Ultrasonic cavitation-assisted ultrasonic magnetic polishing method for microstructure molds

An ultrasonic-assisted microstructure technology, applied in the field of precision manufacturing, can solve the problems of inability to achieve the polishing effect and meet the high-quality processing requirements of the microstructure mold surface, so as to improve the quality of the polished surface, increase the speed of the polishing process, and facilitate the removal of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

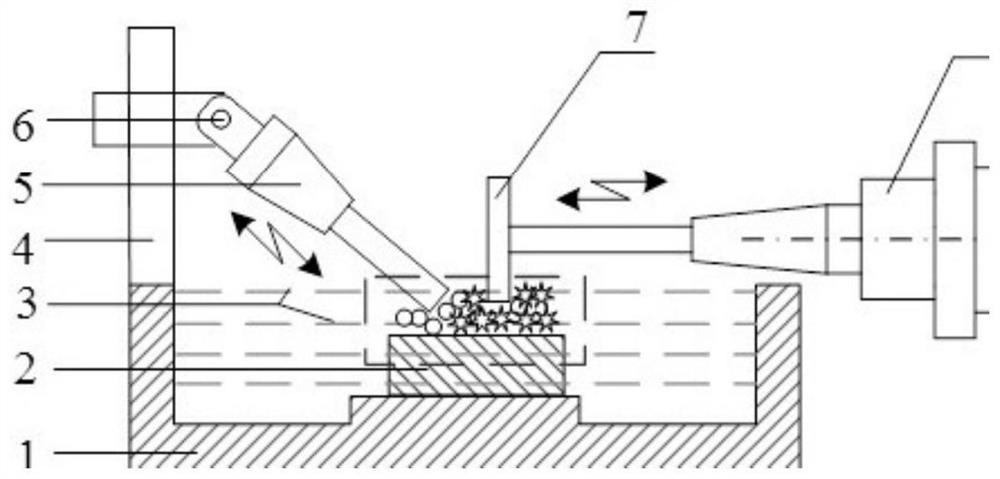

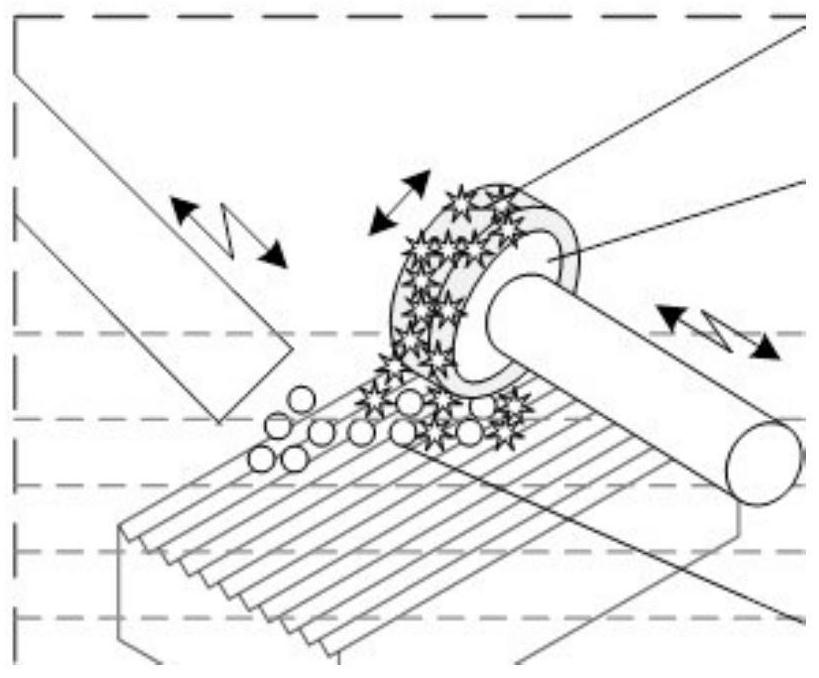

[0023] Attached below Figure 1-2 Examples are also given to describe the present invention in detail.

[0024] (1) The annular permanent magnet 7 is connected with the end of the ultrasonic spindle 8 of the machine tool through the aluminum disc 10. The annular permanent magnet 7 has a diameter of 50-100 mm, and magnetic abrasive particles 9 are adsorbed around it.

[0025] (2) Fix the microstructure mold 2 to be polished on the bottom platform of the water tank 1 filled with the polishing fluid 3, and ensure that the water level of the polishing fluid 3 exceeds the surface of the microstructure mold 2 by 10-20mm. The mold material is tungsten carbide cemented carbide. Polishing liquid 3 is made of nano-SiO 2 , dispersant, water, etc., SiO 2 Particle size is 50~100nm, SiO 2 The content of abrasive grains is 2% to 10%.

[0026] (3) Adjust the position and posture of the ultrasonic vibrator 5 to ensure that its end is located on the side of the advancing direction of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com