Flexible direct-current cable with cooling function

A flexible DC and functional technology, applied in the direction of power cables including optical transmission components, power cables, insulated cables, etc., can solve problems such as impact, loss of national economy and residents' lives, and accelerated thermal aging of cable insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

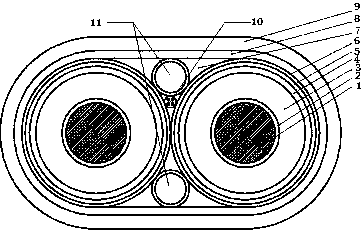

[0017] A flexible DC cable with self-cooling function (see attached figure 1 ), including a cable core, a cooling duct 11 and a temperature-measuring optical fiber unit 10, the cable core includes a conductor 1, the conductor is covered with a conductor shielding layer 2, and the outside of the conductor shielding layer is covered with an insulating layer 3, and the insulation The outer side of the layer is covered with an insulating shielding layer 4, the outer side of the insulating shielding layer is covered with a semi-conductive buffer layer 5, the outer side of the semi-conductive buffer layer is covered with a metal shielding layer 6, the cable core, cooling pipe and the temperature measuring optical fiber unit are all wrapped in the tape layer 8, the space inside the tape layer is filled with a cable filling rope 7, and the outside of the tape layer is covered with an outer sheath 9; The temperature measuring optical fiber unit is connected with a temperature monitorin...

Embodiment 2

[0020] This embodiment is basically the same as Embodiment 1, except that in this embodiment, the outer sheath is a polyethylene sheath, and the outside of the outer sheath is covered with asphalt-coated fiber hemp rope. This embodiment increases the anti-corrosion performance of the cable. The high-density polyethylene outer sheath material has a compact molecular structure and has very strong corrosion resistance. At the same time, the fiber hemp rope coated with asphalt is also a corrosion-resistant material. The cable insulation Under the protection of the two-layer structure, the wire core can still operate normally in the environment of soaking in seawater for a long time, providing guarantee for the long-term stable operation of the DC cable line.

Embodiment 3

[0022] This embodiment is basically the same as Embodiment 1, except that in this embodiment, the outer sheath is a polyethylene sheath of self-sensing temperature masterbatch. The self-sensing temperature color masterbatch polyethylene sheath can be used as an auxiliary. When there is still an ultra-high temperature in the case of automatic cooling, or when there is a problem with self-cooling, the temperature drop can be avoided through the self-sensing temperature color masterbatch polyethylene sheath. further up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com