Recyclable eva vitrimer foam material and its preparation method and recycling method

A foaming material and foaming agent technology, applied in the field of foaming materials, can solve the problems that cannot be solved well, cannot be directly recycled, cannot directly realize the recyclable use of EVA foam body materials, etc., and achieves excellent mechanical strength, Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Weigh 100 parts of ethylene-vinyl acetate copolymer, 15 parts of tripropyl phosphate, and 0.5 parts of zinc acetylacetonate by weight and pre-mix them in a beaker for 5-10 minutes;

[0028] Step 2: The ethylene-vinyl acetate copolymer premixed in step 1, the crosslinking agent and the catalyst are reactively blended in an extruder for 10 minutes, and the reaction temperature is 150° C. to obtain an EVA vitrimer material;

[0029] Step 3: get the EVA vitrimer material that obtains in the step 2 of 100 parts and carry out mechanical blending in extruder with 20 parts of heat-expandable microspheres, 2 parts of foaming aid zinc oxide and 5 parts of filler white carbon black, The blending temperature is 90°C, and the blending time is 5 minutes;

[0030] Step 4: The kneaded mixture in step 3 was molded and foamed at 150°C for 10 minutes to obtain the original EVA vitrimer foam material, which was named Original EVA foam;

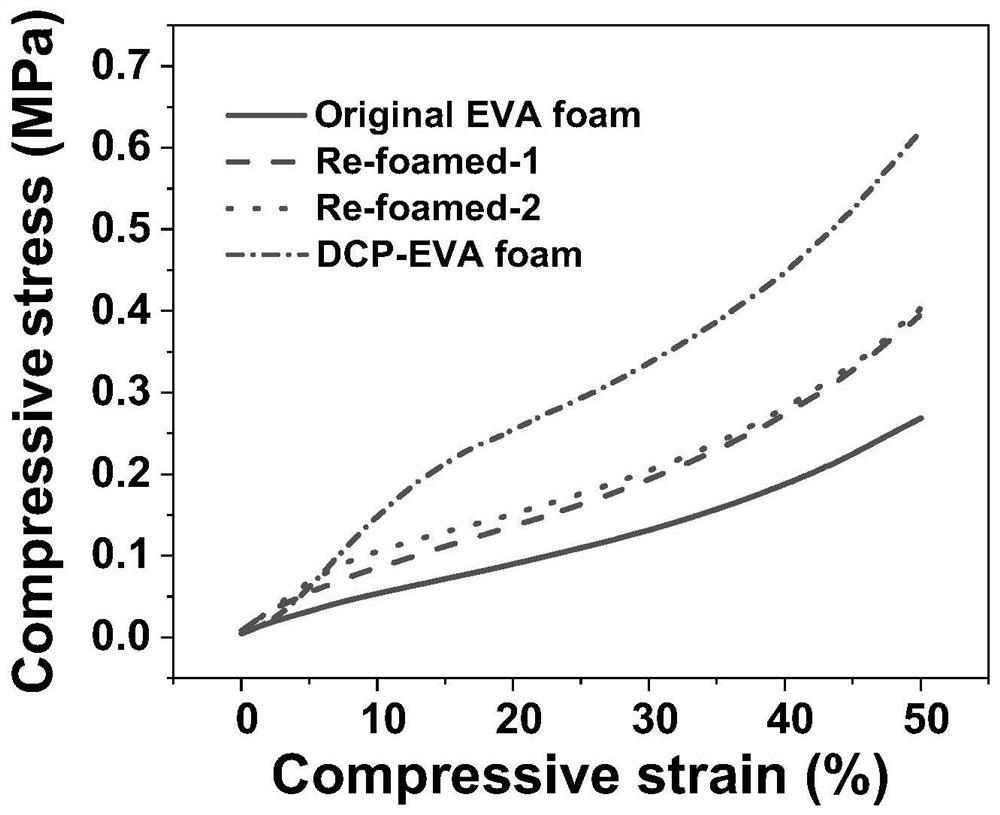

[0031] Step 5: destroy the cell structure o...

Embodiment 2

[0039] Step 1: Weigh 100 parts of ethylene-vinyl acetate copolymer, 15 parts of tripropyl phosphate, and 0.5 parts of zinc acetylacetonate by weight and pre-mix them in a beaker for 5-10 minutes;

[0040] Step 2: The ethylene-vinyl acetate copolymer premixed in step 1, the crosslinking agent and the catalyst are reactively blended in an extruder for 10 minutes, and the reaction temperature is 150° C. to obtain an EVA vitrimer material;

[0041]Step 3: get the EVA vitrimer material that obtains in the step 2 of 100 parts and carry out mechanical blending in extruder with 20 parts of heat-expandable microspheres, 2 parts of foaming aid zinc oxide and 5 parts of filler white carbon black, The blending temperature is 90°C, and the blending time is 5 minutes;

[0042] Step 4: The kneaded mixture in step 3 was molded and foamed at 150°C for 10 minutes to obtain the original EVA vitrimer foam material, which was named Original EVA foam;

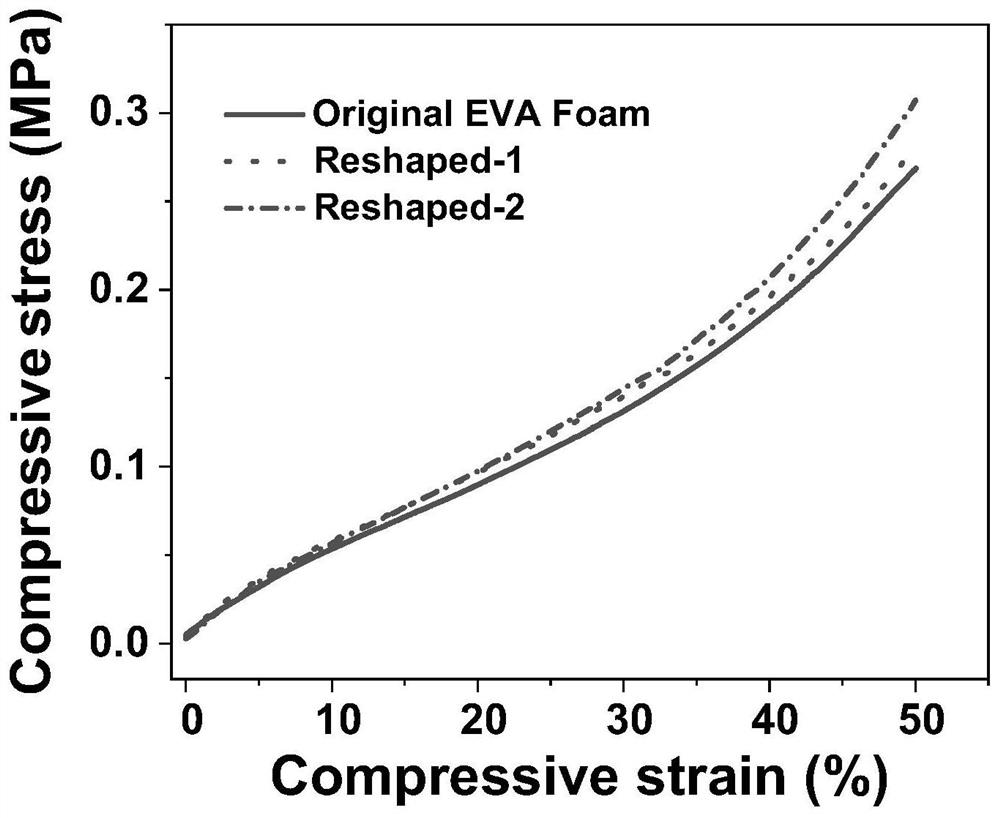

[0043] Step 5: Cut the EVA vitrimer foam mat...

Embodiment 3

[0047] Step 1: Weigh 100 parts of ethylene-vinyl acetate copolymer, 10 parts of tripropyl phosphate, and 0.1 part of zinc acetylacetonate in parts by weight, and pre-mix them in a beaker for 5-10 minutes;

[0048] Step 2: The ethylene-vinyl acetate copolymer premixed in step 1, the crosslinking agent and the catalyst are reactively blended in an extruder for 5 minutes, and the reaction temperature is 170° C. to obtain an EVA vitrimer material;

[0049] Step 3: Get 100 parts of the EVA vitrimer material obtained in step 2 and carry out mechanical co-processing with 10 parts of azodicarbonamide, 2 parts of foaming aid zinc oxide and 5 parts of filler white carbon black in an extruder Blending, the blending temperature is 80°C, and the blending time is 5min;

[0050] Step 4: The kneaded mixture in step 3 was molded and foamed at 170° C. for 5 minutes to obtain the original EVA vitrimer foam material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com