A non-contact non-destructive testing method and device for thermal barrier coating insulation temperature

A technology for thermal barrier coatings and non-destructive testing, which is applied in the directions of measuring devices, radiation pyrometry, and thermal development of materials, etc. It can solve problems such as difficulty in characterizing the thermal insulation effect of coatings, uncertainty, and test data delays. The effect of wide application range, simple operation and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

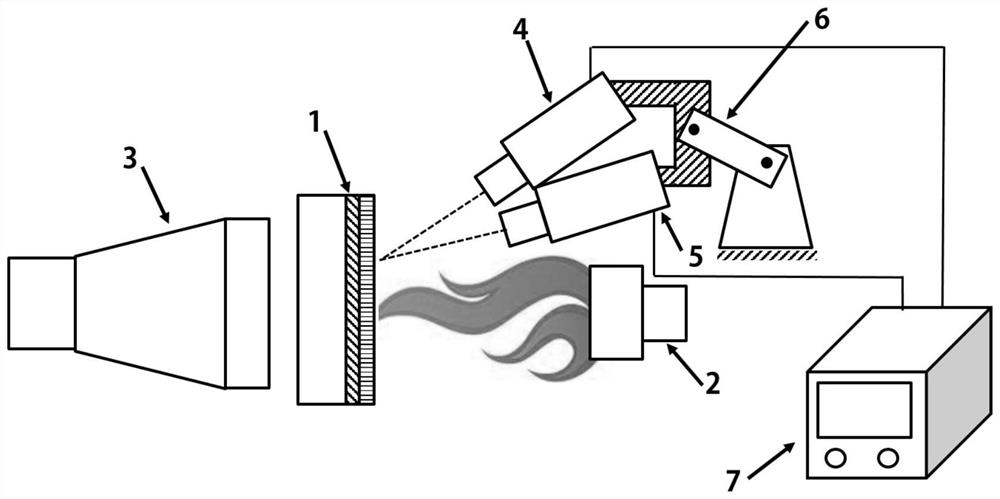

[0047] Such as figure 1 As shown, the DD6 nickel-based single crystal superalloy with a diameter of 25.4 mm and a thickness of 2.5 mm was used as the substrate, and a NiCoCrAlY metal bonding layer with a thickness of 120 μm was prepared on the surface of the superalloy substrate by low-pressure plasma spraying technology. Technology Prepare an 8YSZ ceramic thermal insulation top layer with a thickness of 250 μm on the surface of the metal bonding layer, and use the above-mentioned superalloy sheet with a thermal barrier coating as the thermal barrier coating sample 1 of the superalloy substrate to be tested.

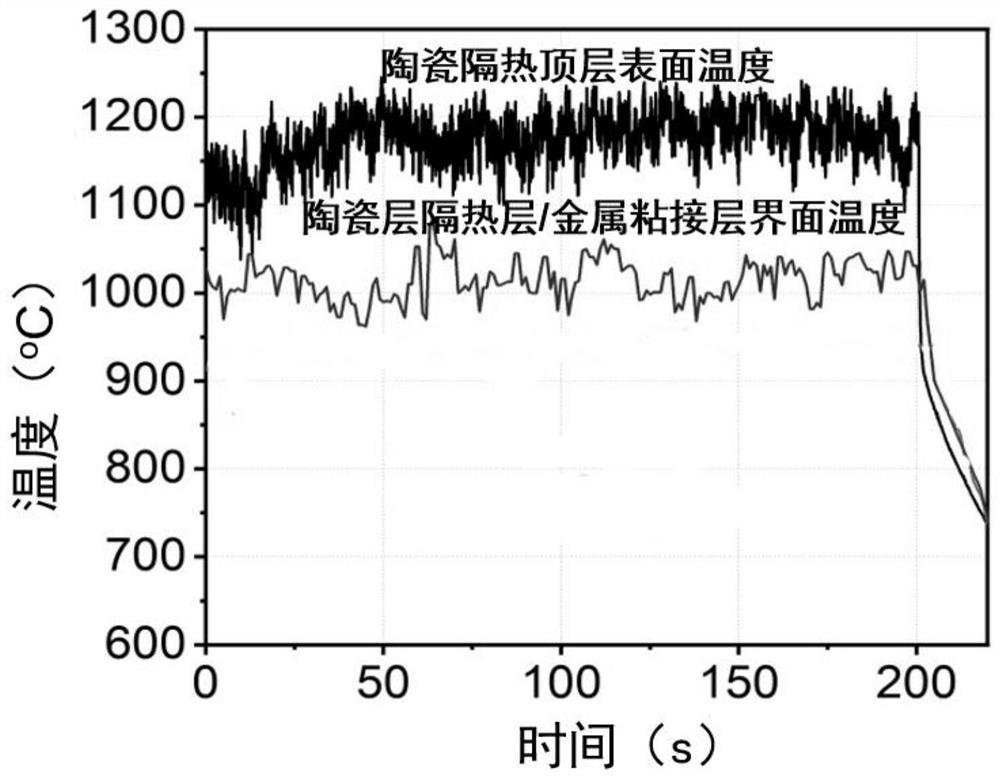

[0048] The oxyacetylene flame gun is used as the surface heating device 2 of the thermal barrier coating ceramic heat insulation top layer, and the oxyacetylene flame is used to heat the surface of the thermal barrier coating ceramic heat insulation layer to simulate the effect of high temperature gas on the blade surface thermal barrier coating in the actual service envi...

Embodiment 2

[0051] Firstly, using the equiaxed nickel-based superalloy with a diameter of 25.4 mm and a thickness of 2.5 mm as the substrate, a NiCoCrAlY metal bonding layer with a thickness of 120 μm was prepared on the surface of the superalloy substrate by low-pressure plasma spraying technology, and an electron beam physical vapor phase The 8YSZ ceramic thermal insulation top layer with a thickness of 200 μm was prepared on the surface of the metal bonding layer by deposition method, and the above-mentioned superalloy sheet with thermal barrier coating was used as the superalloy component with thermal barrier coating.

[0052] Use an oxyacetylene flame gun as the surface heating device 2 of the ceramic heat insulation top layer of the thermal barrier coating, use a compressed air gun to cool the surface of the superalloy substrate with a thermal barrier coating, and obtain a theoretical heat insulation temperature of 200°C by adjusting the cooling air flow rate. conditions for experime...

Embodiment 3

[0055] Firstly, using the directionally solidified nickel-based superalloy with a diameter of 25.4 mm and a thickness of 2.5 mm as the substrate, a NiCoCrAlY metal bonding layer with a thickness of 150 μm was prepared on the surface of the superalloy substrate by low-pressure plasma spraying technology. 8YSZ ceramic thermal insulation top layer with a thickness of 500 μm was prepared on the surface of the metal bonding layer, and the above-mentioned superalloy sheet with thermal barrier coating was used as a superalloy component with thermal barrier coating.

[0056] The oxyacetylene flame gun is used as the surface heating device of the thermal barrier coating ceramic heat insulation top layer, and the oxyacetylene flame is used to heat the surface of the thermal barrier coating ceramic heat insulation layer to simulate the effect of high temperature gas on the blade surface thermal barrier coating in the actual service environment. Thermal shock: using a compressed air gun as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com