Aggregate elasticity modulus detection method and application

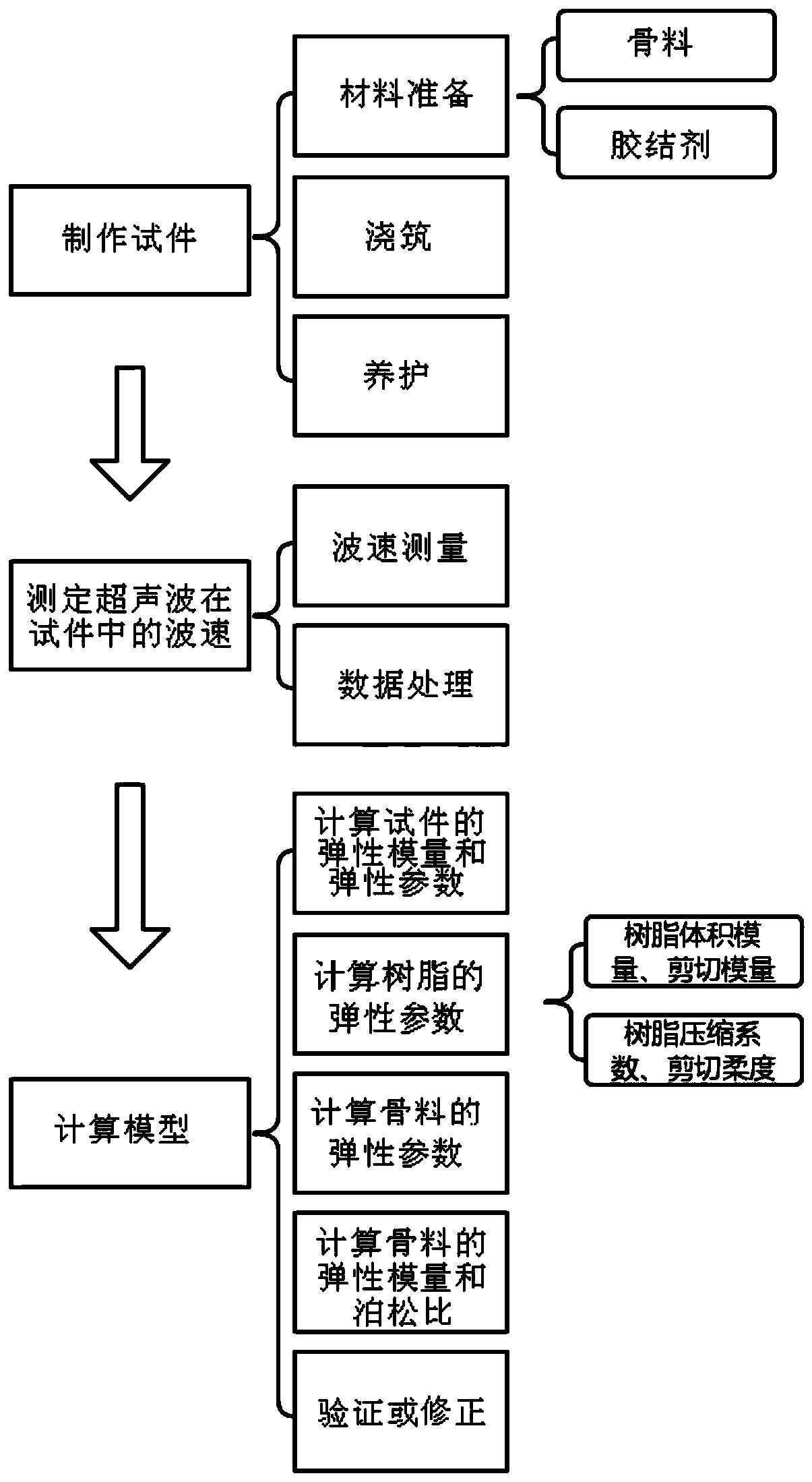

A detection method and elastic modulus technology, which are applied in processing the response signal of detection, preparation of test samples, analysis of solids using sonic/ultrasonic/infrasonic waves, etc., which can solve problems such as difficult-to-measure aggregates and differences in elastic parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

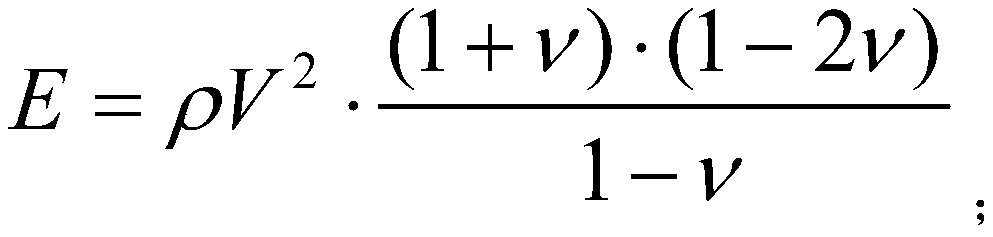

Method used

Image

Examples

example 1

[0115] Example 1. Measuring the elastic modulus of coarse aggregate and crushed stone concrete aggregate.

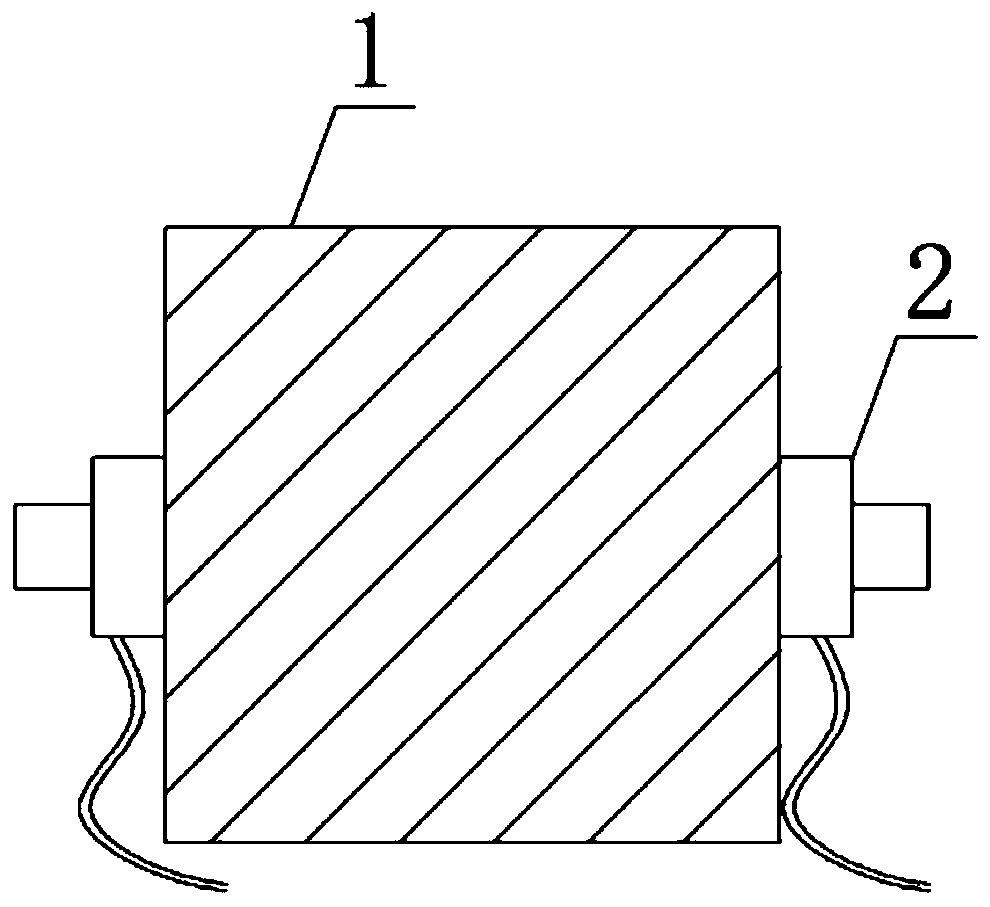

[0116] Step (1): Make a test piece.

[0117] The aggregate density required to measure the elastic modulus is about 2620kg / m 3 , it is expected to pour three cube test blocks of 100mm×100mm×100mm, and control the aggregate volume fraction in the test pieces to about 60%. Therefore, part of the aggregate was evenly taken out from the aggregate pile, and 4716g was weighed with an electronic scale. The mass of coarse aggregate in each specimen was 1572g.

[0118] After drying the coarse aggregate, the volume of the aggregate was measured by the drainage method, and the actual volume of the aggregate in the specimen was calculated to be 1.86×10 -3 m 3 .

[0119] Take about 1.8 liters of epoxy resin (Phoenix brand epoxy resin E-44 model) and 1.8 liters of curing agent 650 low-molecular-weight polyamide, and mix the epoxy resin and curing agent 650 low-molecular-weight pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com