3D model construction method and preparation method for aortic valve disease

An aortic valve and construction method technology, applied in the field of 3D printing, can solve the problems of misleading preoperative evaluation of the model, low accuracy of the aortic valve leaflet model, etc., to improve the surgical effect, high accuracy, and ensure production accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

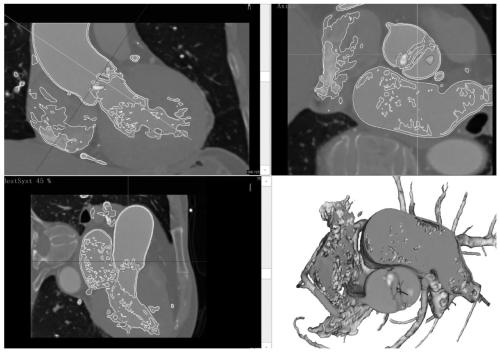

Image

Examples

Embodiment 1

[0062] Disclosed in this embodiment is a method for building a 3D model for aortic valve disease, which is implemented in the Mimics software using the following steps:

[0063] (1) Use medical imaging equipment to collect data on aortic angiography of patients with aortic valve disease (aortic valve stenosis, aortic valve insufficiency, aortic valve stenosis), mainly collecting the patient's aortic root and part of the ascending aorta , coronary artery and left atrium, and generate CT (DICOM) files including systole and diastole.

[0064] (2) Import the DICOM file into Mimics software, and generate a .mcs file to save

[0065] (3) Split data:

[0066] Step1, in the Pseudo colors command, according to the different chromatograms displayed by different tissues, observe the structure and boundary of different tissues, calcification, leaflet shape and degree of calcification;

[0067] Step2, CT image playback selects the phase data with the largest leaflet opening, and adjusts ...

Embodiment 2

[0076] This embodiment discloses a method for preparing a 3D model for aortic valve disease. On the basis of Embodiment 1, it also includes the following steps:

[0077] Step 1: Use any of the above-mentioned 3D model construction methods for aortic valve disease to obtain a 3D model for aortic valve disease, and export the model as an STL format file;

[0078] Step 2: Import the 3D model into the OBJET slicing software for printing. During the slicing process, the height of the model should be as low as possible to reduce the printing time. After removing the large support on the surface of the model with tools, place the printed 3D model in alkaline Shake and clean in the solution. After cleaning, take the model out of the solution and rinse the surface residue. Use a water gun tool to rinse the residual support material and alkaline solution on the surface;

[0079] Step 3: Put the 3D model obtained in step 2 into the drying box and keep the blast mode for drying, take out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com