Energy-saving heating device and method of use

A technology of heating device and economizer, applied in the field of HVAC, can solve the problems of low utilization rate of condensed water, difficult hydraulic balance adjustment, high maintenance cost and operating cost, and achieves avoiding slow temperature rise, reasonable structure, and reduced maintenance. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

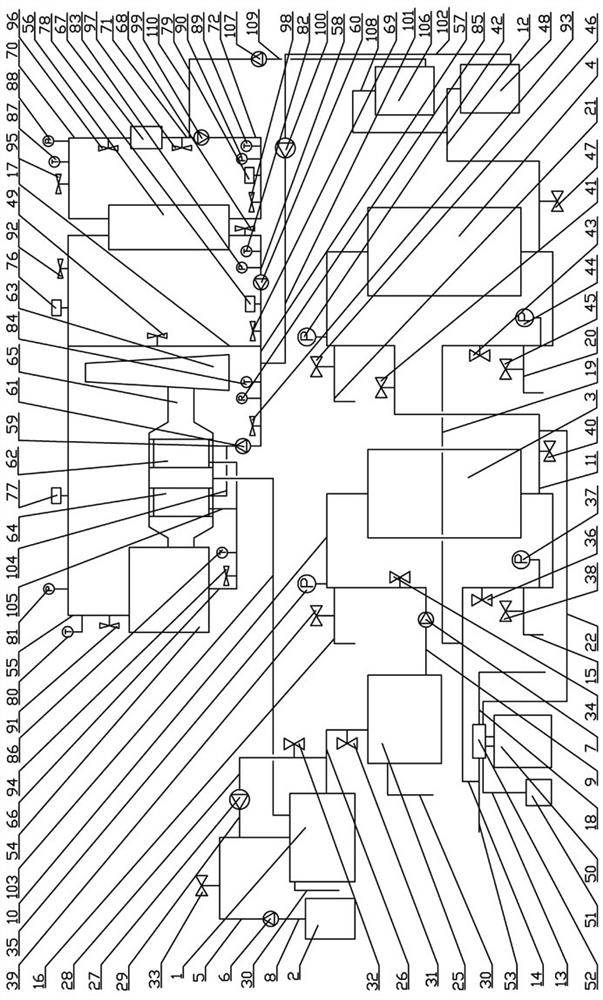

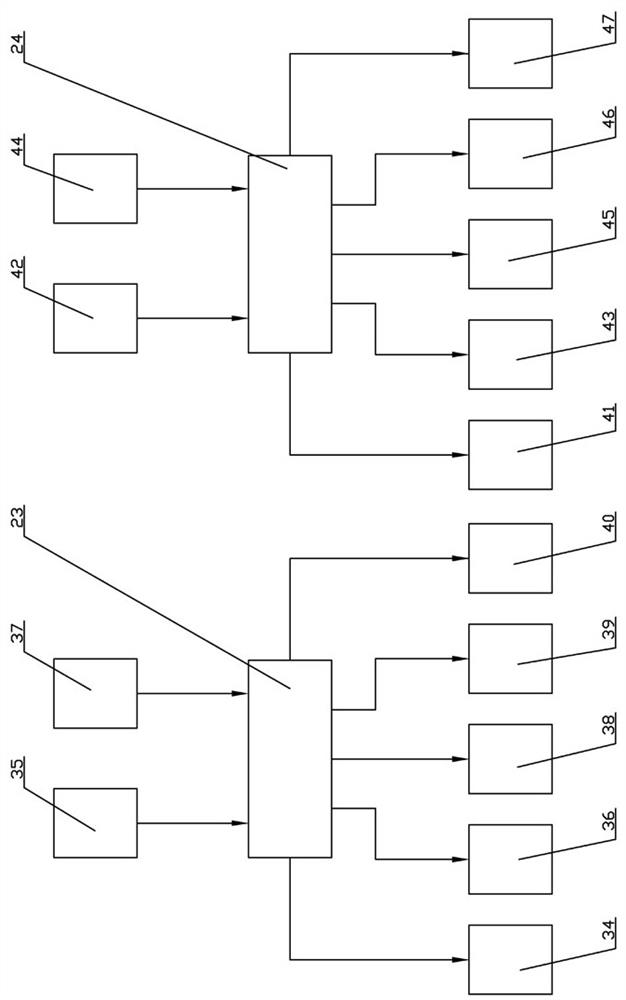

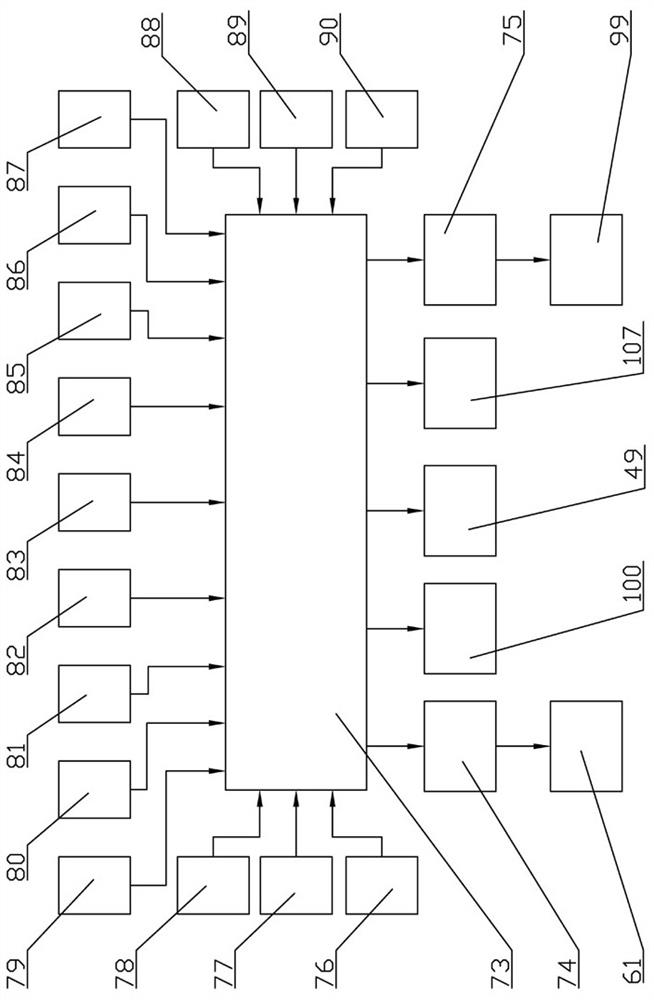

[0030] Embodiment one: as attached figure 1 , 2 , 3, the energy-saving heating device includes a boiler 54, a primary economizer 64, a secondary economizer 62, a chimney 63, a condenser 65, a primary side primary water pump 60, a primary side secondary water pump 61, and a condensed water tank 1. The first network water tank 48, the second network water tank 106 and the primary side water supply pump 100. The condenser 65 is a hollow tube with a thick middle and thin sides and is horizontally arranged. The exhaust port of the boiler 54 and the air inlet of the chimney 63 are condensed The condensers 65 are fixedly connected together, and the inner side of the middle part of the condenser 65 is fixedly installed with a primary economizer 64, the air inlet of the primary economizer 64 corresponds to the exhaust port of the boiler 54, and the exhaust port of the primary economizer 64 corresponds to the chimney The air inlet of 63 is corresponding, and the first-level water inlet...

Embodiment 2

[0045] Embodiment two: as attached figure 1 , 2 As shown, a method of using the above-mentioned energy-saving device includes the following steps:

[0046] a. water injection;

[0047] b. run;

[0048] c. Condensed water collection: During operation, the condensed water in the condenser 65 flows through the condensed water collecting pipe 103 and flows into the condensed water tank 1. When half of the condensed water in the condensed water tank 1 is collected, close the first circulation valve 31 and The second circulation valve 32, open the third circulation valve 33 and the dosing pump 6, add sodium hydroxide solution in the condensed water tank 1 for 1 minute to 3 minutes; close the first circulation valve 31, the third circulation valve 33 and the dosing pump Pump 6, open the second circulation valve 32 and the self-circulation pump 27, and circulate the neutralized condensed water in the condensed water tank 1 for 3 minutes to 7 minutes; close the second circulation va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com