Ultra-fine grain high-strength high-entropy alloy with magnetism and preparing method of ultra-fine grain high-strength high-entropy alloy

A high-entropy alloy and high-strength technology, applied in the field of high-entropy alloys, to achieve good comprehensive mechanical properties, low forming temperature, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

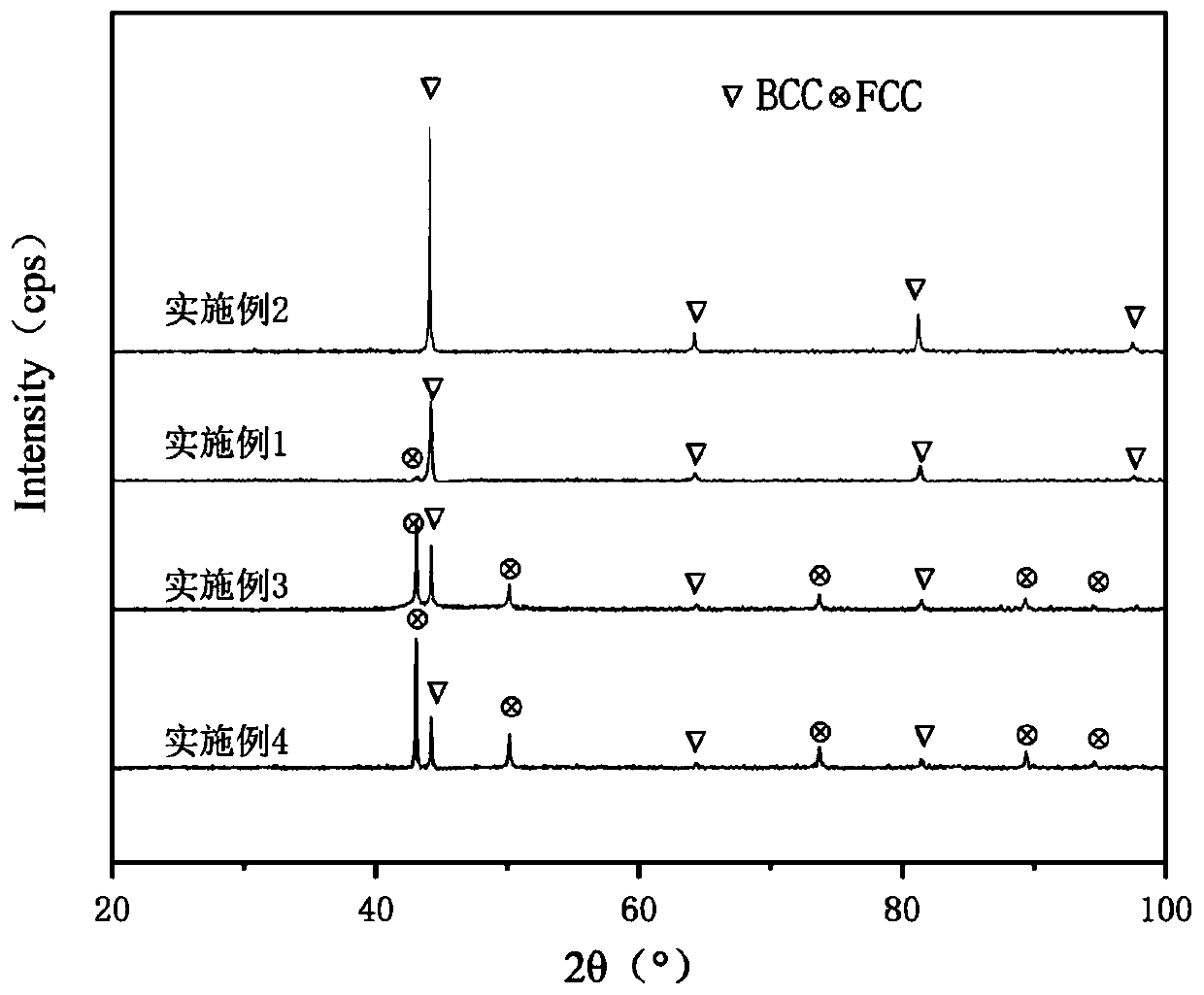

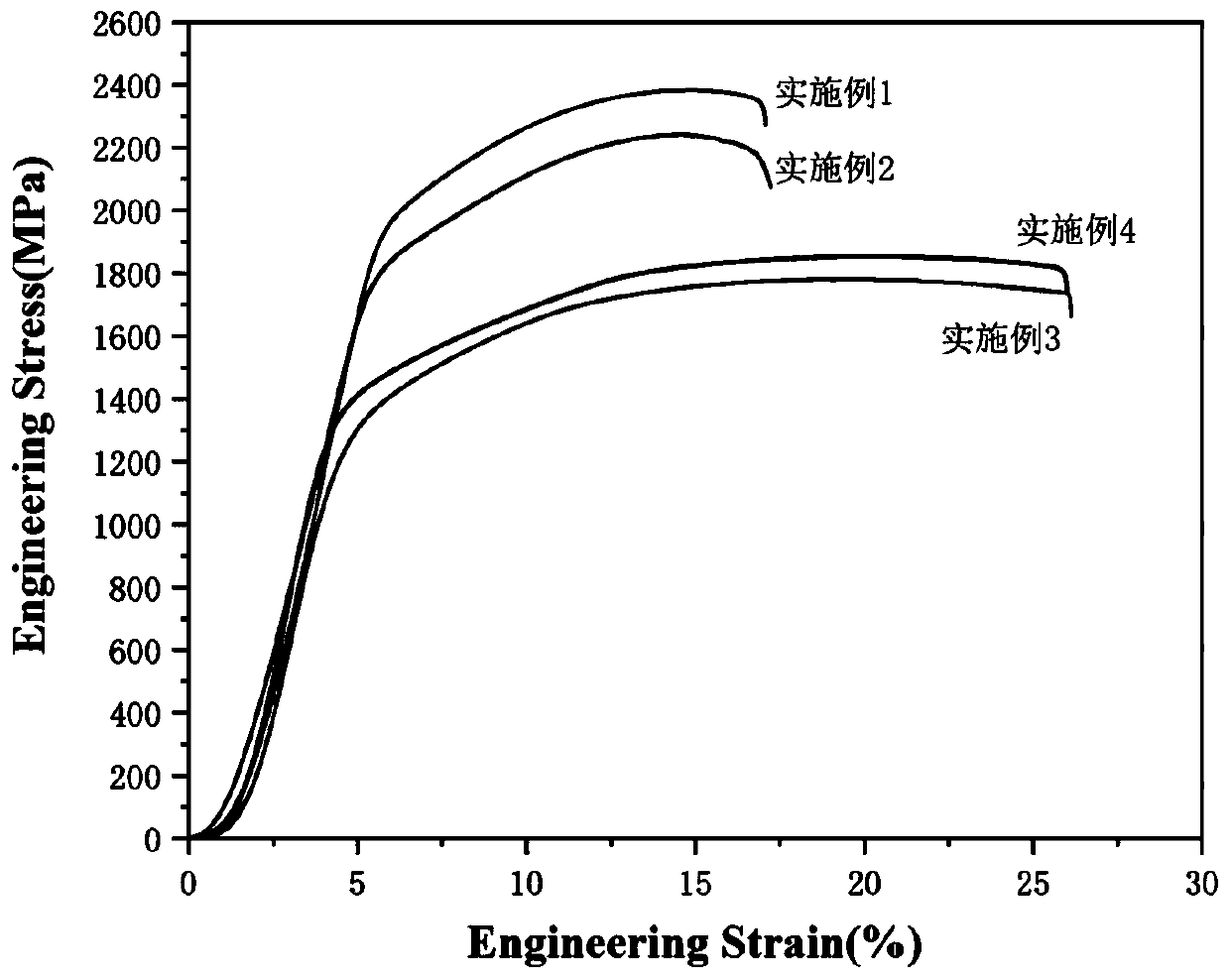

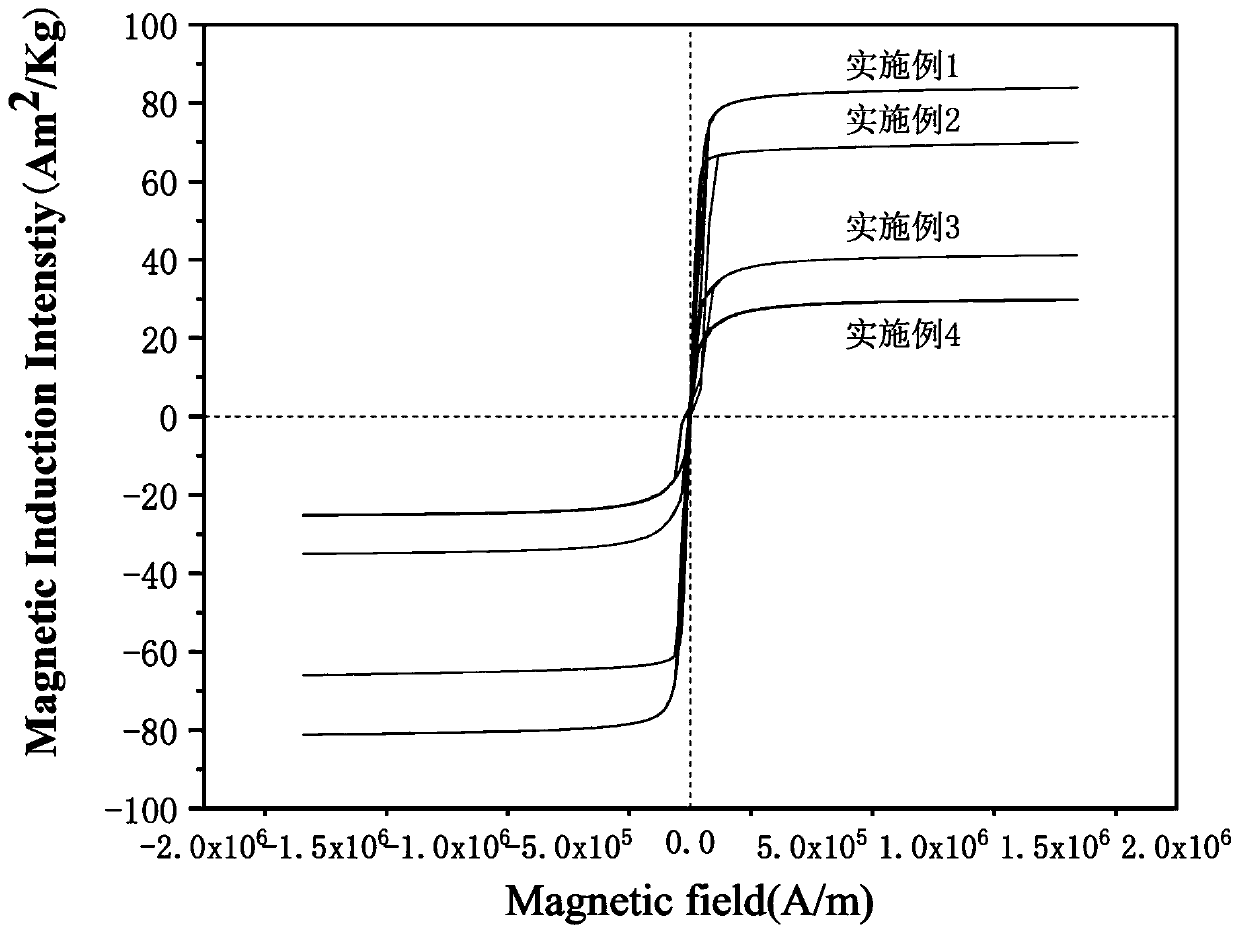

[0030] A magnetic high-strength ultrafine grain (Fe 50 mn 30 Cr 10 co 10 ) 100-X al X High-entropy alloys, the composition of which is (Fe 50 mn 30 Cr 10 co 10 ) 84 al 16 , the specific steps of the method are as follows:

[0031] Step 1: Mix the powder

[0032] Weigh the elemental powder according to the atomic percentage content of Fe 42%, Mn 25.2%, Cr 8.4%, Co 8.4%, Al 16%, the powder purity is 99.99wt%, and the particle size is less than 325 mesh. The weighed powder was placed in a V-type powder mixer for dry mixing for 16 hours.

[0033] Step 2: Mechanical Alloying

[0034] Put the uniformly mixed powder into a ball mill jar, and then use a planetary ball mill for ball milling. The main ball milling parameters are controlled as follows:

[0035] Atmosphere control: Before the ball milling starts, the ball mill tank is evacuated and filled with argon for protection;

[0036] Ball material ratio: 20:1;

[0037] Ball mill speed: 300rpm;

[0038] Ball milling...

Embodiment 2

[0049] A magnetic high-strength ultrafine grain (Fe 50 mn 30 Cr 10 co 10 ) 100-X Al X High-entropy alloys, the composition of which is (Fe 50 mn 30 Cr 10 co 10 ) 80 Al 20 , the specific steps of the method are as follows:

[0050] Step 1: Mix the powder

[0051] Weigh the elemental powder according to the atomic percentage content of Fe 40%, Mn 24%, Cr 8%, Co 8%, Al 20%, the powder purity is 99.99wt%, and the particle size is less than 325 mesh. The weighed powder was placed in a V-type powder mixer for dry mixing for 20 h.

[0052] Step 2: Mechanical Alloying

[0053] Put the uniformly mixed powder into a ball mill jar, and then use a planetary ball mill for ball milling. The main ball milling parameters are controlled as follows:

[0054] Atmosphere control: Before the ball milling starts, the ball mill tank is evacuated and filled with argon for protection;

[0055] Ball material ratio: 15:1;

[0056] Ball mill speed: 200rpm;

[0057] Ball milling time: 50h...

Embodiment 3

[0068] A magnetic high-strength ultrafine grain (Fe 50 mn 30 Cr 10 co 10 ) 100-X Al X High-entropy alloys, the composition of which is (Fe 50 mn 30 Cr 10 co 10 ) 88 Al 12 , the specific steps of the method are as follows:

[0069] Step 1: Mix the powder

[0070] Weigh the elemental powder according to the atomic percentage content of Fe 44%, Mn 26.4%, Cr 8.8%, Co 8.8%, Al 12%, the powder purity is 99.99wt%, and the particle size is less than 325 mesh. The weighed powder was placed in a V-type powder mixer for dry mixing for 24 hours.

[0071] Step 2: Mechanical Alloying

[0072] Put the uniformly mixed powder into a ball mill jar, and then use a planetary ball mill for ball milling. The main ball milling parameters are controlled as follows:

[0073] Atmosphere control: Before the ball milling starts, the ball mill tank is evacuated and filled with argon for protection;

[0074] Ball material ratio: 10:1;

[0075] Ball mill speed: 250rpm;

[0076] Ball milling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com