Improved process of three-kettle polyester process

A polyester and process technology, which is applied in the field of improvement of the three-pot polyester process, can solve problems such as increased energy consumption and the impact on the activity of titanium-based catalysts, and achieves the effects of low cost, easy implementation, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

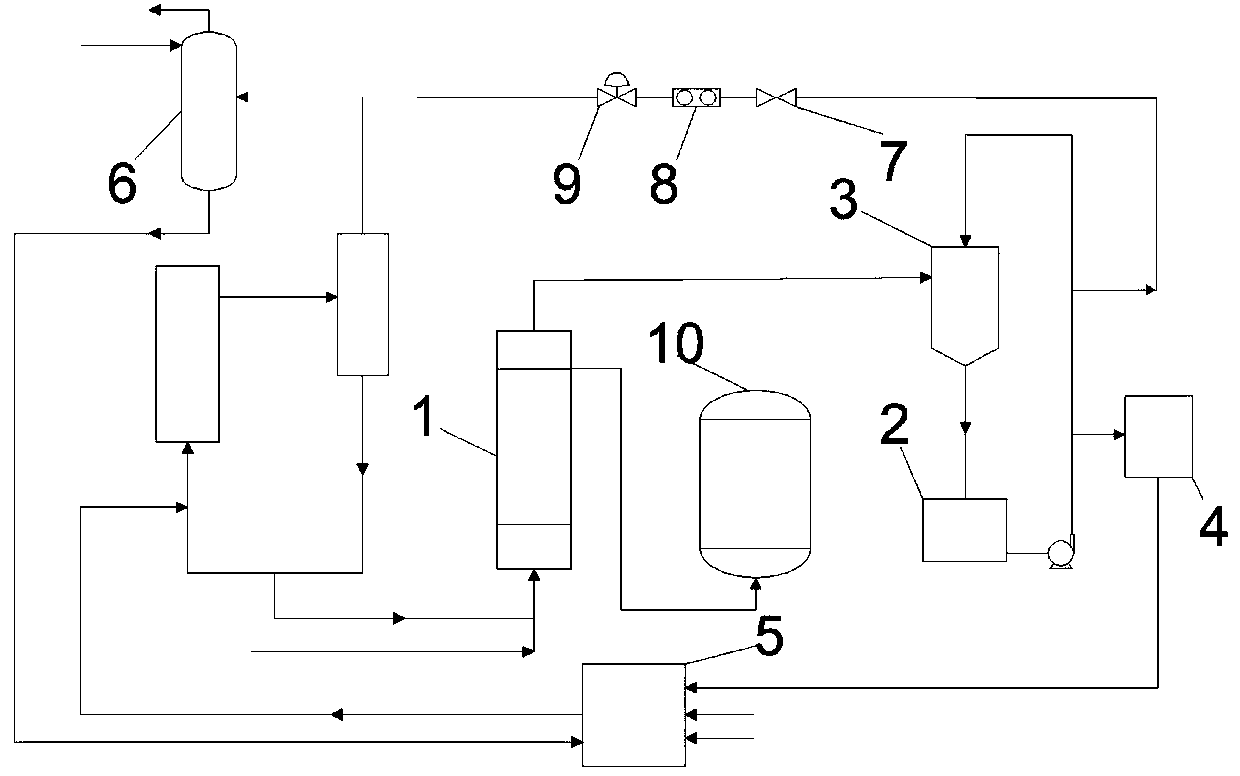

[0022] An improved process for a three-pot polyester process. The raw materials are PTA and EG. The catalyst is a titanium-based polyester catalyst TY-2. The equipment involved includes an esterification kettle, a prepolymerization reactor 1, a final polymerization reactor 10, ethylene glycol and Water separation tower 6 is EG / H 2 O separation tower, pre-polymerization tank spray condenser 3, EG hot well 2, CP recovery tank 4, slurry mixing tank 5, wherein the esterification tank includes a heater and a gas-liquid separation tank.

[0023] PTA, EG sent from outside the system, EG from ethylene glycol and water separation tower 6, and EG from CP recovery tank 4 are fully mixed in slurry mixing tank 5, and sent to esterification at a flow rate of 19.5t / h The heater of the kettle, the raw materials react to generate esterified oligomers, and gasify at the same time, the gasified raw materials enter the gas-liquid separation tank, and after the raw materials enter the gas-liquid s...

Embodiment 2

[0033]An improved process for a three-pot polyester process. The raw materials are PTA and EG. The catalyst is a titanium-based polyester catalyst TY-2. The equipment involved includes an esterification kettle, a prepolymerization reactor 1, a final polymerization reactor 10, ethylene glycol and Water separation tower 6 is EG / H 2 O separation tower, pre-polymerization tank spray condenser 3, EG hot well 2, CP recovery tank 4, slurry mixing tank 5, wherein the esterification tank includes a heater and a gas-liquid separation tank.

[0034] PTA, EG sent from outside the system, EG from ethylene glycol and water separation tower 6, and EG from CP recovery tank 4 are fully mixed in slurry mixing tank 5, and sent to esterification at a flow rate of 19.5t / h The heater of the kettle, the raw materials react to generate esterified oligomers, and gasify at the same time, the gasified raw materials enter the gas-liquid separation tank, and after the raw materials enter the gas-liquid se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com