Hearth slagging prediction system and method for ultra-supercritical pulverized coal boiler

A pulverized coal boiler and ultra-supercritical technology, which is applied in prediction, neural learning methods, biological neural network models, etc., can solve problems such as low prediction accuracy, high device cost, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, some modifications can be made to the present invention without departing from the principles of the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

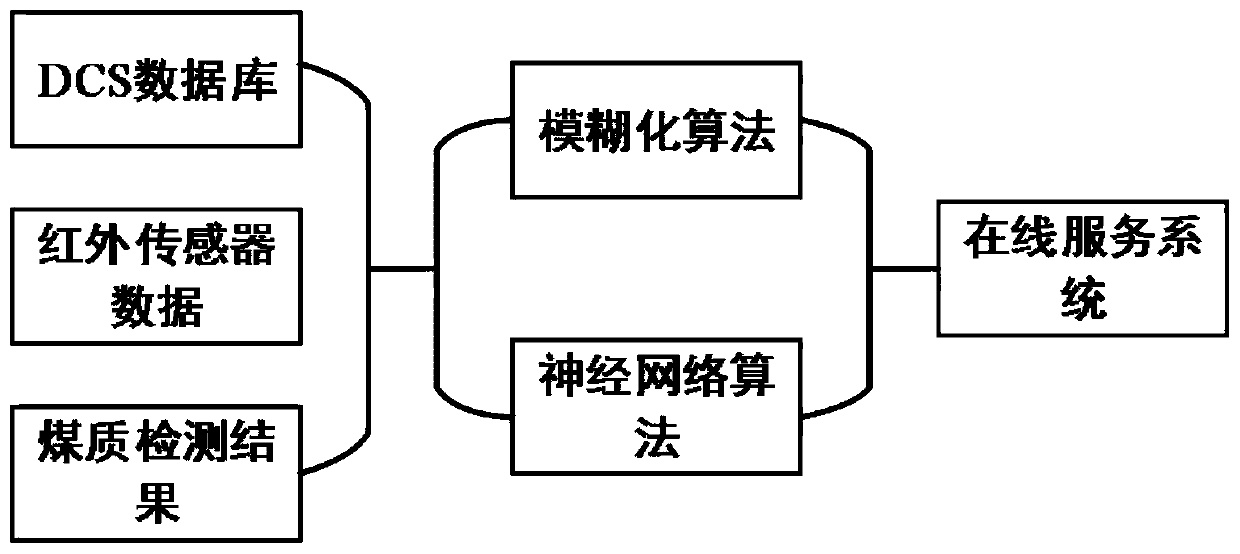

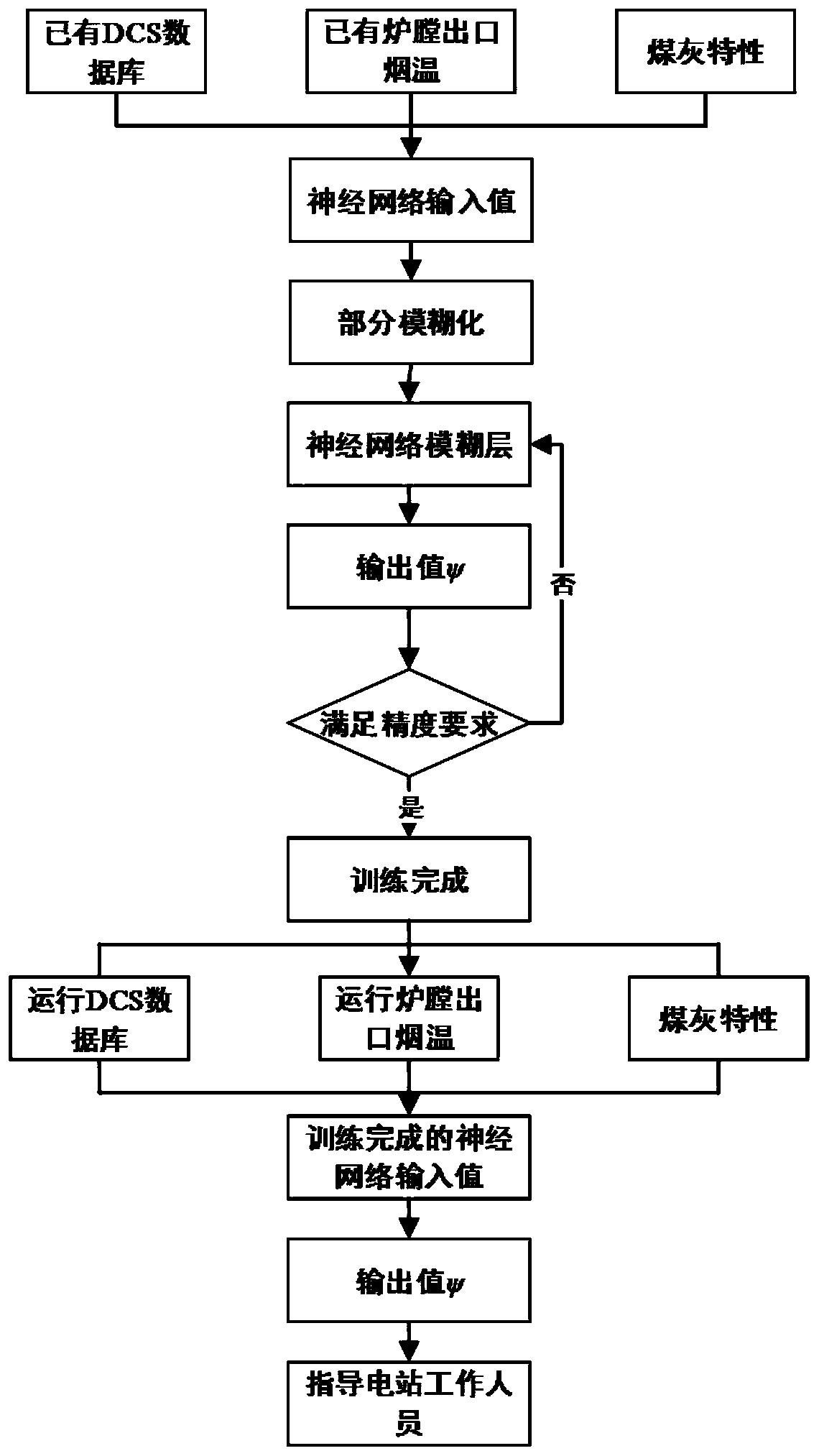

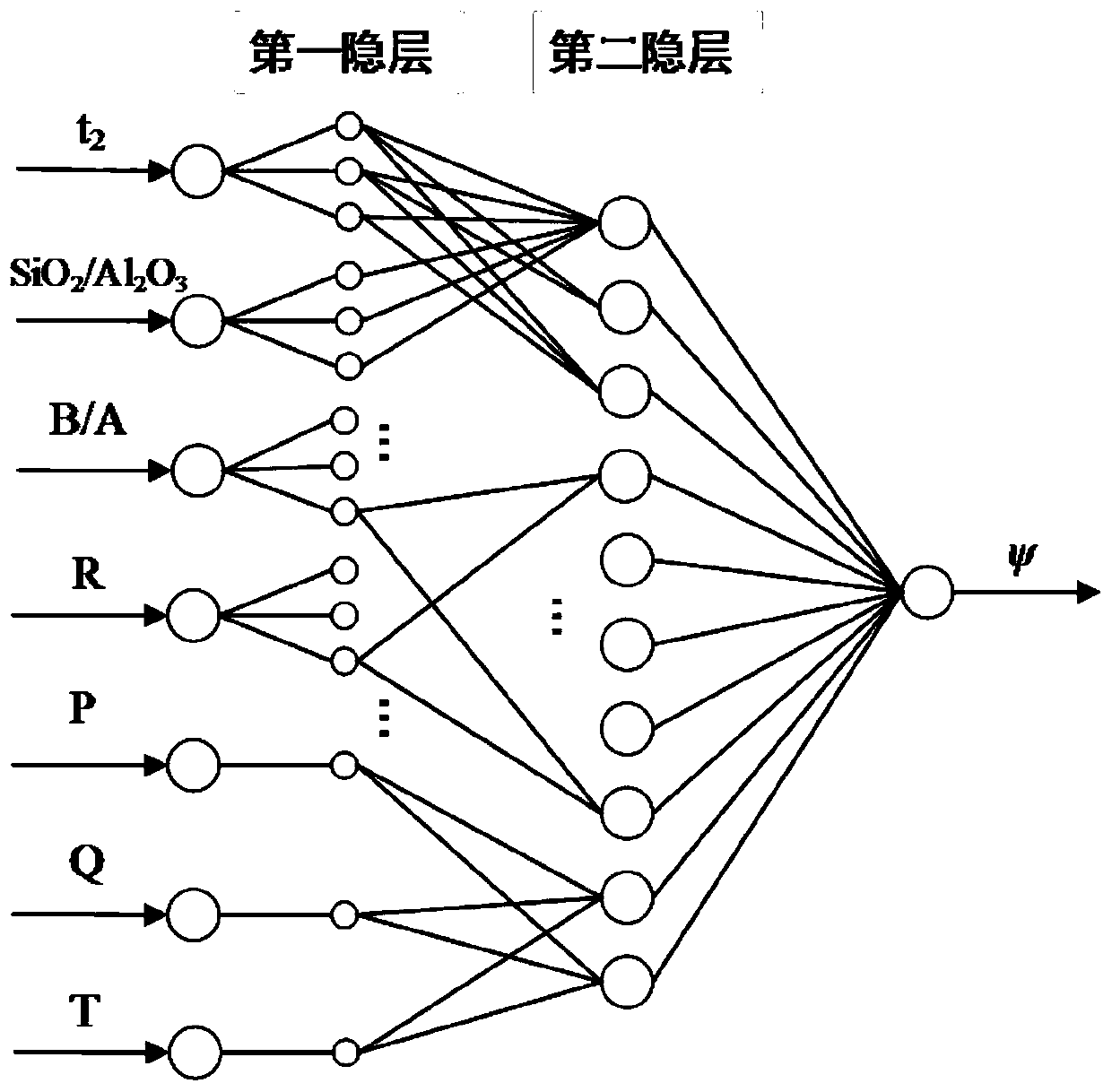

[0054] The ultra-supercritical pulverized coal boiler furnace slagging prediction system of the present invention consists of three major modules: the main power station boiler database, the neural network algorithm system, and the online service system. , coal ash characteristic parameters and furnace outlet flue temperature measured by the infrared sensor at the furnace outlet are imported into the neural network algorithm database, and the input value is partially fuzzy process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com