Electromagnetic driving vacuum die-casting machine

A technology of vacuum die-casting and electromagnetic drive, which is applied in the field of precision parts forming, and can solve problems such as the start-up time and long distance of the injection rod, and achieve the effect of shortening start-up time, reducing maintenance time and improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

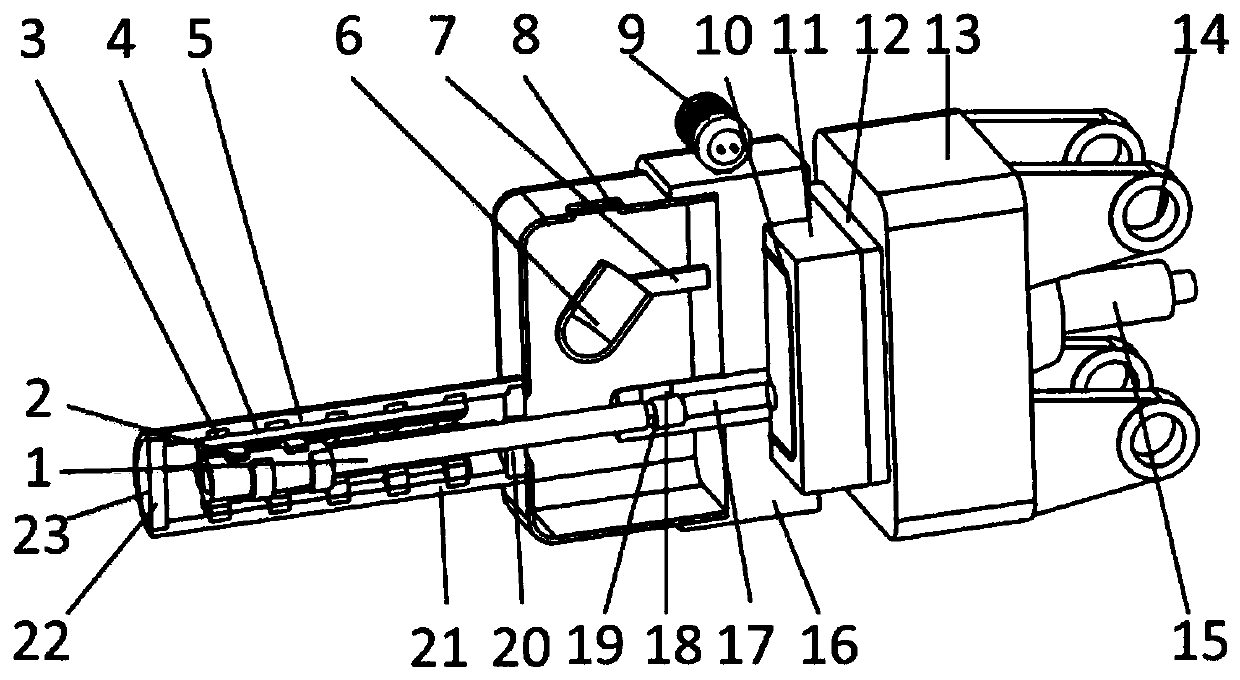

[0030] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

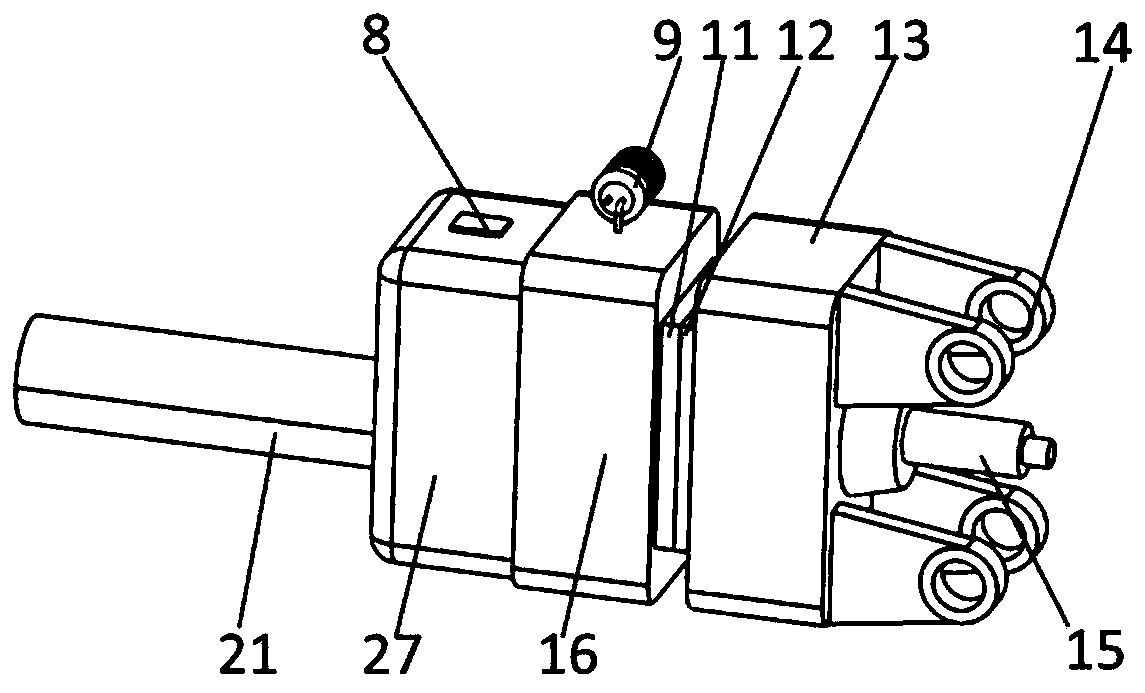

[0031] Solenoid-driven vacuum die-casting machines, such as figure 1 and figure 2 As shown, it includes a drive assembly, a fixed mold assembly, a movable mold assembly, an executive assembly, a sealing ring 10 and a rectangular shell 27 .

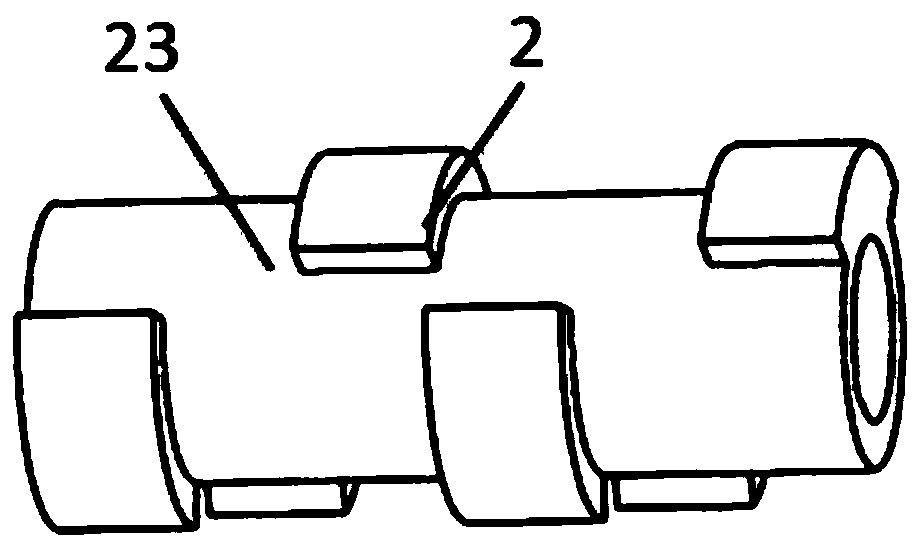

[0032] drive components such as figure 2As shown, it includes a stator assembly and a mover assembly. The stator assembly includes a stator ferromagnetic ring 3 , a stator winding 4 , a stator magnetic isolation ring 5 , a heat shield 20 , a cylindrical shell 21 and a rear cover 22 . The cylindrical shell 21 is welded by the same two semicircles, the back cover 22 is located at the first end inside the cylindrical shell 21, the heat shield 20 is located at the second end inside the cylindrical shell 21, and the stator ferroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com