Micro-optical assembly of 25G BiDi optical module for 5G forward transmission

An optical module and micro-optics technology, applied in the field of optical communication, can solve the problems of wasting Rx filters, Tx filters and mirrors, error sensitivity, difficulty in meeting packaging requirements, etc., to reduce assembly costs and difficulty of assembly , the effect of large incident angle error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

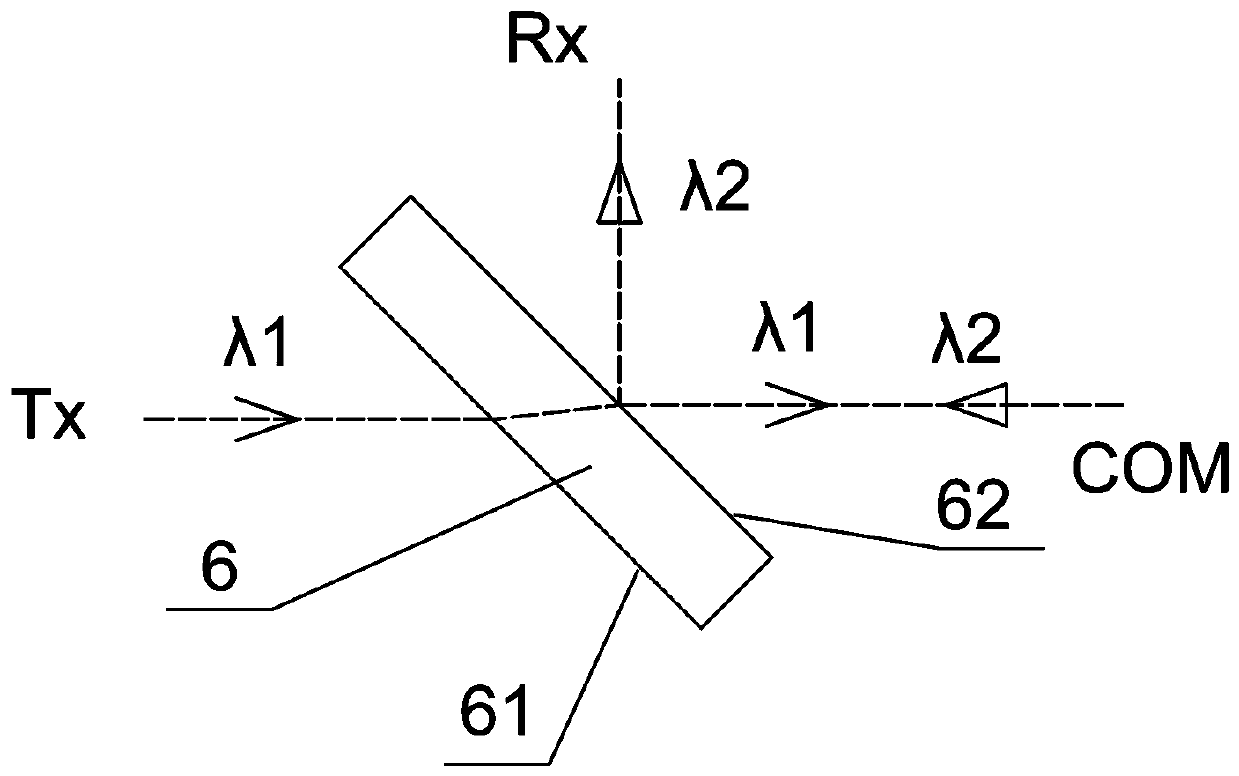

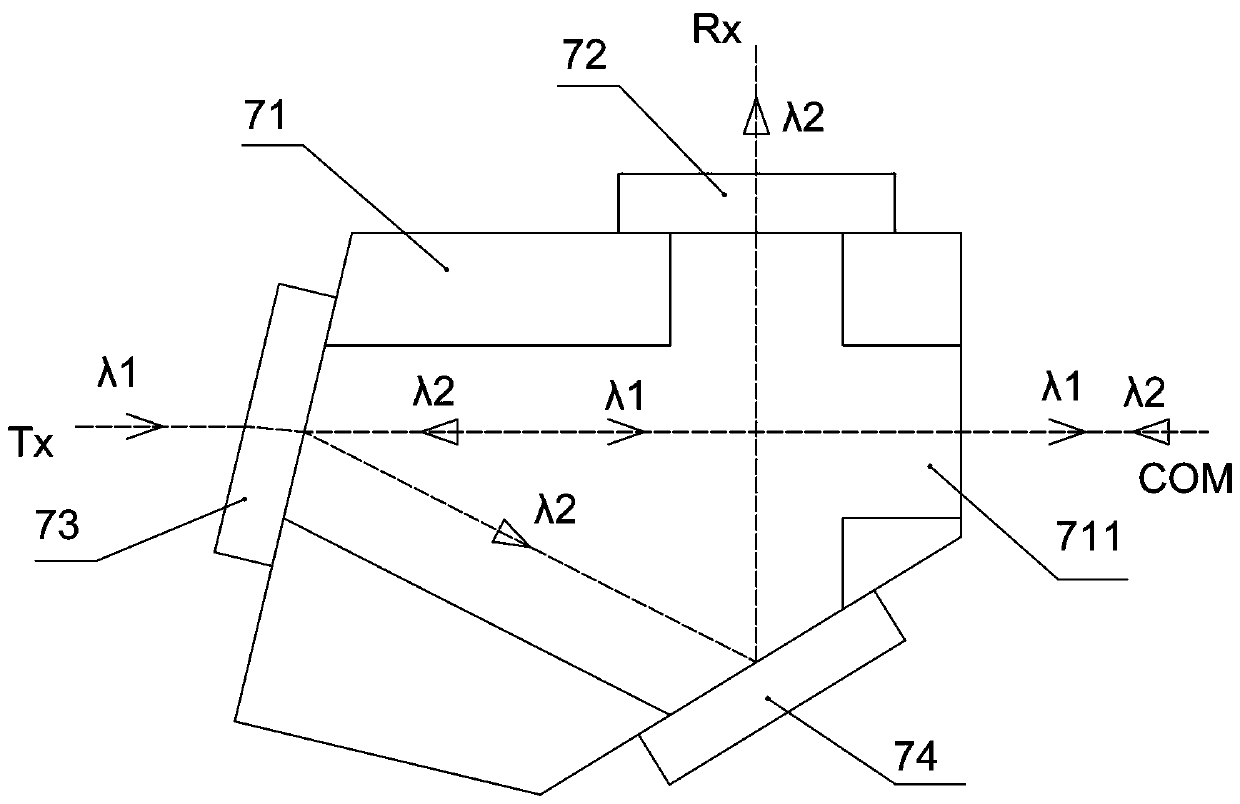

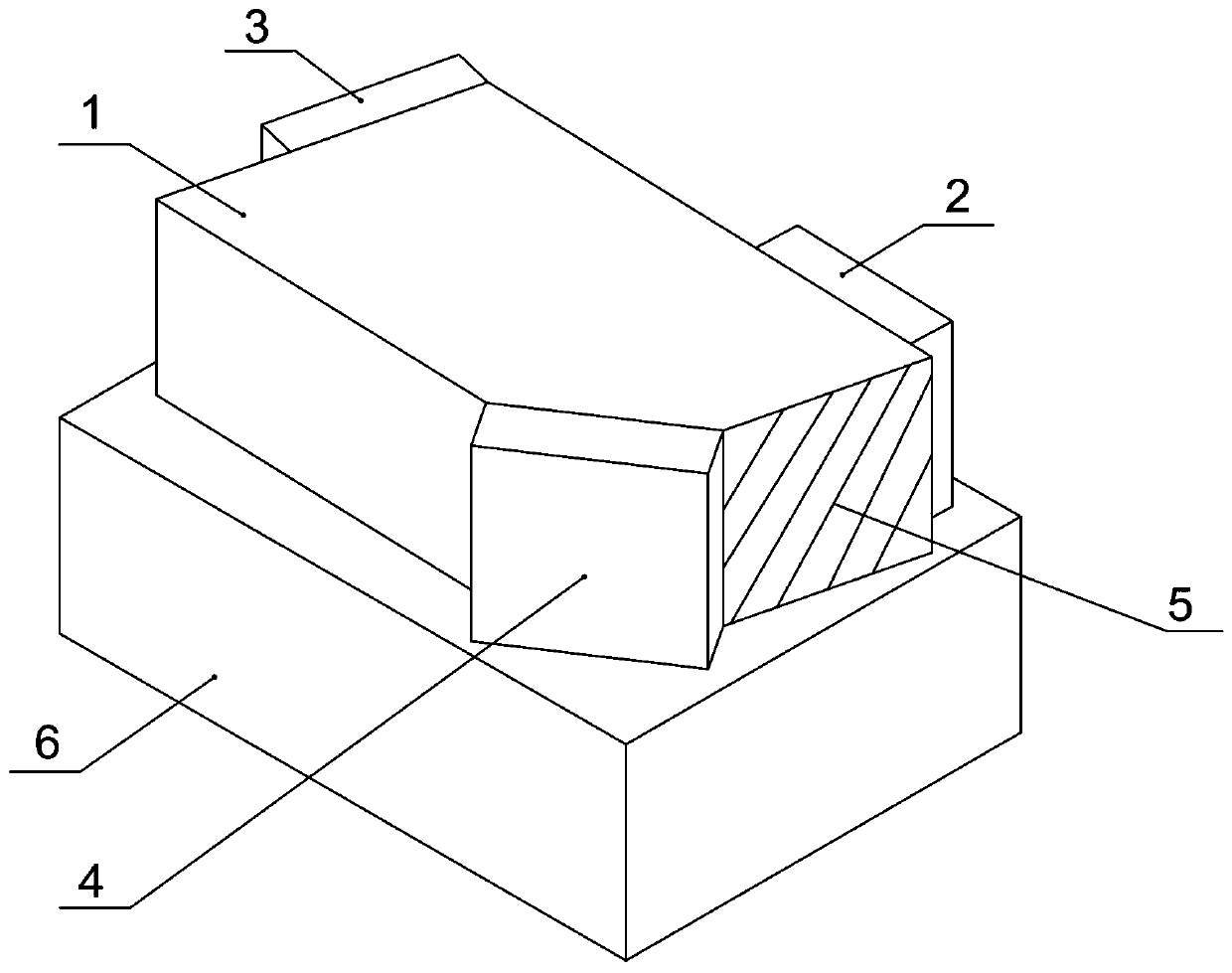

[0024] Figure 3 to Figure 6 , which is a preferred embodiment of the micro-optical component of a 25G BiDi optical module for 5G fronthaul provided by the present invention. Such as Figure 3 to Figure 6 As shown, the micro-optical component of the 25G BiDi optical module used for 5G front transmission is a dual-channel wavelength division multiplexing component with a solid structure, which includes a base plate 6 on which a glass substrate 1 in the shape of a pentagonal prism is placed. The left side 103 of the glass substrate is pasted with the Tx filter 3 for entering the emitted light, and the right side 101 of the glass substrate is coated with an anti-reflection film 5 for entering the receiving light and exiting for the emitting light. The lower slope 104 is pasted with a reflector 4, and the upper side 102 of the glass substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com