Universal gripper for vehicle door

A technology for car doors and grippers, which is applied in the direction of manipulators, chucks, manufacturing tools, etc. It can solve the problem that fixed grippers cannot be applied to doors of different models, and achieve the effects of reducing programming time, improving production cycle time, and reducing the amount of debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

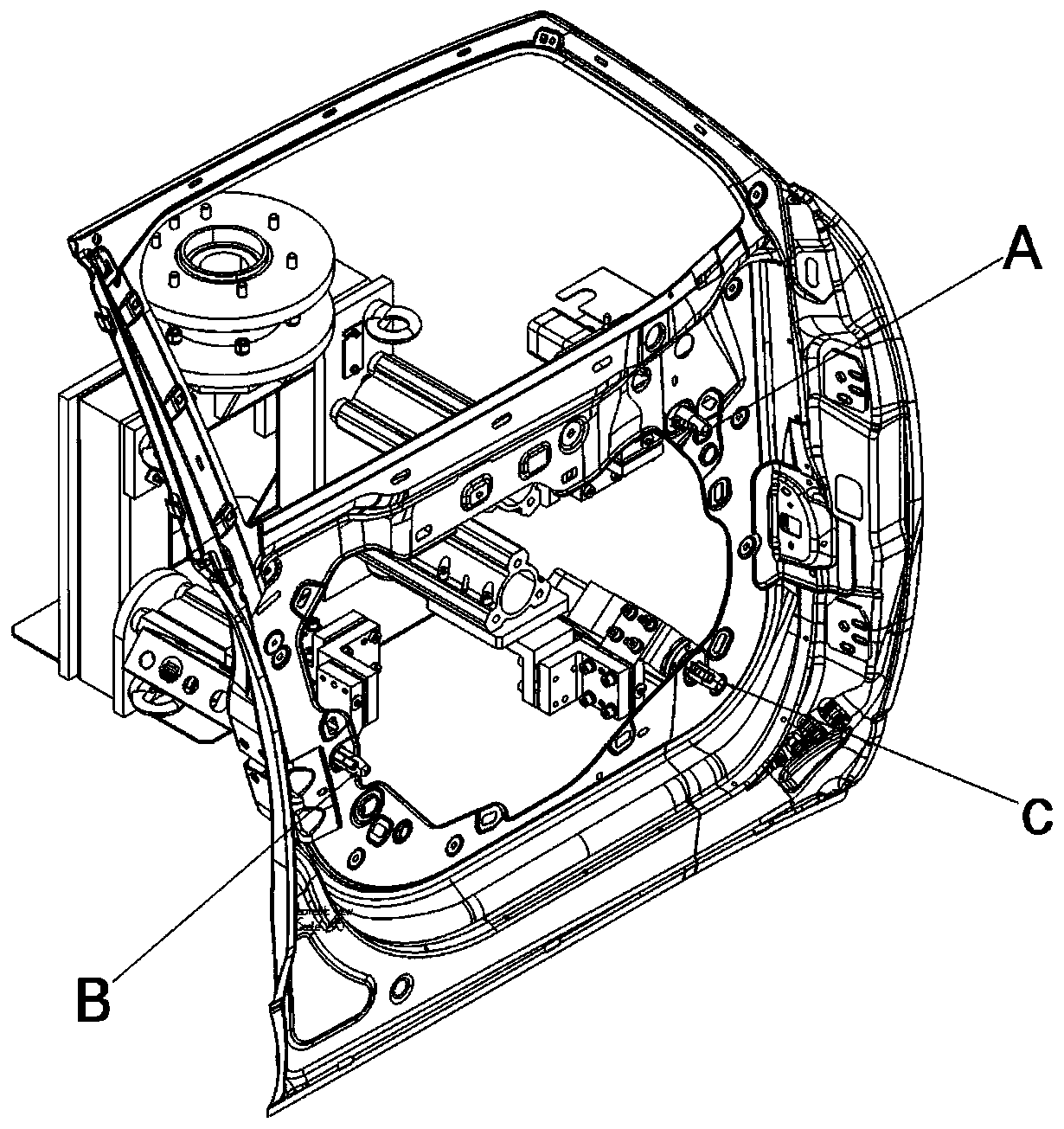

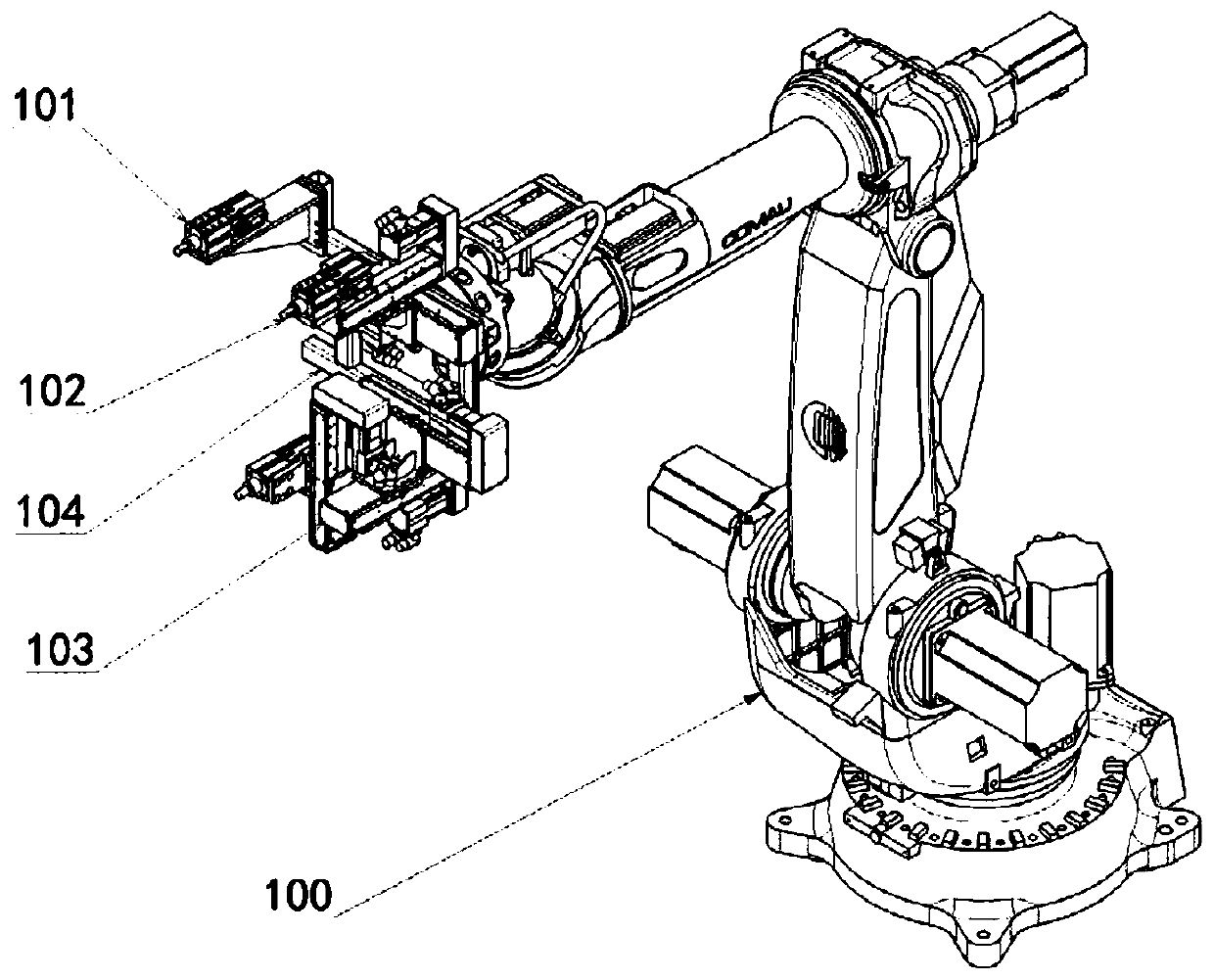

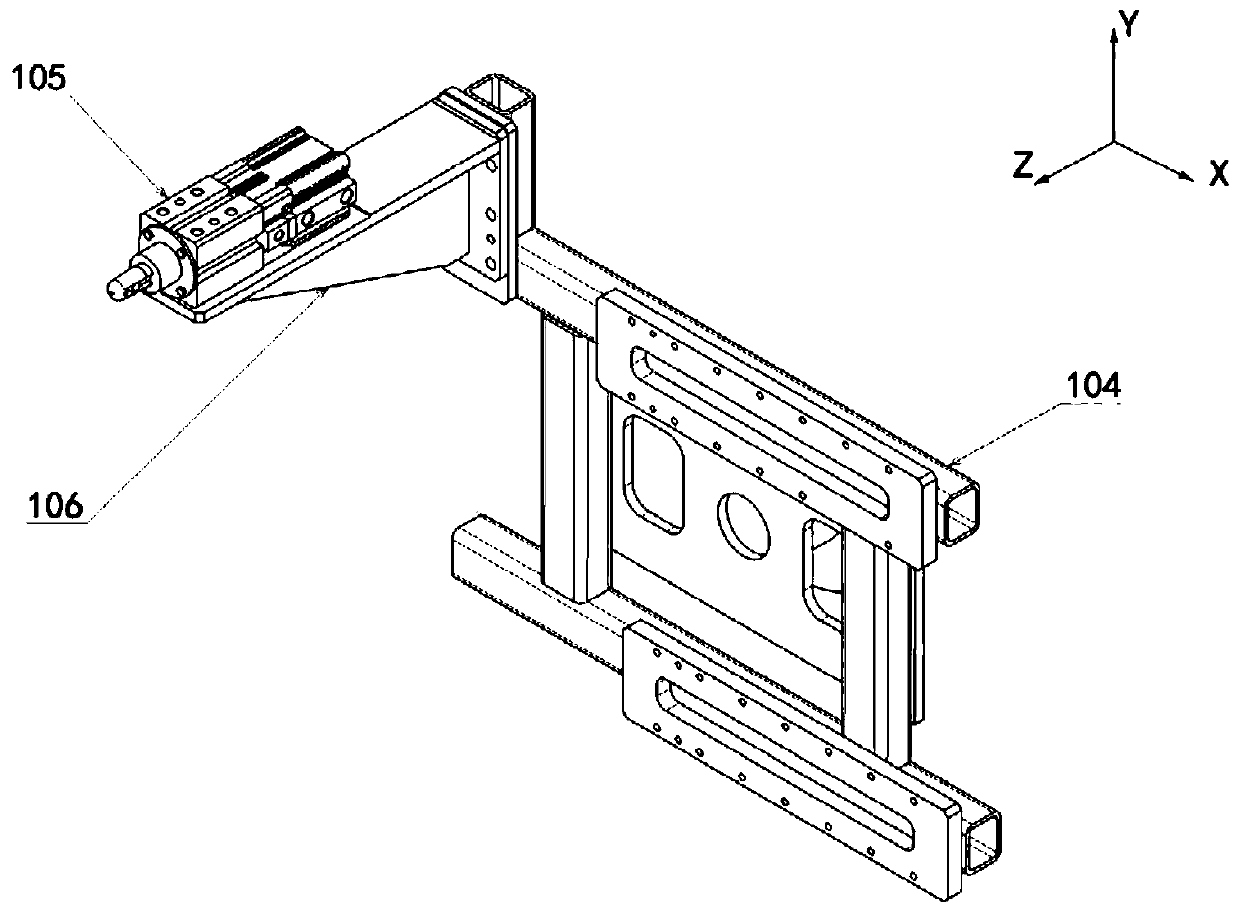

[0031] like figure 2 As shown, the present invention defines three directions as the width direction X, the height direction Y and the thickness direction Z. The invention is a general gripper for car doors, which adopts a linear drive system to realize the movement of the gripping point, so that the gripper can adapt to the gripping section width difference ΔX, height difference ΔY and thickness difference ΔZ existing in doors of various models , that is, regardless of the arbitrary changes of the three grasping points A, B, and C in the X, Y, and Z directions, the universal gripper described in the present invention can be adjusted in three directions accordingly to realize a universal gripper corresponding to Grab different car doors.

[0032] The present invention consists of a mechanical arm body 100 , a first end effector unit 101 , a second end effector unit 102 , a third end effector unit 103 and a connecting flange 104 .

[0033] The connecting flange 104 is a mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com