Dense thin separator for reducing nitrogen oxide emission

A technology of thick-thin separator and nitrogen oxides, which is applied in the field of thick-thin separator, can solve the problems of insufficient separation effect of inertial separator, unsuitable high wind speed of pulverized coal inlet, and influence on flow field of inertial separator, so as to reduce fuel consumption Effects of NOx and thermal NOx generation, increased flow, and high inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

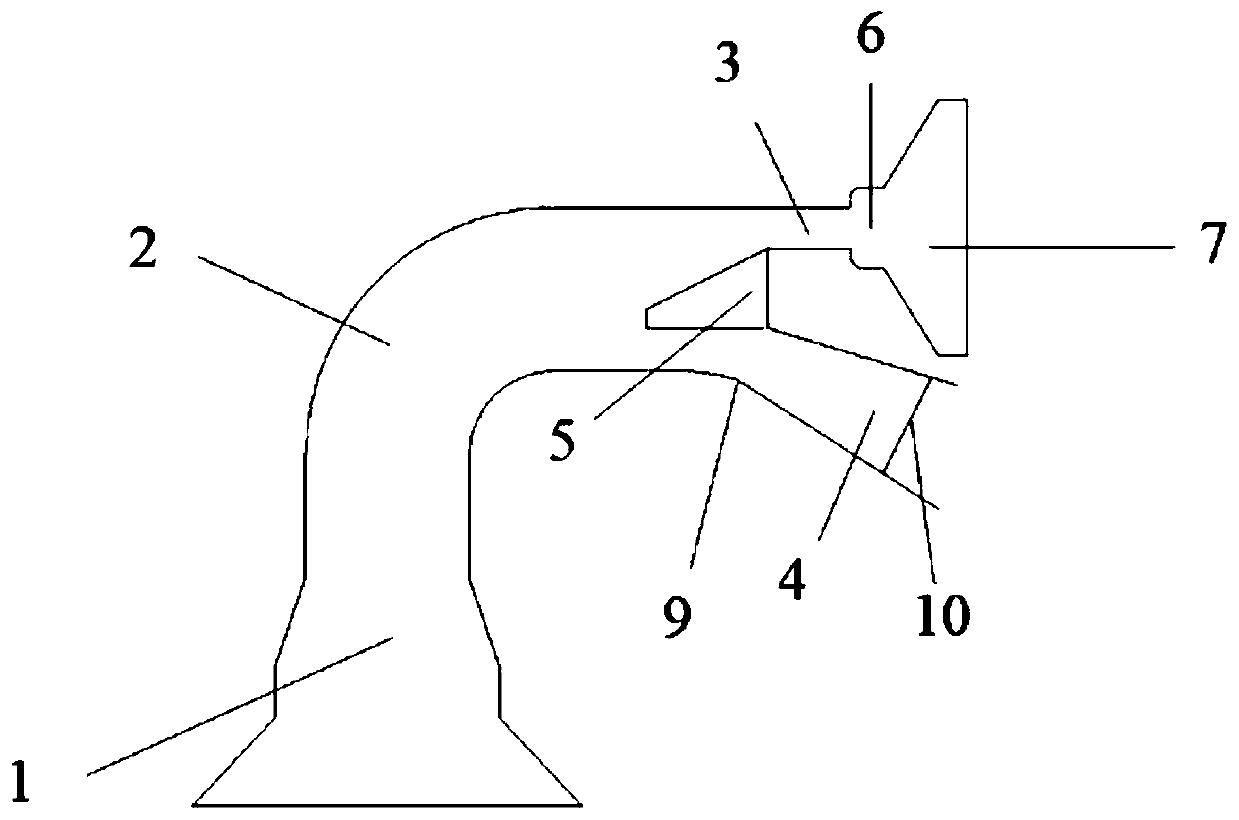

[0035] like figure 1 As shown, a concentration separator for reducing nitrogen oxide emission, the concentration separator includes a pulverized coal inlet pipe 1, a pulverized coal main pipe 2 and a pulverized coal outlet pipe connected in sequence along the flow direction of the pulverized coal gas flow, and the pulverized coal inlet pipe The inner diameter of 1 decreases in a stepwise manner along the flow direction of the pulverized coal gas flow. The pulverized coal main pipe 2 is of an elbow structure. The pulverized coal outlet pipe includes a dense phase pulverized coal outlet pipe 3 and a light phase pulverized coal outlet pipe 4. A deflector 5 is provided, and the deflector 5 is located between the dense-phase pulverized coal outlet pipe 3 and the light-phase pulverized coal outlet pipe 4. The radial length is smaller than the radial length near the side of the pulverized coal outlet pipe, the inner diameter of the dense phase pulverized coal outlet pipe 3 gradually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com