Water-based two-component full-matte varnish and preparation method thereof

A two-component, clear topcoat technology, applied in coatings and other directions, can solve the problems of too large difference in transparency, poor film transparency, affecting product quality, etc., to improve crack resistance, good density, and film forming time. and the effect of a short drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

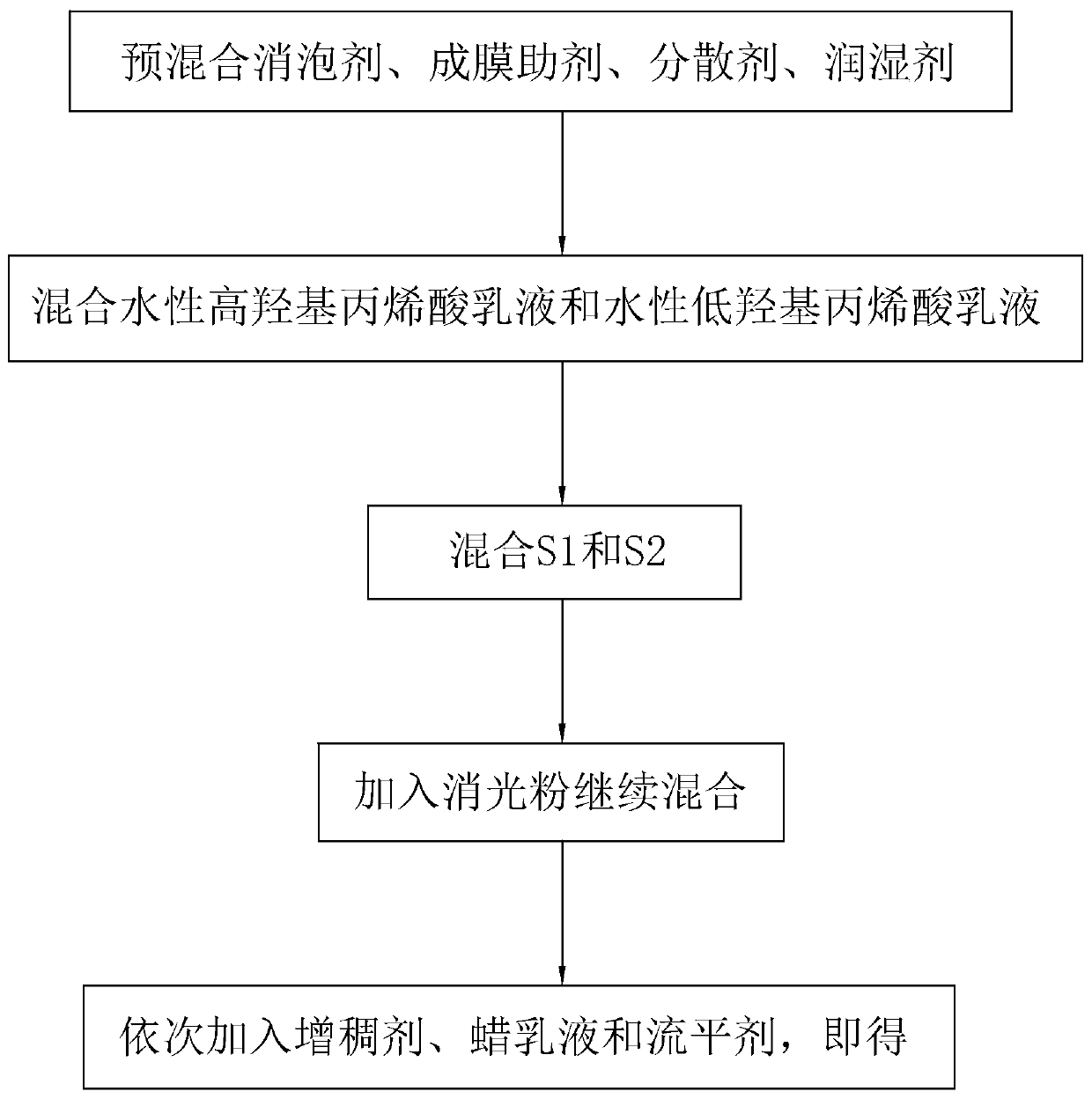

[0055]Embodiment 1: A kind of water-based two-component matte varnish, each component and its corresponding parts by weight are as shown in Table 1, and are prepared through the following steps:

[0056] S1, according to Table 1, pre-mix the defoamer, film-forming aid, dispersant, wetting agent and 1 / 5 deionized water in corresponding parts by weight, and stir evenly for later use;

[0057] S2, according to Table 1, put the water-based high-hydroxyl acrylic emulsion and the water-based low-hydroxyl acrylic emulsion in corresponding parts by weight into the dispersion tank, and disperse at a speed of 400r / min for 10min;

[0058] S3, increase the speed of the disperser to 600r / min, add the pre-mixed mixture in the step S1 into the dispersion cylinder, and disperse at a high speed of 1000r / min for 25 minutes;

[0059] S4, reduce the speed of the disperser to 400r / min, put in fumed silica, clean the edge of the dispersion tank with 1 / 5 of deionized water after feeding and add it t...

Embodiment 2-6

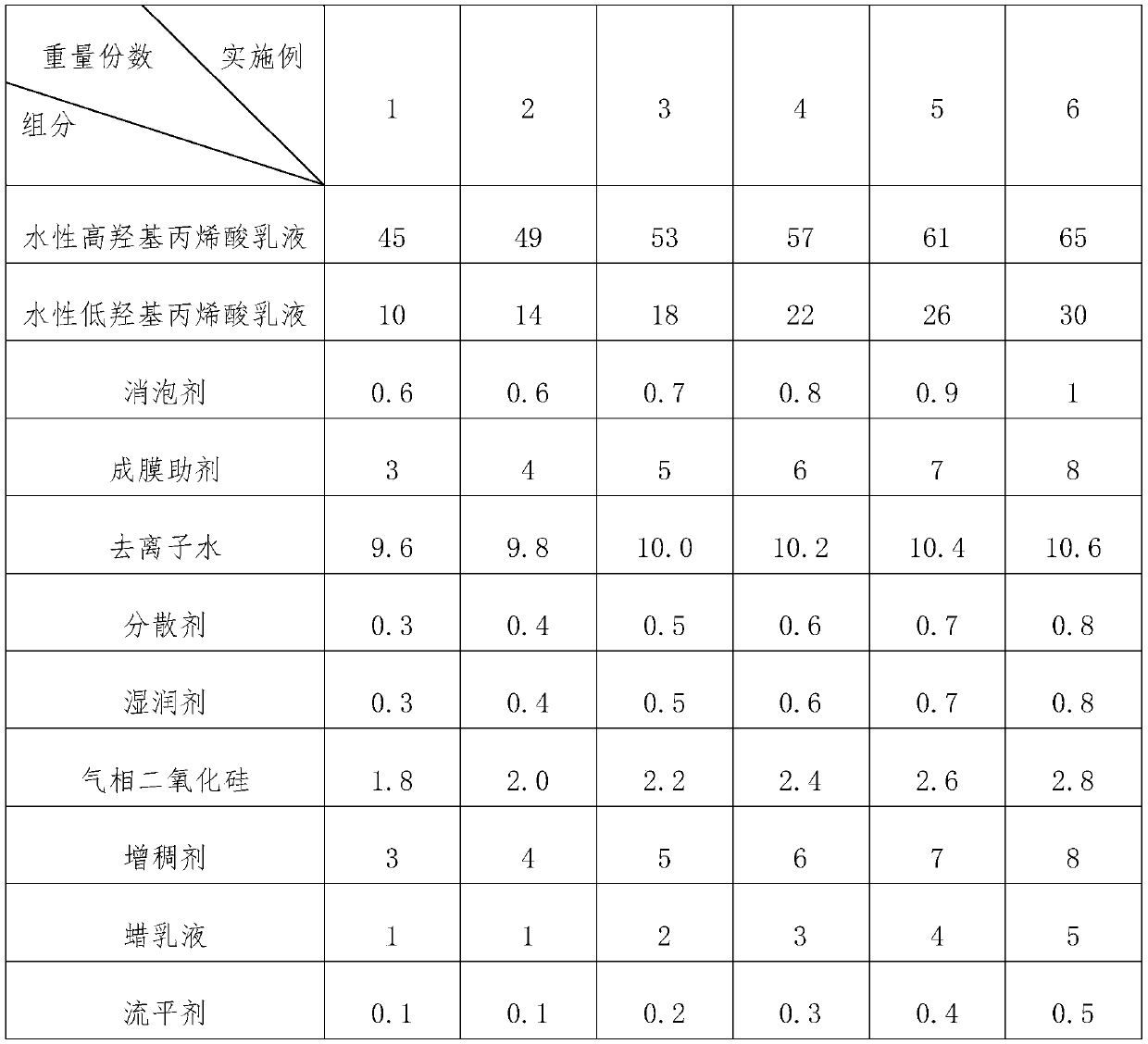

[0062] Example 2-6: A water-based two-component matt clear finish, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0063] Each component and parts by weight thereof in table 1 embodiment 1-6

[0064]

Embodiment 7

[0065] Embodiment 7: A kind of water-based two-component matte varnish, the difference from Example 1 is that it is prepared through the following steps:

[0066] S1, according to Table 1, pre-mix the defoamer, film-forming aid, dispersant, wetting agent and 1 / 5 deionized water in corresponding parts by weight, and stir evenly for later use;

[0067] S2, according to Table 1, put the water-based high-hydroxyl acrylic emulsion and the water-based low-hydroxyl acrylic emulsion in corresponding parts by weight into the dispersion tank, and disperse at a speed of 500r / min for 5min;

[0068] S3, increase the speed of the disperser to 700r / min, add the pre-mixed mixture in the step S1 into the dispersion cylinder, and disperse at a high speed of 1200r / min for 15 minutes;

[0069] S4, reduce the speed of the disperser to 500r / min, put in fumed silica, use 1 / 5 deionized water to clean the edge of the dispersion tank and add it to the dispersion tank after feeding, increase the speed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com