Polyurethane coating composition

A technology of polyurethane coating and composition, applied in the field of polyurethane coating composition, can solve the problems of usability limitation, small recoating window, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] The invention is illustrated by the following examples. It is to be understood that specific examples, materials, amounts and procedures are to be interpreted broadly in accordance with the scope and spirit of the invention as set forth herein. All parts and percentages are by weight and all molecular weights are weight average molecular weights unless otherwise stated. Unless otherwise stated, all chemicals used were commercially available, eg, from Sigma-Aldrich, St. Louis, MO.

[0067] testing method

[0068] Unless otherwise indicated, the following test methods were used in the following examples.

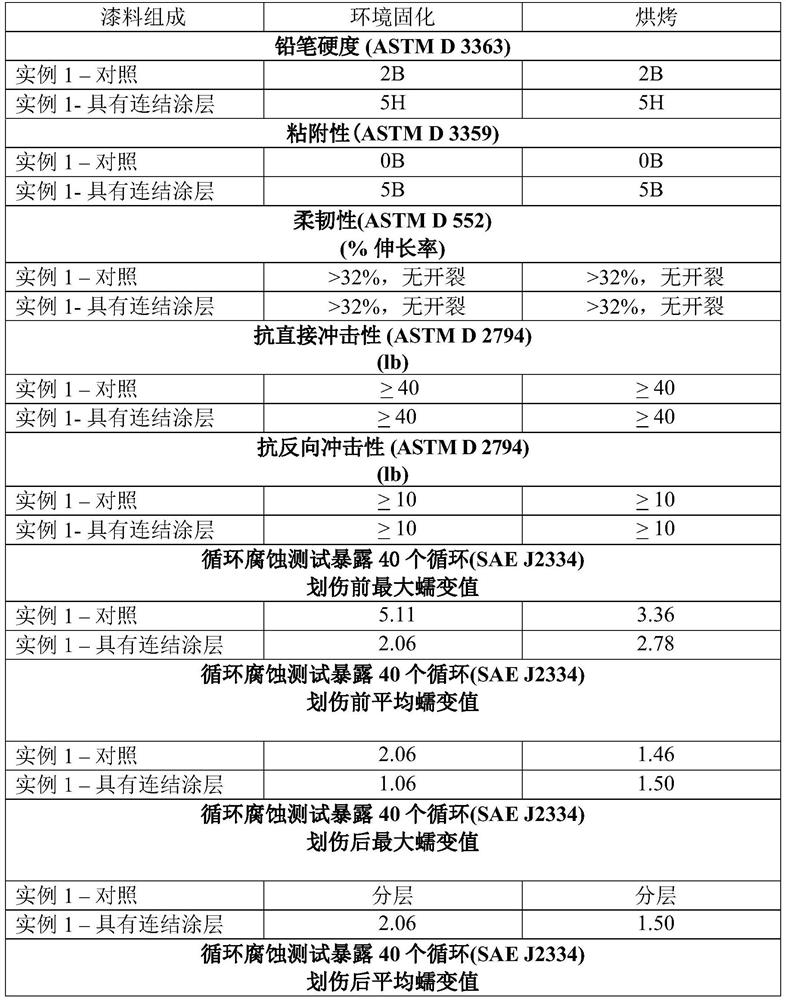

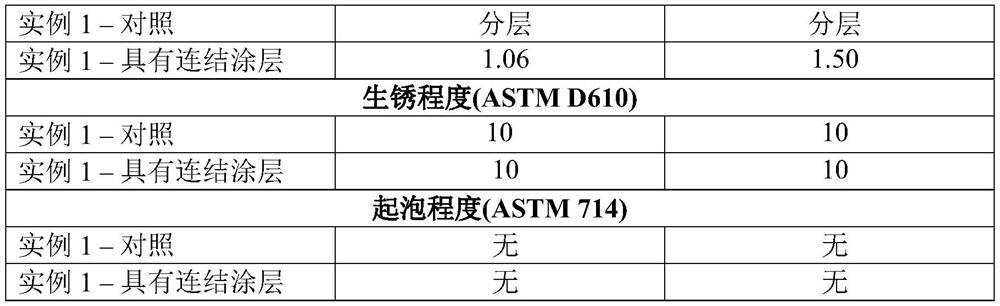

[0069] Laboratory Cyclic Corrosion Testing

[0070] Cyclic corrosion was examined using standard methods (ie, Society of Automotive Engineers (SAE) Surface Vehicle Standard J2334 Exterior Surface Corrosion Laboratory Test). The test is cyclic in nature, ie exposing the test sample to a climate that changes over time. As used herein, test samples were subjected to ...

example 1

[0081]Example 1. Preparation of Urethane Tie Coating Composition #1

[0082] Two-component urethane coating compositions were prepared according to the following method. By combining 91.30 g of CAPA 3050 polyester polyol (Perstorp), 73.04 g of methyl amyl ketone, 16.74 g of butyl acetate, 804.86 g of tert-butyl acetate and 11.22 g of 2,4-pentanedione, to prepare component A. To this mixture were added 0.32 g DUROCT cobalt 12% NX (Dura Chemicals, Emeryville CA) and 0.170 g dibutyltin dilaurate as catalysts, and 0.46 g COROC A-620-A2 (Arkema) as flow control agent, and 1.89 g TINUVIN 292 (BASF).

[0083] Part B was prepared by combining 321.40 g of TOLONATE HDT 90 polyisocyanate (Vencorex) and 83.40 g of butyl acetate.

[0084] Components A and B are then combined to produce a two-component tie coating composition. The composition had 27.28 wt% non-volatile material, 374 g / L VOC and a 16s viscosity as measured with a ZAHN Signature #2 series dip cup (Gardner).

example 2

[0085] Example 2. Preparation of Urethane Tie Coating Composition #2

[0086] Two-component urethane coating compositions were prepared according to the following method. By combining 126.7 g of CAPA 4101 polyester polyol (Perstorp), 73.04 g of methyl amyl ketone, 16.74 g of butyl acetate, 769.40 g of tert-butyl acetate and 11.22 g of 2,4-pentanedione, to prepare component A. To this mixture were added 0.32 g DUROCT cobalt 12% NX (Dura Chemicals, Emeryville CA) and 0.17 g dibutyltin dilaurate as catalyst, and 0.46 g COROC A-620-A2 (Arkema) as flow control agent, and 1.89 g TINUVIN 292(BASF)

[0087] Part B was prepared by combining 321.40 g of TOLONATE HDT 90 polyisocyanate (Vencorex) and 83.40 g of butyl acetate.

[0088] Components A and B are then combined to produce a two-component tie coating composition. The composition had 29.68 wt% non-volatile materials and 356 g / L VOC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com