Rock sample block stress field simulation device

一种岩石试样、模拟装置的技术,应用在使用施加稳定的张力/压力测试材料强度等方向,能够解决实施成本高、液压泵站系统复杂等问题,达到便于装配、经济实用、优化结构工艺性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

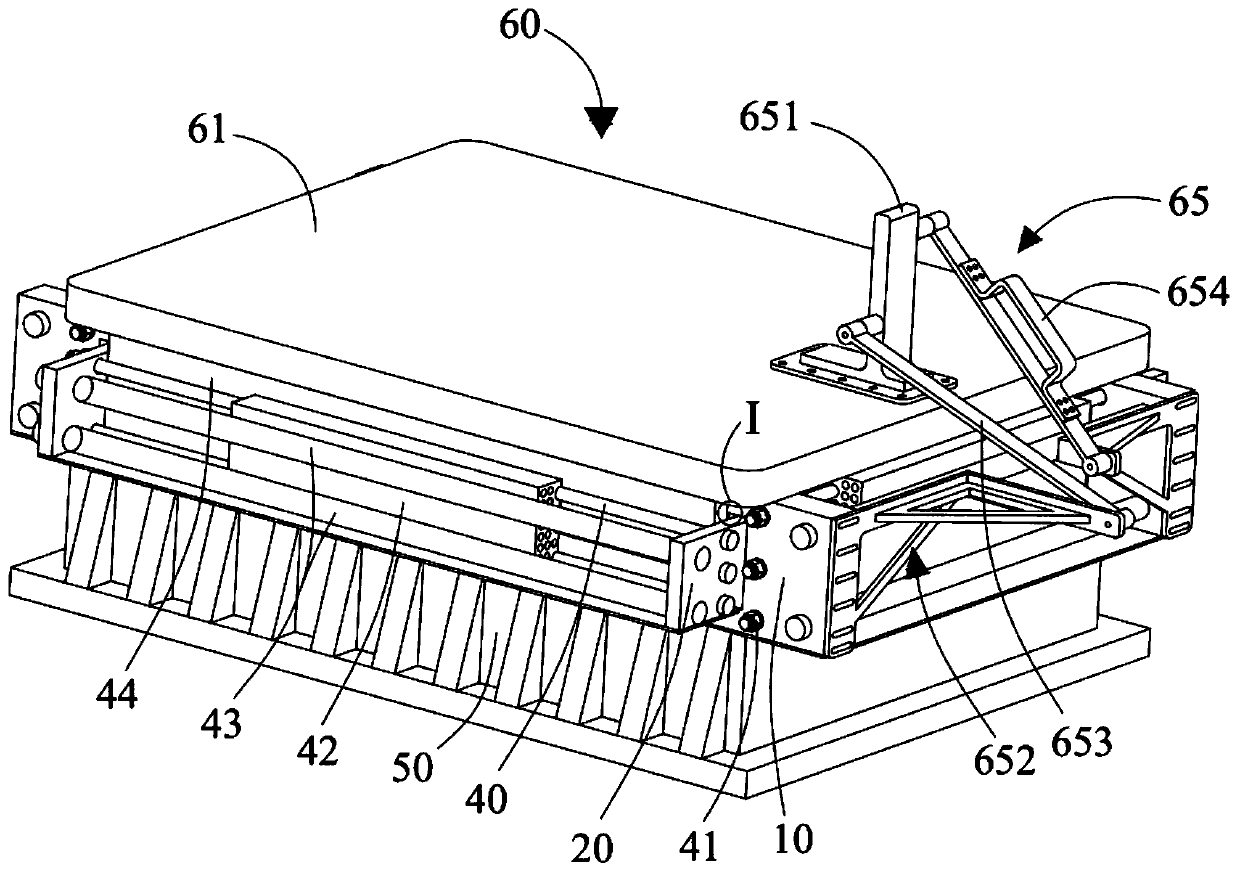

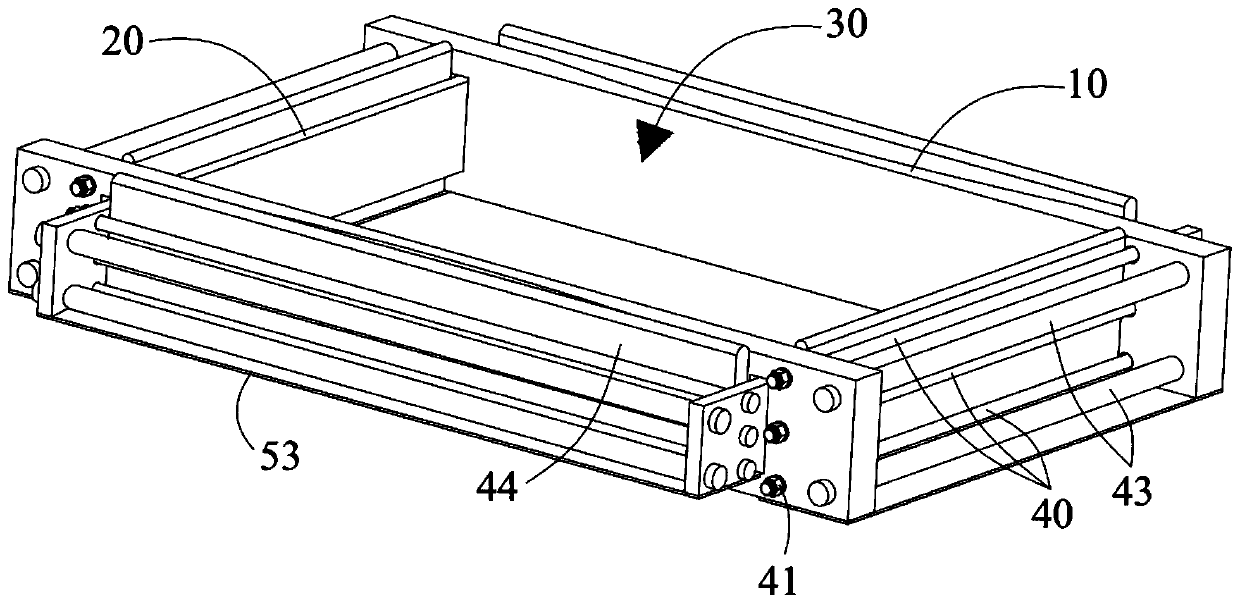

[0049] figure 1 It is a schematic diagram of the structure of the rock sample block stress field simulation device in Implementation 1. Such as figure 1 As shown, the rock sample block stress field simulation device includes a base 50 , a stress assembly and an upper cover assembly 60 . The stress assembly is arranged on the base 50, and is used to apply a stress field to the rock sample block 80 on the base 50, and the upper cover assembly 60 covers the rock sample block 80, and is used to apply a stress field to the rock sample block 80 on the base 50. Apply a temperature field.

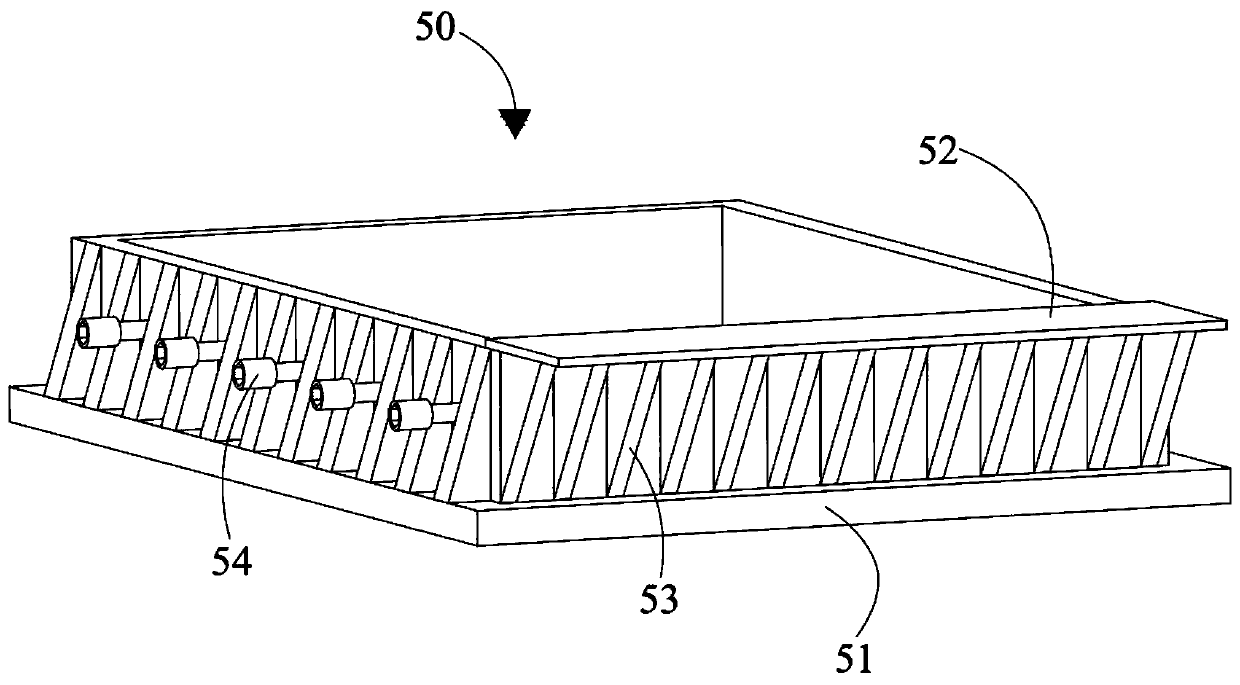

[0050] figure 2 is a structural schematic diagram of the base 50, such as figure 2 As shown, the base 50 includes a bottom plate 51 , a support plate 52 and a reinforcing rib 53 . The bottom plate 51 is generally plate-shaped and placed horizontally on the support. The support plate 52 has a plate shape and extends along a horizontal plane. The reinforcing rib 53 is connected between the b...

Embodiment 2

[0107] Figure 14 It is a structural schematic diagram of the stress field simulator of the rock sample block 80 in Implementation 2 (the base 50 is not shown). The difference between embodiment 2 and embodiment 1 is that the connection member 65 disclosed in embodiment 1 is not provided in embodiment 2, but embodiment 2 also includes a hob groove 73 and a hob mechanism 70 . In Embodiment 2, the upper cover assembly 60 further includes a hob groove 73 passing through the cover body 61 , the heating plate 62 and the heat conducting plate 63 . The hob mechanism 70 includes a moving frame 71 , a knife seat 74 and a hob 75 .

[0108] Figure 15 is a structural schematic diagram of the stress assembly and the mobile frame 71. Such as Figure 15 As shown, the moving frame 71 is connected to the first side plate 10 or the second side plate 20 , and the upper cover assembly 60 covers the stone bin 30 and is movably connected to the moving frame 71 . The mobile frame 71 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com