Preparation method of insulation composite material rail clamping plate

A technology of insulating composite materials and track splints, applied in the direction of coating, etc., can solve the problems of short service life, poor weighing effect, poor insulation of track splints, etc., to avoid short circuit of track circuit, facilitate transportation and installation, and reduce maintenance The effect of the replacement workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

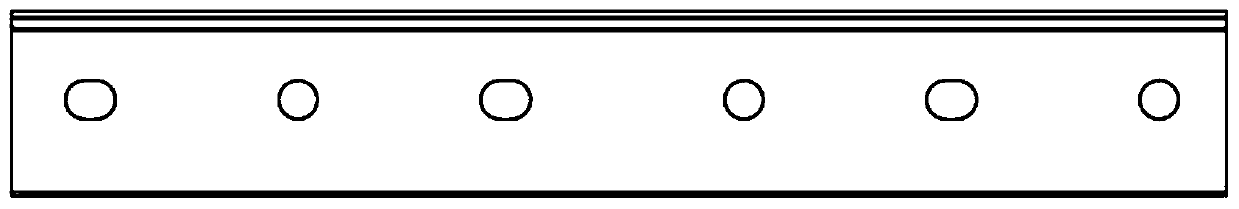

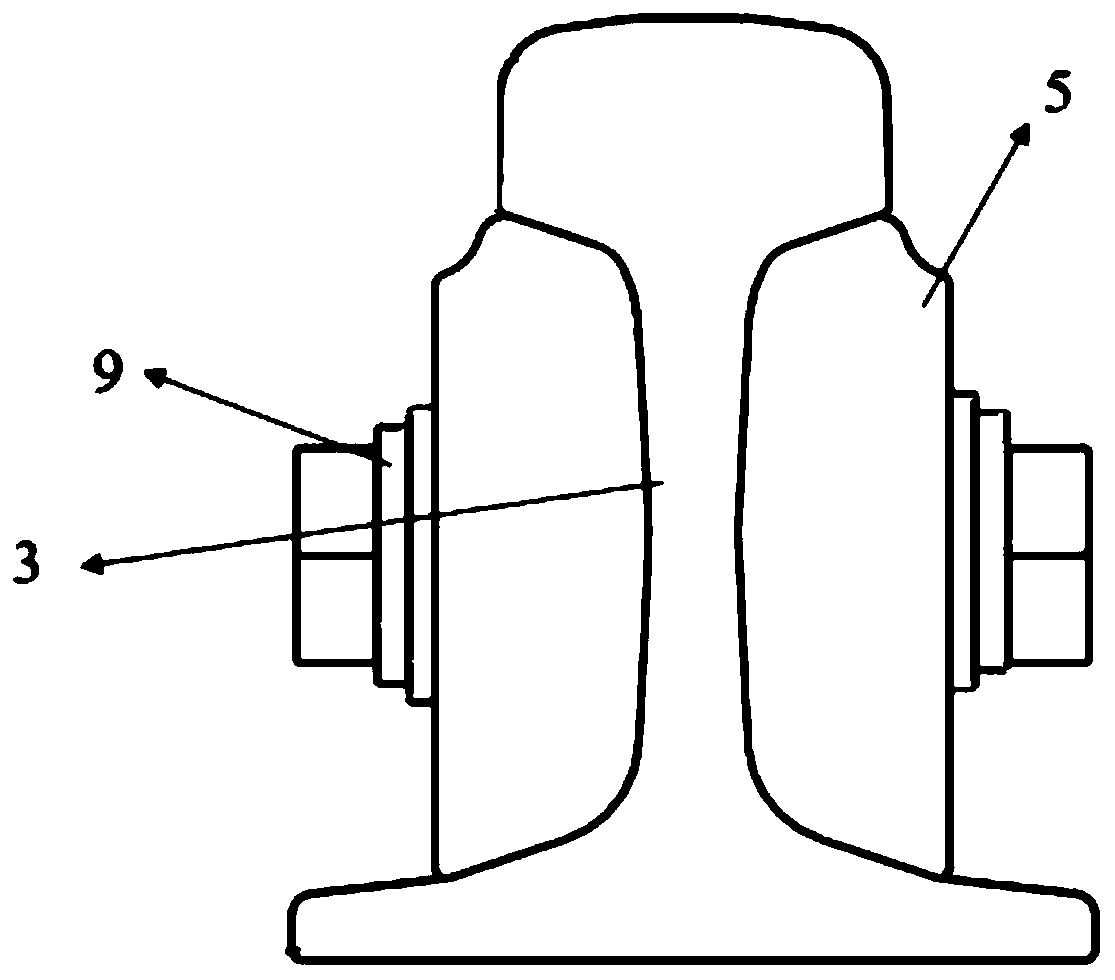

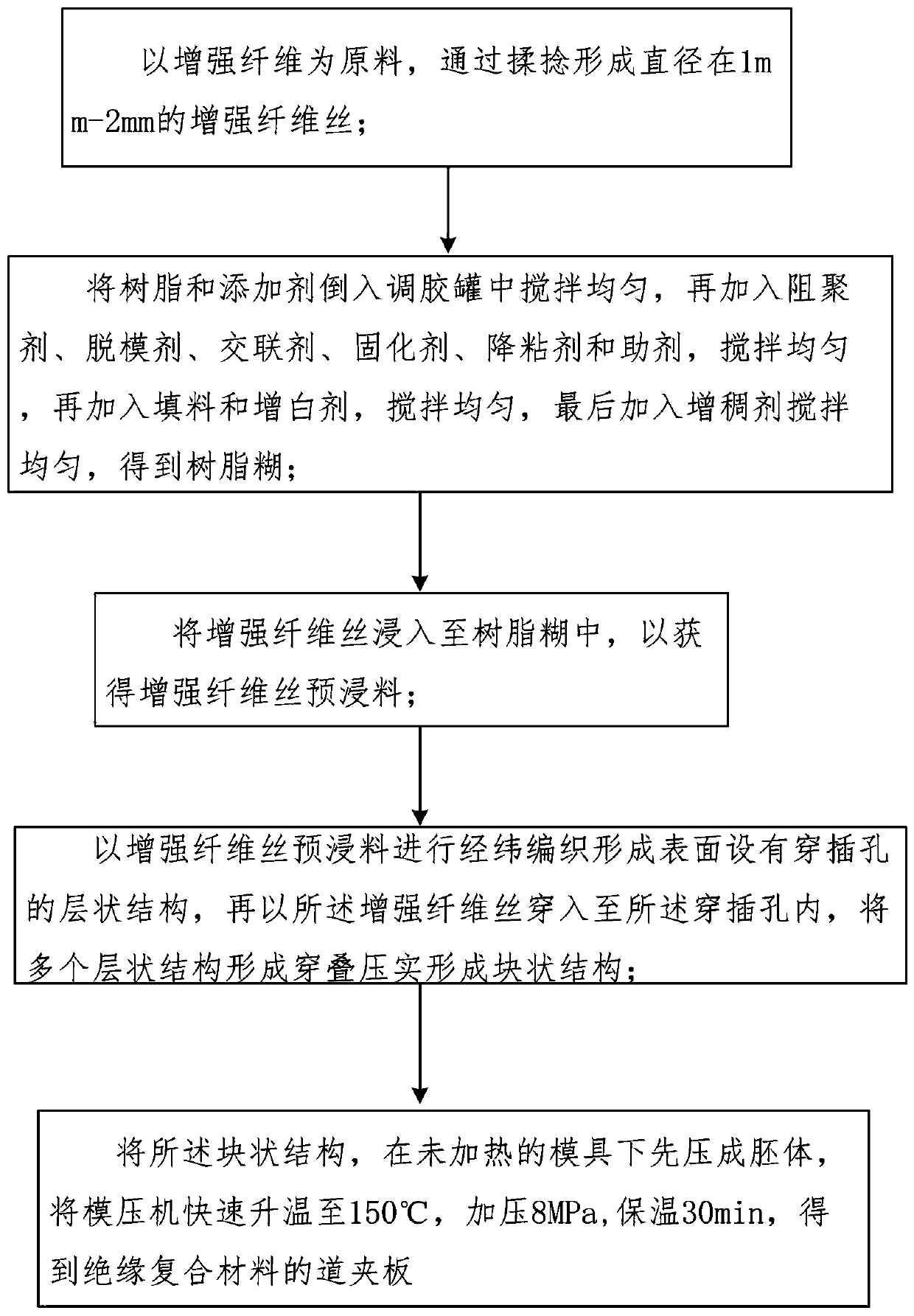

[0025] see figure 1 , and combined with figure 2 and image 3 Shown, the preparation method of a kind of insulating composite material splint of the present invention comprises the following steps:

[0026] Step S1, using reinforced fibers as raw materials, forming reinforced fiber filaments with a diameter of 1mm-2mm by kneading, and the raw materials of reinforced fiber filaments are one or more of glass fibers, basalt fibers, carbon fibers, or mixed fibers;

[0027] Step S2, pour the resin and additives into the glue mixing tank and stir evenly, then add polymerization inhibitor, mold release agent, crosslinking agent, curing agent, viscosity reducer and auxiliary a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com