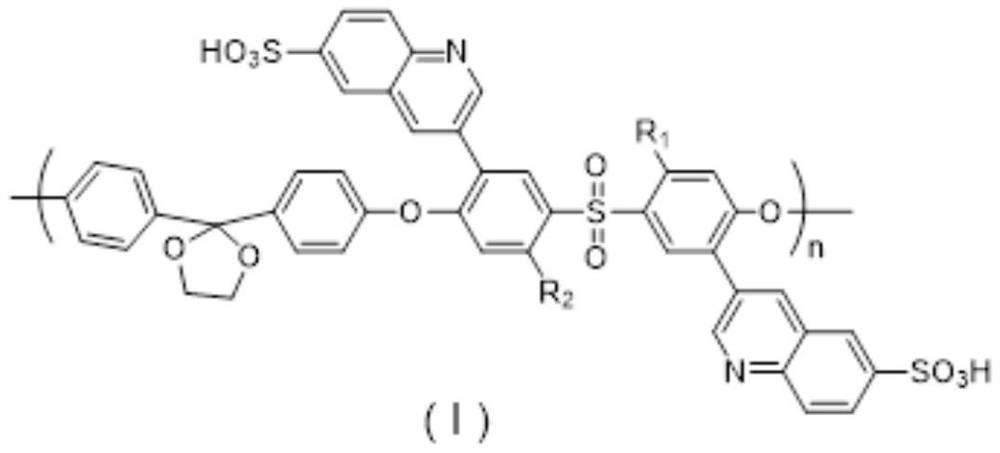

A kind of sulfonated polyarylether sulfone and its preparation method

A technology of sulfonated polyarylether sulfone and polyarylether sulfone, which is applied in the field of sulfonated polyarylether sulfone and its preparation, and achieves the effects of simple preparation method, good water absorption and chlorine resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Synthesis of sulfonated polyarylethersulfone (IA)

[0022]

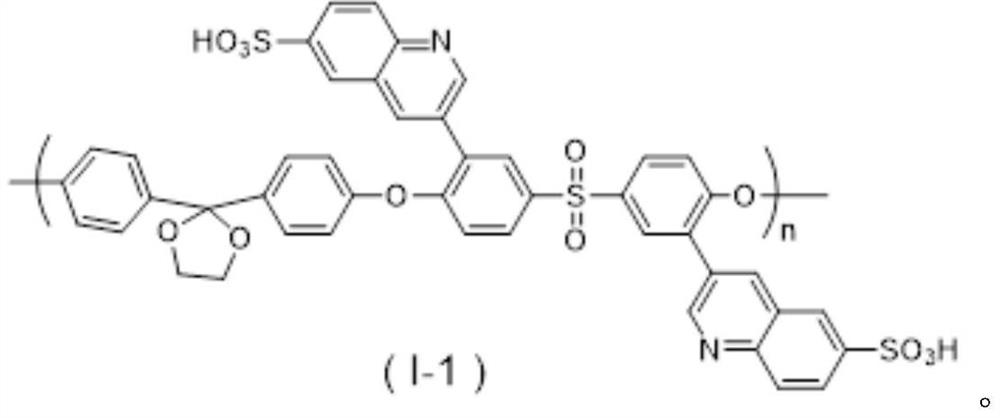

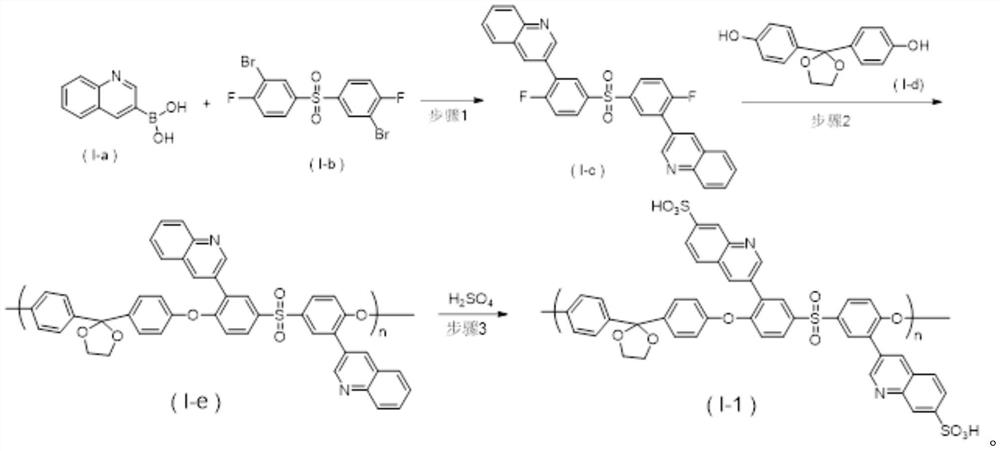

[0023] Step 1: Synthesis of 3,3'-(sulfonylbis(6-fluoro-3,1-phenylene))bisquinoline (I-c)

[0024]

[0025] 4,4'-sulfonylbis(2-bromo-1-fluorobenzene) (8.24 g, 20 mmol) was dissolved in 100 mL of tetrahydrofuran, 0.2 g of tetrakis(triphenylphosphine) palladium was added, and quinoline-3-boronic acid was added (7.26 g, 42 mmol), heated to reflux for 12 hours under nitrogen protection. After the reaction was completed, it was brought to room temperature, 100 mL of water was added, stirring was continued for 1 hour, and filtered to obtain crude 3,3'-(sulfonylbis(6-fluoro-3,1-phenylene))bisquinoline. After recrystallization from toluene, the final product, 3,3'-(sulfonylbis(6-fluoro-3,1-phenylene))bisquinoline crude product, was 8.63 g, with a yield of 85%.

[0026] MS m / z: 509.2[M+H]+

[0027] Step 2: Synthesis of polyarylethersulfone (I-e)

[0028]

[0029] To the reaction flask was added 3...

experiment example 1

[0033] Experimental Example 1: Water Absorption Test

[0034] Under the test conditions of 25℃ and 80℃, a certain size of sulfonated polyarylethersulfone (I-B) and Nafion blank membrane were soaked in deionized water for 24h, and then the mass Mw of the soaked homogeneous membrane was weighed with an analytical balance. . Put the soaked sample into a vacuum drying oven, dry at 75°C for 24 hours, and weigh the mass Md of the dry film after it is completely dried. The water absorption formula is (Mw-Md) / Md*100%. The experimental results are shown in Table 1.

experiment example 2

[0035] Experimental example 2: Test of ion exchange capacity

[0036] Weigh the fully dried sulfonated polyaryl ether sulfone (I-B) and Nafion blank membrane (weight as M), use N-methylpyrrolidone as a solvent, use 10 mL of N-methylpyrrolidone to dissolve the above, and add 10 mL of dehydration after fully dissolving. Ionized water, using methyl red as an indicator, was titrated with a calibrated NaOH solution (concentration denoted as C1) (the volume consumed by NaOH was denoted as V1), tested 3 times, and used formula (2) to calculate the ion exchange capacity, the formula is IEC=V1*C1 / M. The experimental results are shown in Table 1.

[0037] Table 1

[0038]

[0039] It can be seen from the above results that the water absorption and ion exchange capacity of the sulfonated polyaryl ether sulfone of the present invention are obviously better than those of Nafion, and have great commercial application potential.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com