A high-efficiency sapphire crystal processing equipment coolant powder multi-stage sedimentation tank

A technology of sapphire crystal and processing equipment, applied in sedimentation tank, sedimentation tank, sedimentation separation and other directions, can solve the problems of time-consuming and laborious, low production efficiency, blockage of machine tool coolant pipeline, etc., to improve sedimentation effect, convenient and quick replacement, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

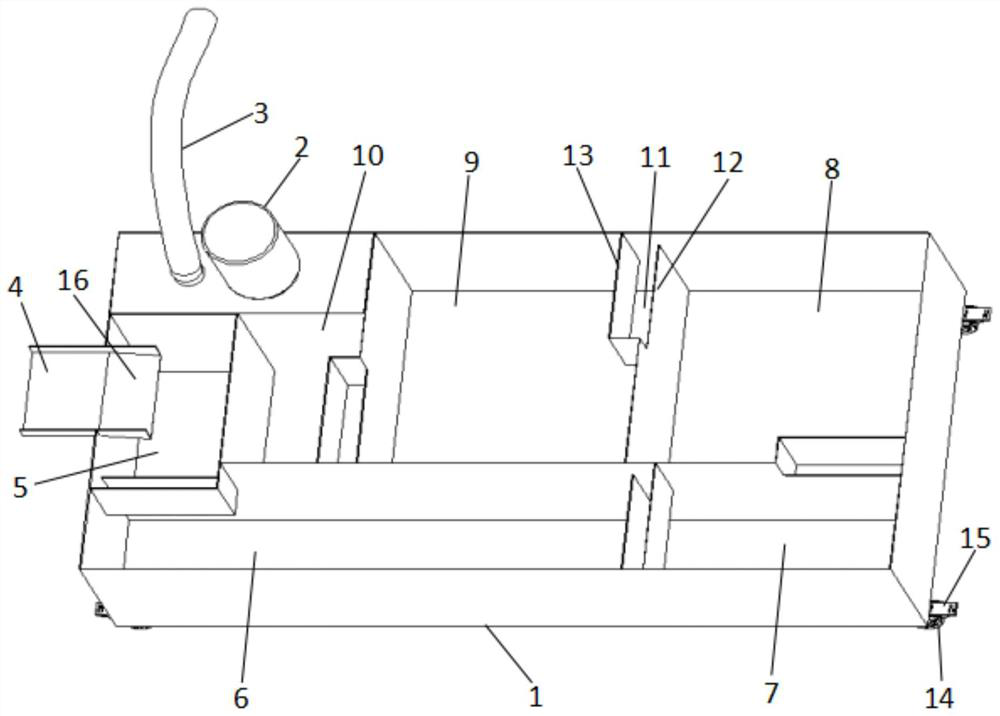

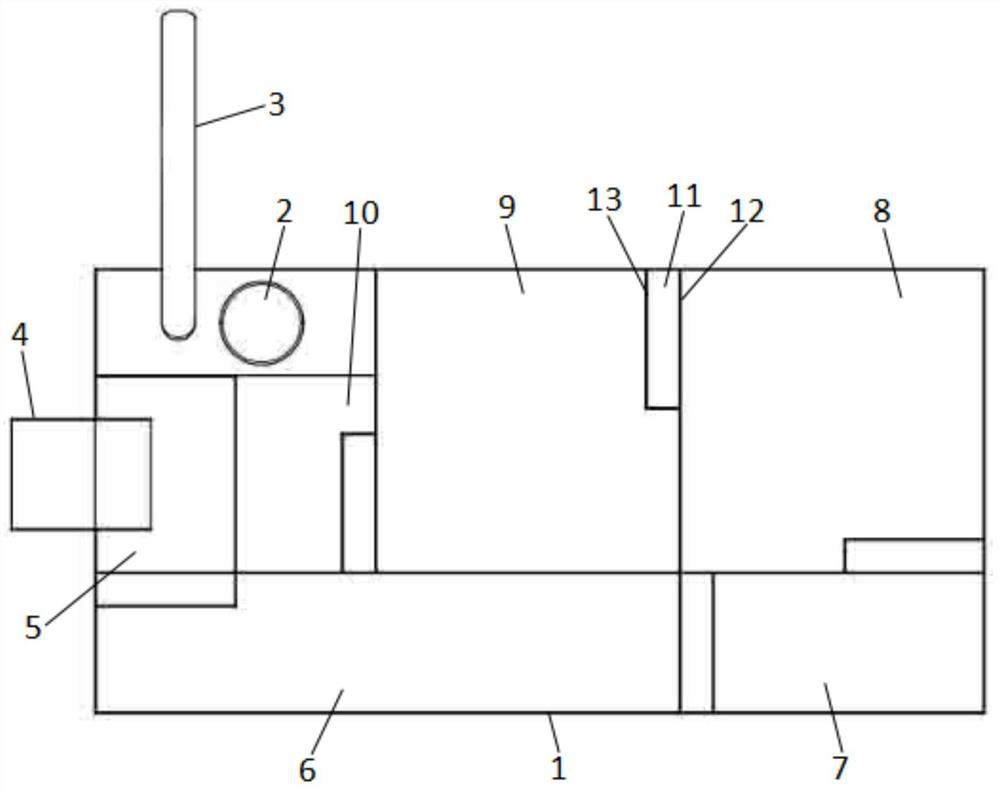

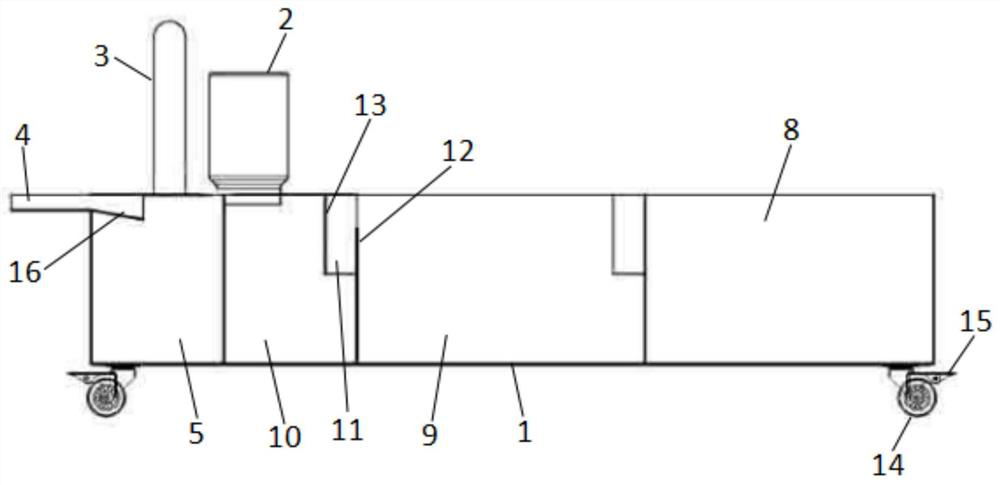

[0029] refer to Figure 1-Figure 4 , a high-efficiency sapphire crystal processing equipment cooling liquid powder multi-stage sedimentation tank of the present invention includes a tank body 1, a cooling liquid pump 2 and a water outlet pipe 3. The coolant pump 2 is used to pump the coolant to the water outlet pipe 3, and the coolant is delivered to the equipment through the water outlet pipe 3 for reuse. One end of the tank body 1 is provided with a drain channel 4 for draining the cooling liquid returned from the equipment. A primary sedimentation chamber 5 is provided below the drainage channel 4 . Specifically, the end of the drainage channel 4 is provided with a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com