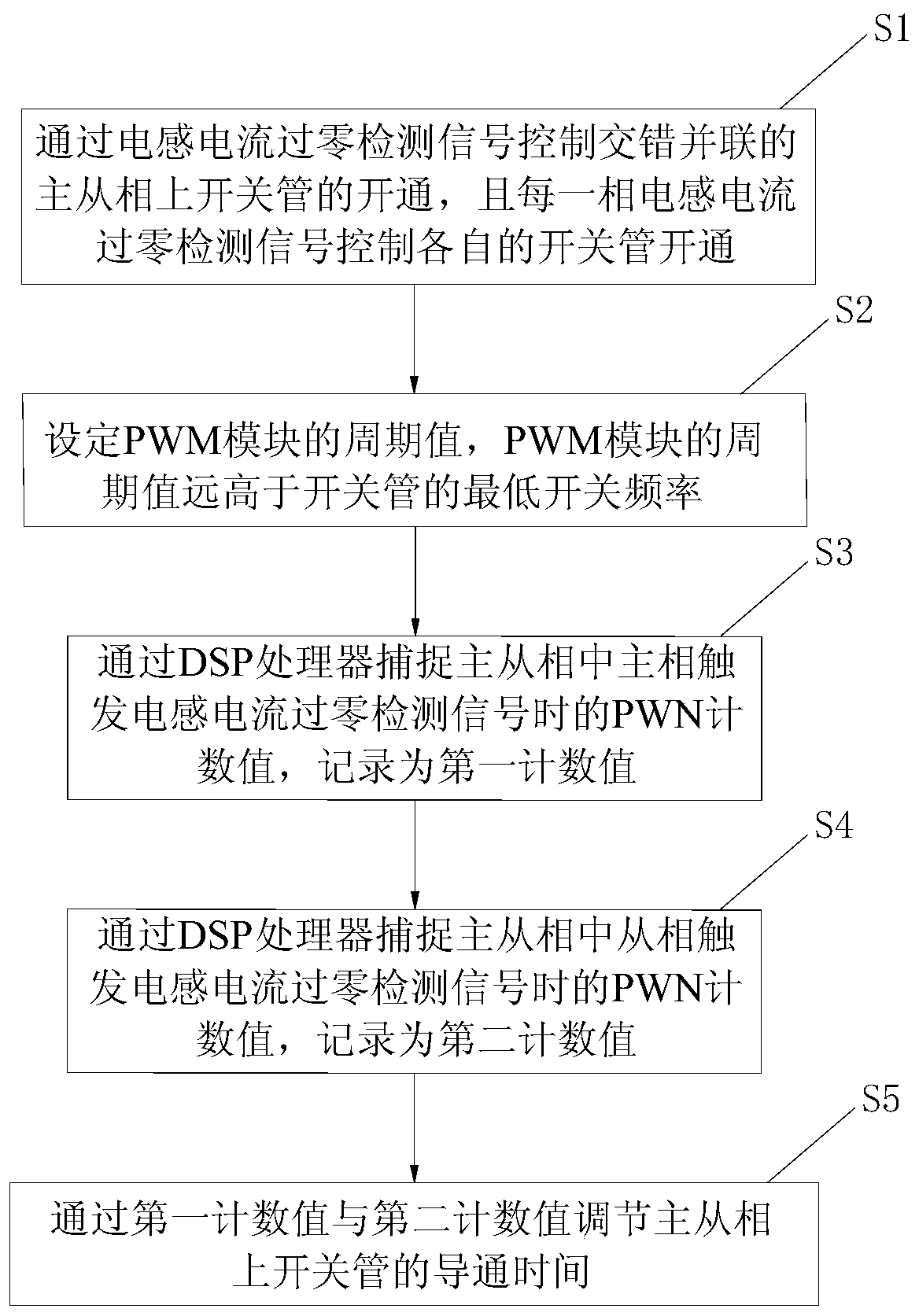

[0034] Such as figure 1 As shown, an embodiment of the present invention provides a phase control method for an interleaved parallel totem pole bridgeless PFC, which includes the following steps:

[0035] Step S1: Control the turn-on of the switching tubes on the interleaved parallel master and slave phases through the inductor current zero-crossing detection signal, and control the respective switching tubes to be turned on by the inductor current zero-crossing detection signal of each phase.

[0036] Step S2: Set the period value of the PWM module, the period value of the PWM module is higher than the minimum switching frequency of the switching tube. Generally, the period value of the PWM module is much higher than the minimum switching frequency of the switching tube. When the switching frequency of the switching tube is higher than the period value of the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com