Preparation method of cotton fabric with mosquito repelling function

A cotton fabric and functional technology, which is applied in the field of preparation of cotton fabrics with mosquito repellent function, can solve the problems of poisoning, mosquito release, and inability to keep repelling and killing mosquitoes for a long time, so as to reduce usage, reduce pollution, and have strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

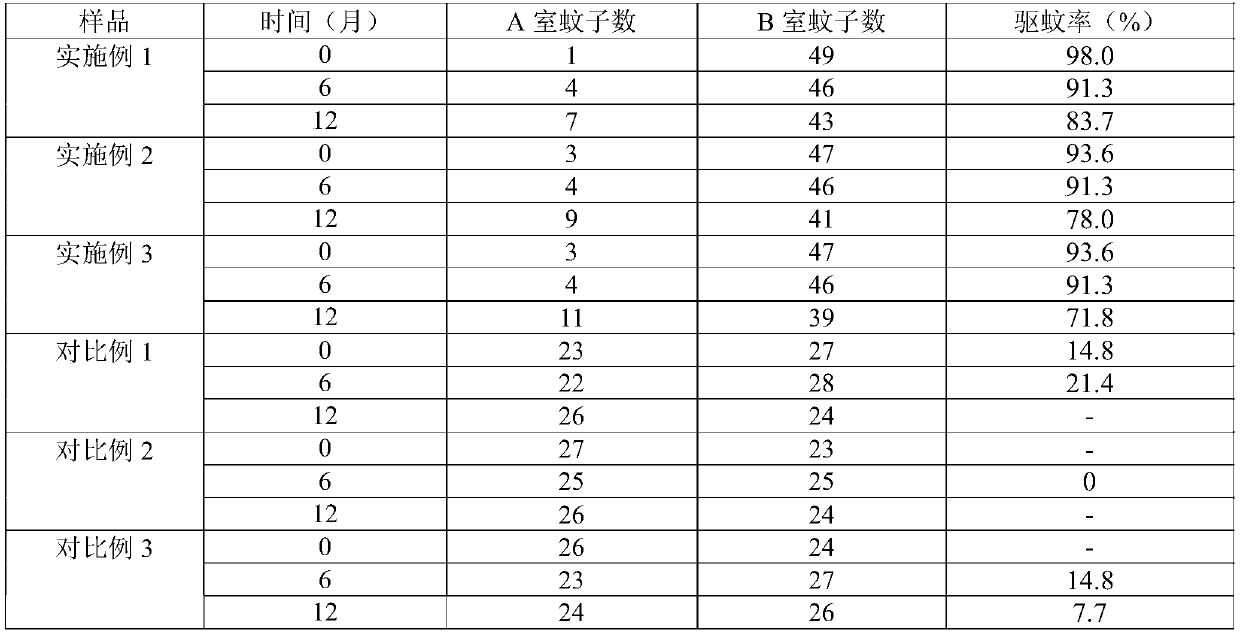

Embodiment 1

[0024] A preparation method of cotton fabric with mosquito repellent function, comprising the steps of:

[0025] 1. Put 1g of cotton fabric into 45mL of 40g / L pectinase solution with a specific activity of 100U / g, treat it at 50°C for 25min, and then treat it with plasma. The conditions are: the gas is nitrogen, the processing power is 200W, and the pressure is 55Pa, the processing time is 25min.

[0026] 2. Add 2g of glucose, 4g of bean cake powder and 1g of calcium carbonate into 1000mL of water, insert Streptomyces after sterilization, stir at 120r / min at 28°C for 0.9vvm aerated fermentation for 5 days, filter the fermentation broth and take the filter cake as Streptomyces Fermented extract.

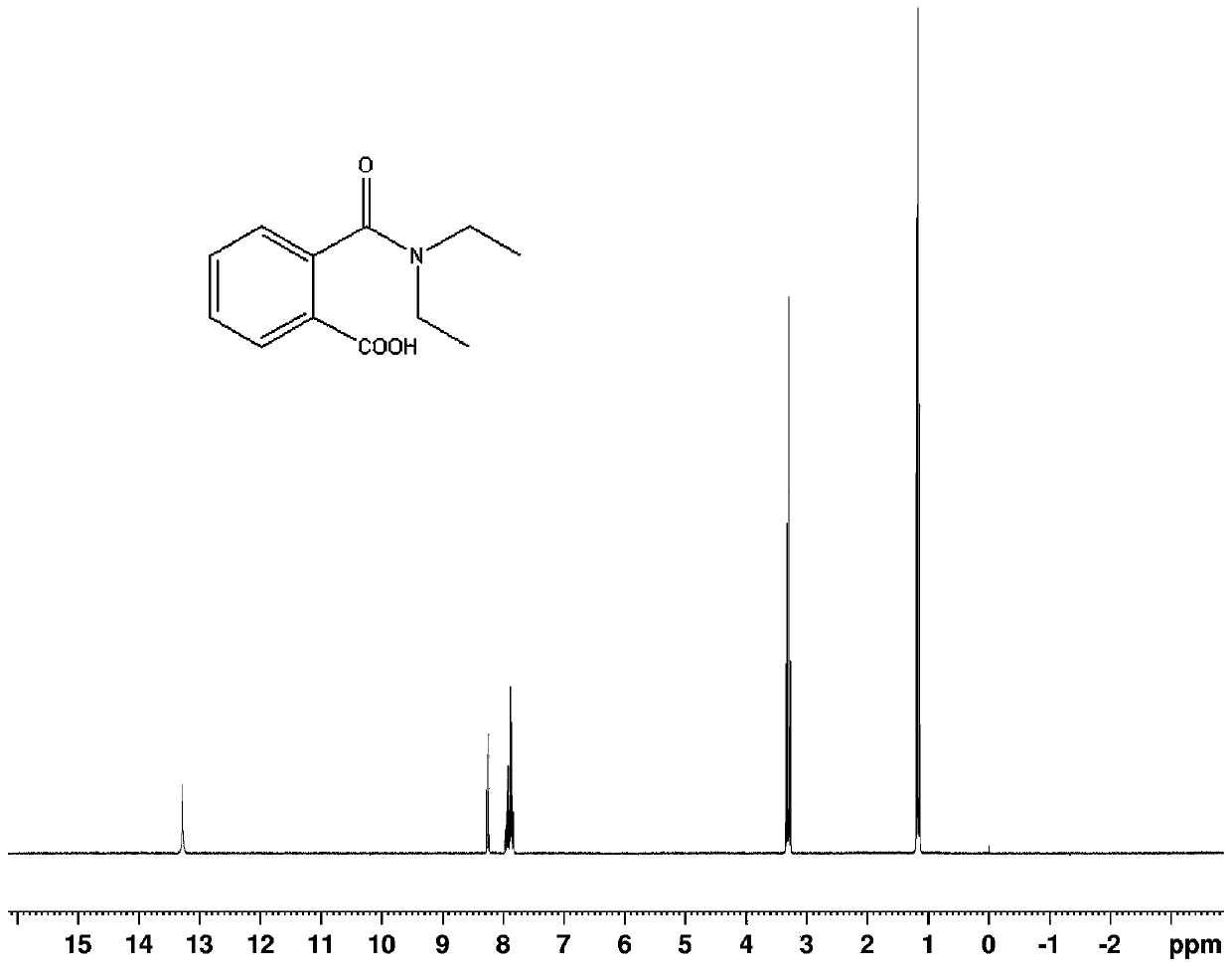

[0027] 3. Immerse the cotton fabric treated in step 1 in 50 mL of 1-butyl-3-methylimidazole hexafluoride containing 100 g / L phthalic anhydride, 80 g / L diethylamine and 100 g / L Streptomyces fermentation extract Soak in phosphate liquid for 18 hours at 30°C.

[0028] 4. Wash the cott...

Embodiment 2

[0031] A preparation method of cotton fabric with mosquito repellent function, comprising the steps of:

[0032] 1. Put 1g of cotton fabric into 40mL of 20g / L pectinase solution with a specific activity of 50U / g, treat it at 30°C for 20 minutes, and then treat it with plasma. The conditions are: the gas is nitrogen, the processing power is 100W, and the pressure is 50Pa, the processing time is 20min.

[0033] 2. Add 1.5g of glucose, 3g of bean cake powder and 0.6g of calcium carbonate to 1000mL of water, insert streptomyces after sterilization, stir at 100r / min at 25°C for 4 days with aeration and fermentation at 0.8vvm, filter the fermentation broth and take the filter cake. Streptomyces Ferment Extract.

[0034] 3. Immerse the cotton fabric treated in step 1 in 40mL of 1-butyl-3-methylimidazole hexafluoride containing 80g / L phthalic anhydride, 50g / L diethylamine and 60g / L Streptomyces fermentation extract Soak in phosphate solution for 12 hours at 25°C.

[0035] 4. Wash t...

Embodiment 3

[0037] A preparation method of cotton fabric with mosquito repellent function, comprising the steps of:

[0038] 1. Put 1g of cotton fabric into 50mL of 60g / L pectinase solution with a specific activity of 150U / g, treat it at 60°C for 30 minutes, and then treat it with plasma. The conditions are: the gas is nitrogen, the processing power is 250W, and the pressure is 60Pa, the processing time is 30min.

[0039] 2. Add 3g of glucose, 5g of bean cake powder and 1.2g of calcium carbonate into 1000mL of water, insert Streptomyces after sterilization, stir at 150r / min at 30°C for 1vvm aeration and ferment for 6 days, filter the fermentation broth and take the filter cake as Streptomyces Fermented extract.

[0040] 3. Soak the cotton fabric treated in step 1 in 60mL of 1-ethyl-3-methylimidazolium tetrafluoroethylene containing 180g / L phthalic anhydride, 100g / L diethylamine and 200g / L Streptomyces fermentation extract Soak in borate liquid for 24 hours at 37°C.

[0041] 4. Wash the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com