A kind of preparation method of anti-aging rubber adhesive applied to automobile tire

A technology of rubber adhesives and automobile tires, applied in the direction of natural rubber adhesives, adhesives, adhesive types, etc., can solve the problems of anti-aging agent loss, disconnection, separation of glue and cords, etc., to increase the load rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

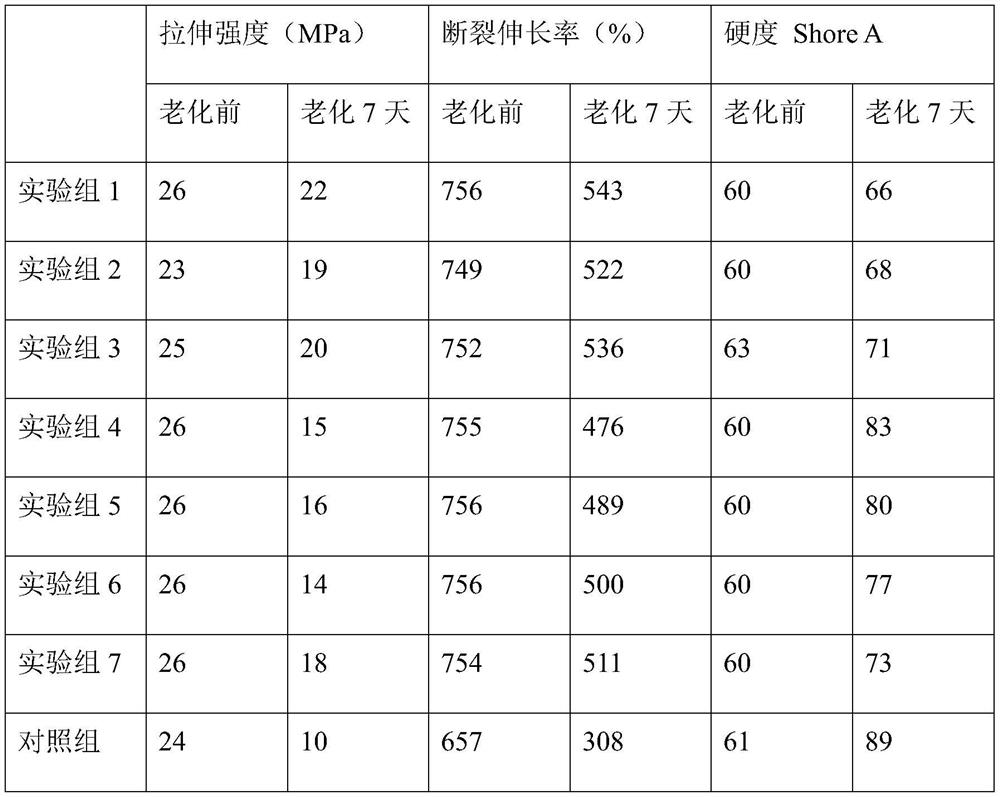

Examples

Embodiment 1

[0023] A preparation method for an aging-resistant rubber adhesive applied to automobile tires, comprising the following steps:

[0024] (1) Preparation of slow-release carrier: select hollow natural fibers to rinse first to remove surface impurities, and select plant fibers for the hollow natural fibers, including but not limited to cotton fibers, flax fibers, jute fibers, coconut shell fibers, bamboo fibers, ramie Fiber, loofah fiber or any several, select bamboo fiber in the present embodiment. The hollow cavity inside the plant fiber can hold the anti-aging agent and play a slow-release role. In addition, the plant fiber has high toughness, and has a high water absorption and swelling property to form a three-dimensional fiber network structure, which can improve the bonding of the adhesive. strength and stability. After it is dried in the air, it is vacuumized, so that the hollow natural fiber is placed in a low-pressure environment with a pressure of 20% of atmospheric ...

Embodiment 2

[0031] A preparation method for an aging-resistant rubber adhesive applied to automobile tires, comprising the following steps:

[0032](1) Preparation of slow-release carrier: select hollow natural fibers to rinse first to remove surface impurities, and select plant fibers for the hollow natural fibers, including but not limited to cotton fibers, flax fibers, jute fibers, coconut shell fibers, bamboo fibers, ramie Fiber, loofah fiber or any several, select jute fiber in the present embodiment. The hollow cavity inside the plant fiber can hold the anti-aging agent and play a slow-release role. In addition, the plant fiber has high toughness, and has a high water absorption and swelling property to form a three-dimensional fiber network structure, which can improve the bonding of the adhesive. strength and stability. After it is dried, it is subjected to vacuum treatment, so that the hollow natural fiber is placed in a low-pressure environment with a pressure of 30% of atmosph...

Embodiment 3

[0039] A preparation method for an aging-resistant rubber adhesive applied to automobile tires, comprising the following steps:

[0040] (1) Preparation of slow-release carrier: select hollow natural fibers to rinse first to remove surface impurities, and select plant fibers for the hollow natural fibers, including but not limited to cotton fibers, flax fibers, jute fibers, coconut shell fibers, bamboo fibers, ramie Fiber, loofah fiber or any several, in the present embodiment, select loofah fiber for use. The hollow cavity inside the plant fiber can hold the anti-aging agent and play a slow-release role. In addition, the plant fiber has high toughness, and has a high water absorption and swelling property to form a three-dimensional fiber network structure, which can improve the bonding of the adhesive. strength and stability. After it is dried, it is subjected to vacuum treatment, so that the hollow natural fiber is placed in a low-pressure environment with a pressure of 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com