Construction process for alternative waterproof casing pipe

A construction technology and waterproof casing technology, applied in the direction of pipes, damage protection, pipeline protection, etc., can solve the problems that linoleum and asbestos cement are not suitable for filling, difficult to solve, and easy to confuse, so as to simplify the later maintenance and management work, The effect of improving construction quality and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

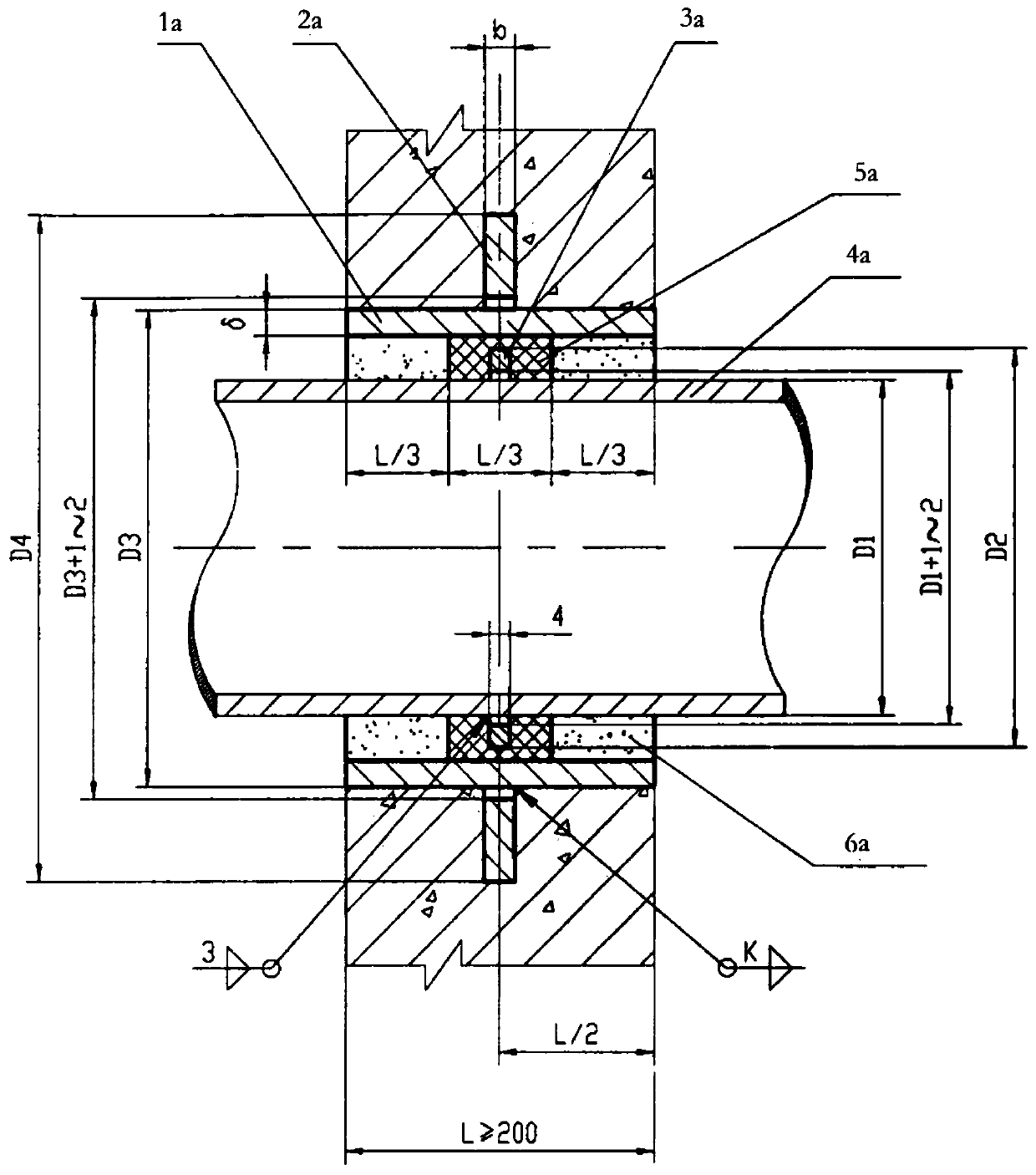

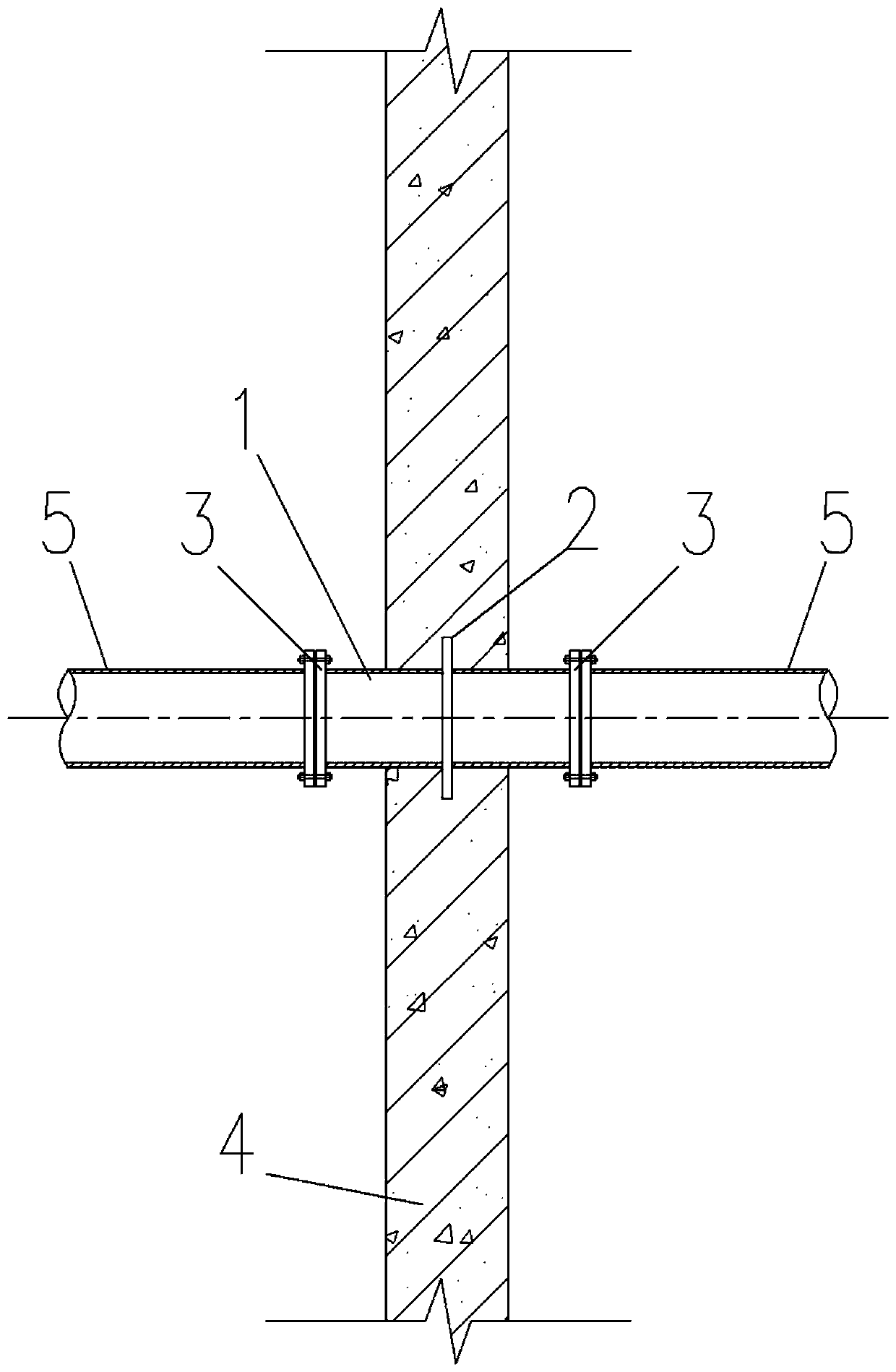

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0026] according to figure 2 , the present invention provides a construction technique for replacing the waterproof casing, comprising the following steps:

[0027] (1) Cut the material according to the pipe diameter and pipe section length determined by the design. The pipe section can be made of metal pipe or PVC pipe. Install the water stop ring 2 in the middle of the pipe section 1, and install the connecting joint 3 at both ends of the pipe section. The connection method of the connecting joint It is a detachable fixed connection; the connection joint can be a flange connection joint, a socket connection joint, a threaded connection joint, a clamp type connection joint or a compression type connection joint, and the water stop ring 2 is made of the same material as the pipe section 1, The plastic hydrofoil ring is glued and fixed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com