Construction method for steel guide wall foundation of sea area deep-water anchor foundation

A technology for foundation construction and steel guide wall, applied in foundation structure engineering, sheet pile wall, soil protection and other directions, can solve the problems of construction quality accident, high cost of cofferdam island building and demolition, long construction period, etc., to ensure project safety and quality, high engineering practical significance, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

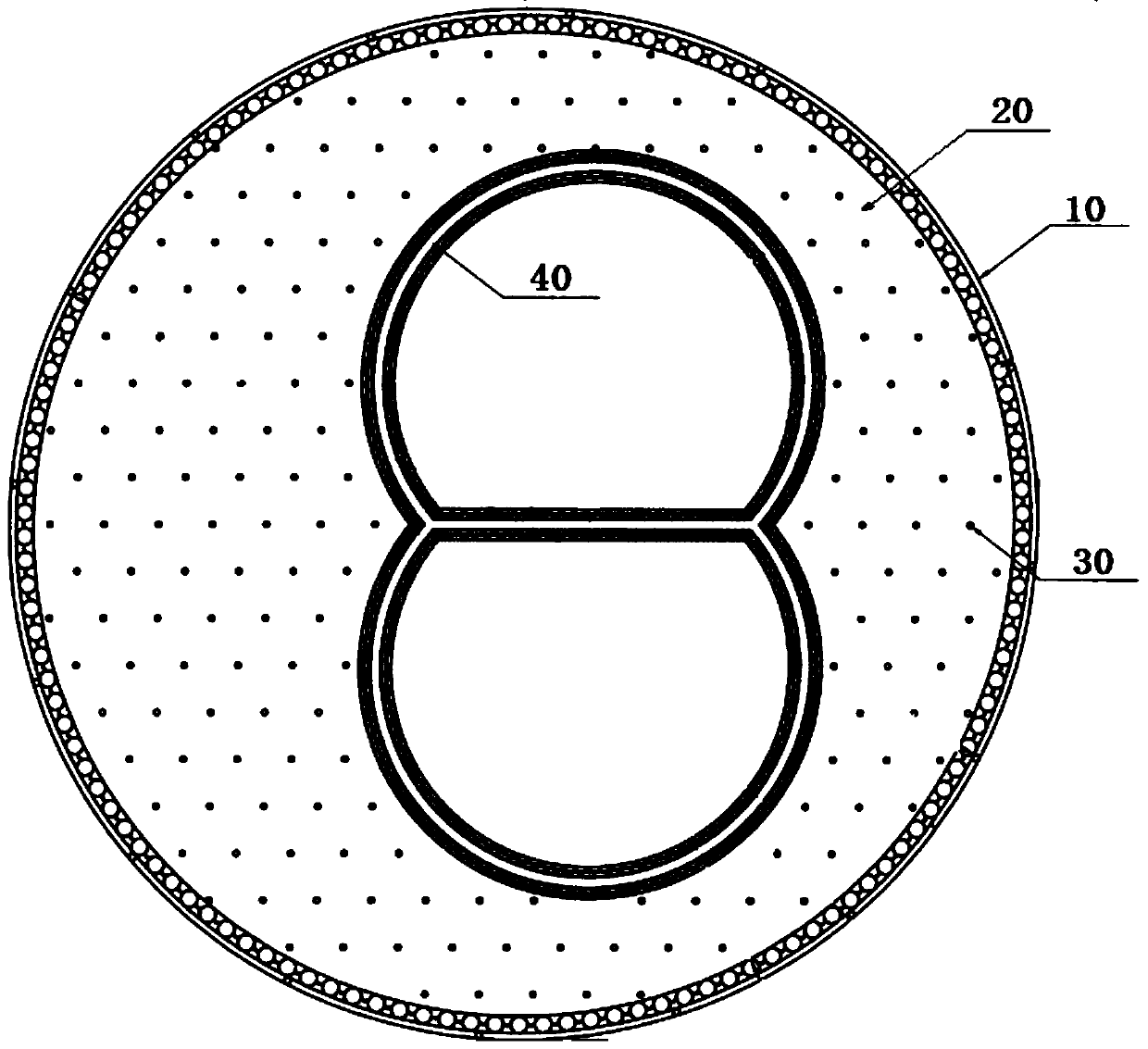

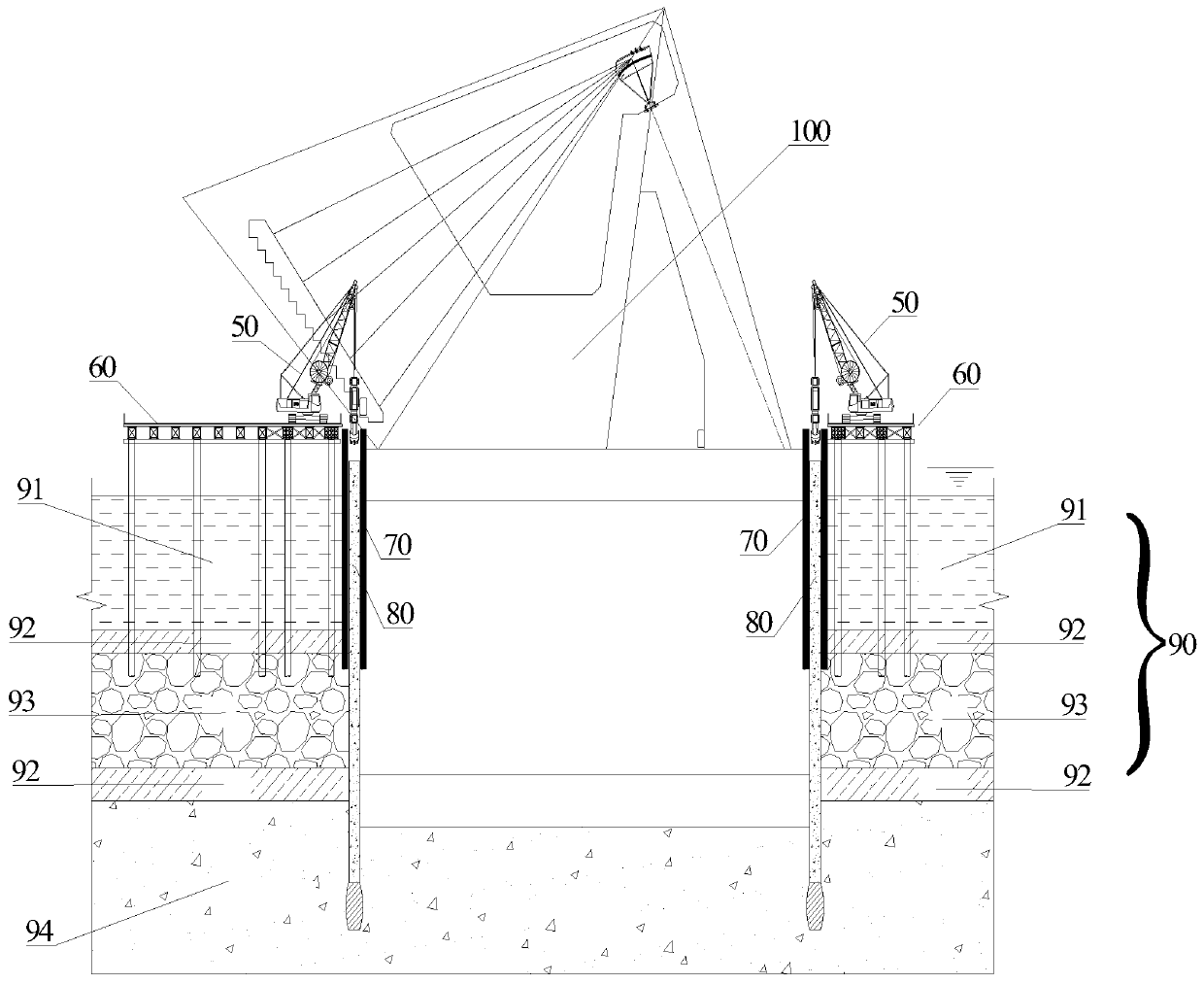

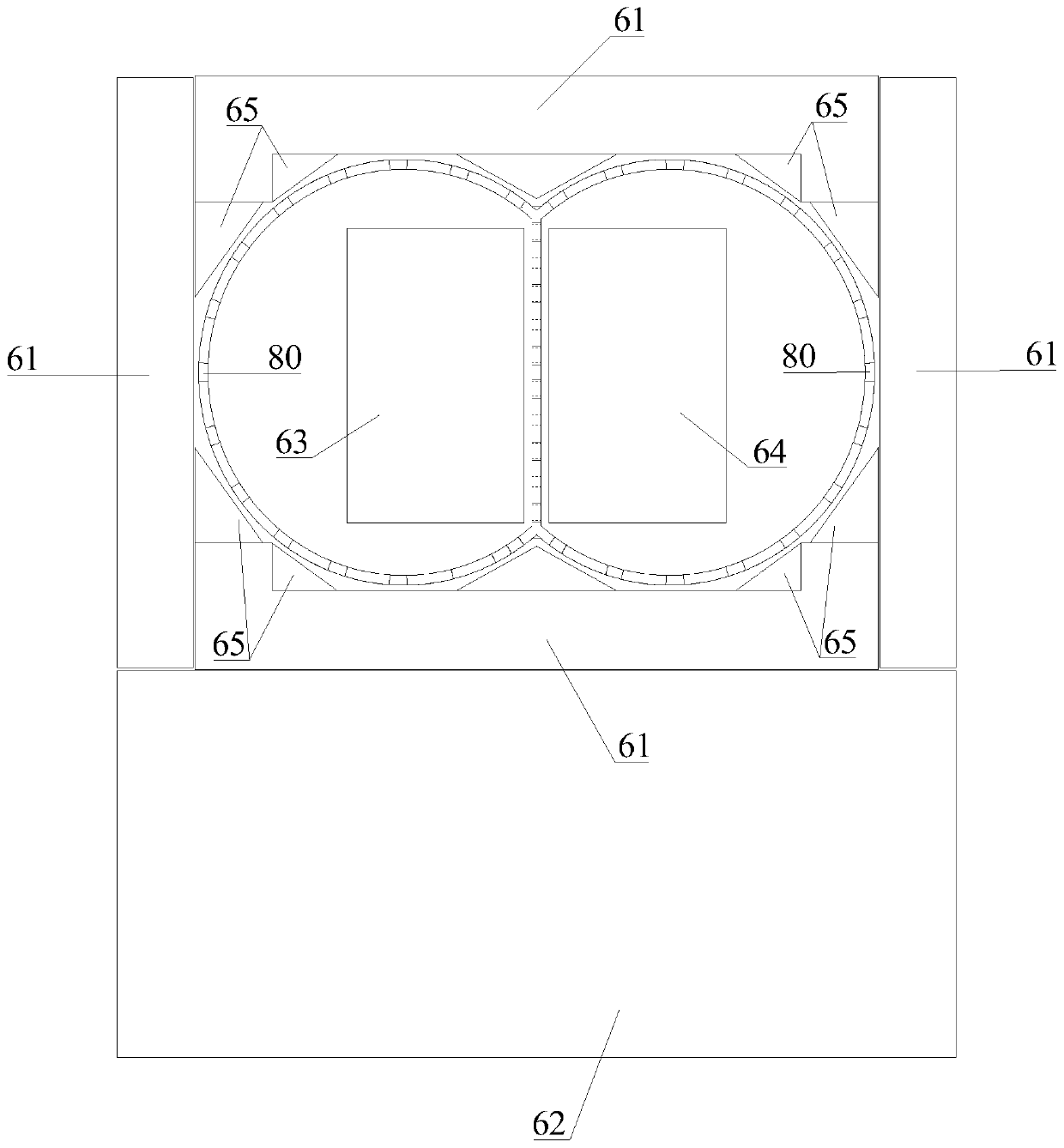

[0025] The invention discloses a steel guide wall 70 foundation construction method for deep water anchorage foundations in sea areas, which is applied to the anchorage foundation construction of suspension bridges in deep water sea areas, and a ground connection wall foundation with a steel guide wall 70 as a guide wall structure is constructed to come For the excavation of the foundation pit of the anchorage foundation in the later stage, it can realize the functions of support, water and waves. The present invention can also be popularized and applied to the groove-forming construction of ground wall foundations in shallow water areas and convention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com