Composite aroma Xiaoqu liquor

A technology of Xiaoqu liquor and compound aroma, applied in the field of food processing, can solve the problems of short sweetening time, heavy bitterness, lack of aroma, etc., to improve taste and odor evaluation, reduce bitter aftertaste, and enhance the aroma of base wine. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1: The brewing of compound-flavor Xiaoqu liquor sample 1

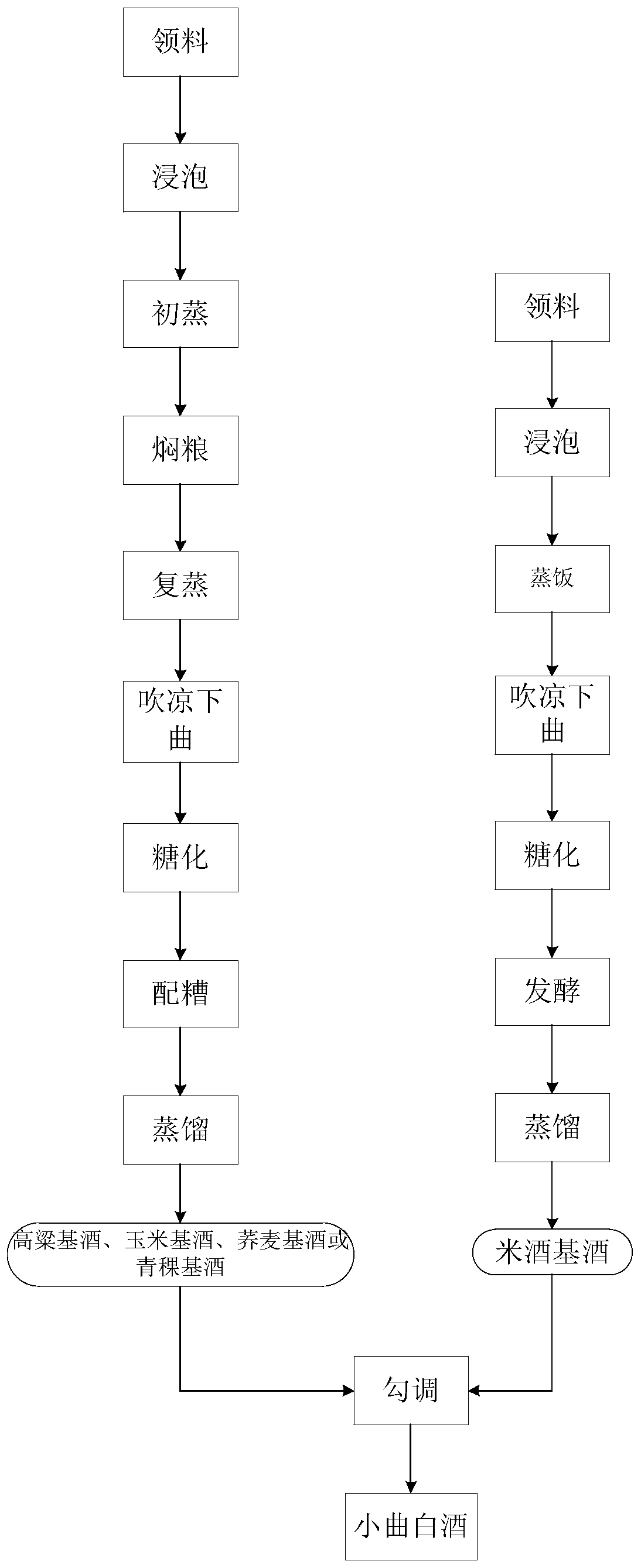

[0088] see figure 1 , the compound flavor Xiaoqu liquor provided by this application, according to figure 1 Shown process brewing obtains, and the brewing process used in remaining embodiment is with reference to figure 1 .

[0089] Wherein the rice wine is brewed according to the following steps:

[0090] Picking material: rice and purple glutinous rice are mixed by 1 weight part of rice 4 weight parts and Mojiang production purple glutinous rice (all are this in the following each embodiment);

[0091] Soaking: Mix rice and purple glutinous rice and soak in tap water for 2 hours;

[0092] Rice steaming: release the soaking water, and steam the rice with a continuous rice steamer to obtain mixed rice that is soft and lifeless;

[0093] Blowing and cooling the next koji: Cool the mixed rice to 32°C, and add koji to it. The koji is about adding Angel sweet koji and mixed koji to the mixed rice at ...

Embodiment 2

[0108] Embodiment 2: the brewing of compound flavor Xiaoqu liquor sample 2

[0109] Wherein the processing method of rice wine:

[0110] Picking: rice and purple glutinous rice are mixed by 10 parts by weight of rice and 1 part by weight of purple rice;

[0111] Soaking: Mix rice and purple glutinous rice and soak in tap water for 2 hours;

[0112] Rice steaming: release the soaking water, and steam the rice with a continuous rice steamer to obtain mixed rice that is soft and lifeless;

[0113] Cool down the koji, cool the mixed rice to 30°C, add koji to it, add Angel sweet koji and mixed koji to the mixed rice at a weight ratio of 4:1.5, and the koji accounts for 6‰ of the total weight of the raw materials of rice and purple glutinous rice; The mixed distiller's koji is composed of Rhizopus niger and Aroma-producing yeast in a mass ratio of 3:3.

[0114] Saccharification in the tank, the mixed rice added with koji is saccharified in the tank at 25°C for 18 hours, and the t...

Embodiment 3

[0128] Embodiment 3: the brewing of compound flavor Xiaoqu liquor sample 3

[0129] Wherein the rice wine is brewed according to the following steps:

[0130] Picking: rice and purple glutinous rice are mixed by 7 parts by weight of rice and 1 part by weight of purple rice;

[0131] Soaking: Soak the mixture of rice and purple glutinous rice in water for 1.5 hours;

[0132] Steamed rice: Take out the soaked mixture and steam it in steam for 1.5 hours, until the rice is soft and has no heart, and mixed rice is obtained;

[0133] Cool the next koji: Cool the mixed rice to 35°C, add distiller’s koji to it, add Angel’s fermented koji and mixed koji to the mixed rice at a weight ratio of 4:2, the quality of distiller’s koji accounts for 5.5‰ of the total weight of rice and purple rice raw materials The mixed distiller's yeast is composed of Rhizopus niger and Aroma yeast in a mass ratio of 2:1.

[0134] Saccharification in the tank: the mixed rice added with koji is saccharified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com