Preparation method of in-situ electrical TEM sample

A sample, in-situ technology, applied in the field of TEM sample preparation, can solve the problem of inability to directly observe the continuous change of the microstructure of the material, and achieve the effect of high universality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

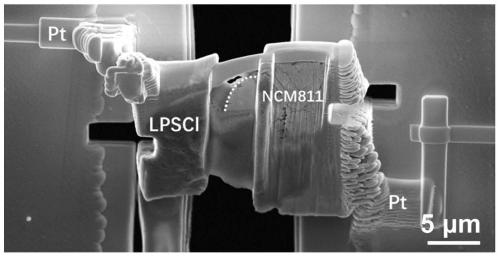

[0023] Preparation of NCM811 / LPSCl in situ electrical TEM samples

[0024] (1) Connect the solid-state electrolyte and the electrode material using the magnetron sputtering method.

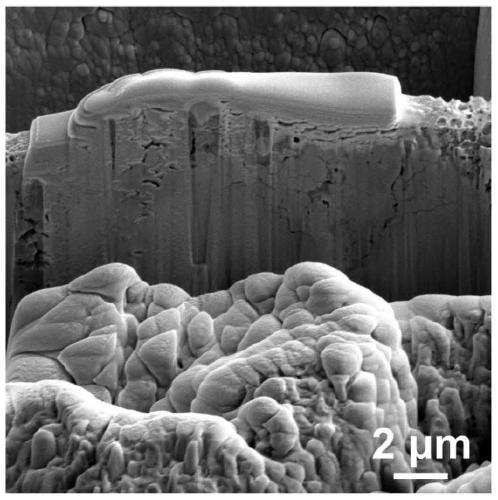

[0025] Put the electrode material NCM811 and the solid electrolyte target LPSCl into the magnetron sputtering furnace, sputter for about 50 minutes under the condition of a pressure of 2Pa and a power of 100W, and cover the electrode material with a solid electrolyte of 800nm to obtain an electrode / electrolyte Material.

[0026] (2) Put the electrode / electrolyte material prepared in step (1) into a focused ion beam electron microscope for processing.

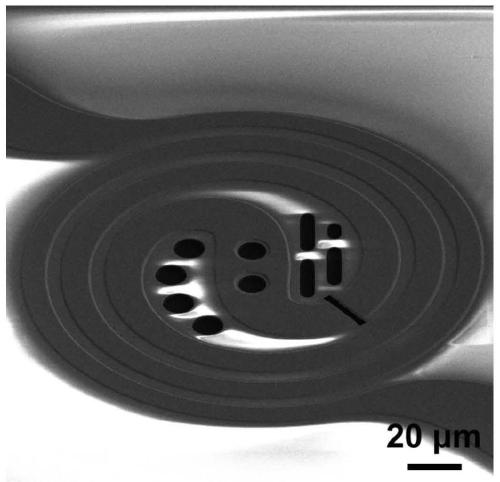

[0027] Adjust the height of the sample area to the height of the confocal, extend the Pt needle after preheating, deposit a Pt protective layer with a thickness of 800nm with an ion beam of 30kV, 0.8nA, and control the beam current of FIB (Focused Ion Beam abbreviation, focused ion beam) at 26pA / um 2 . Choose 30kV, 6.5nA FIB beam to etch bot...

Embodiment 2

[0029] Preparation of Si / LiFePO 4 / LAGP in situ electrical TEM samples

[0030] (1) Connect the solid-state electrolyte and the electrode material using the magnetron sputtering method.

[0031] Si substrate and LiFePO 4 Put it into a magnetron sputtering furnace, and sputter the ceramic composite electrolyte (LAGP) for 20 minutes under the conditions of a pressure of 2Pa and a power of 60W to obtain a 100nm LAGP. Thus an electrode / electrolyte material is obtained.

[0032](2) Put the electrode / electrolyte material prepared in step (1) into a focused ion beam electron microscope for processing.

[0033] Adjust the height of the sample area to the height of the confocal, extend the Pt needle after preheating, deposit a Pt protective layer with a thickness of 1um with an ion beam of 30kV, 0.8nA, and control the beam current of the FIB at 26pA / um 2 . Choose 30kV, 6.5nA FIB beam to etch both sides of the TEM sheet, the termination position is the edge of the Pt protective lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com