Integrated power battery system of high-power hybrid power locomotive

A technology of power battery and hybrid power, which is applied in the field of rail transit, can solve the problems of high cost and long production cycle, and achieve the effect of improving carrying capacity, improving production efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

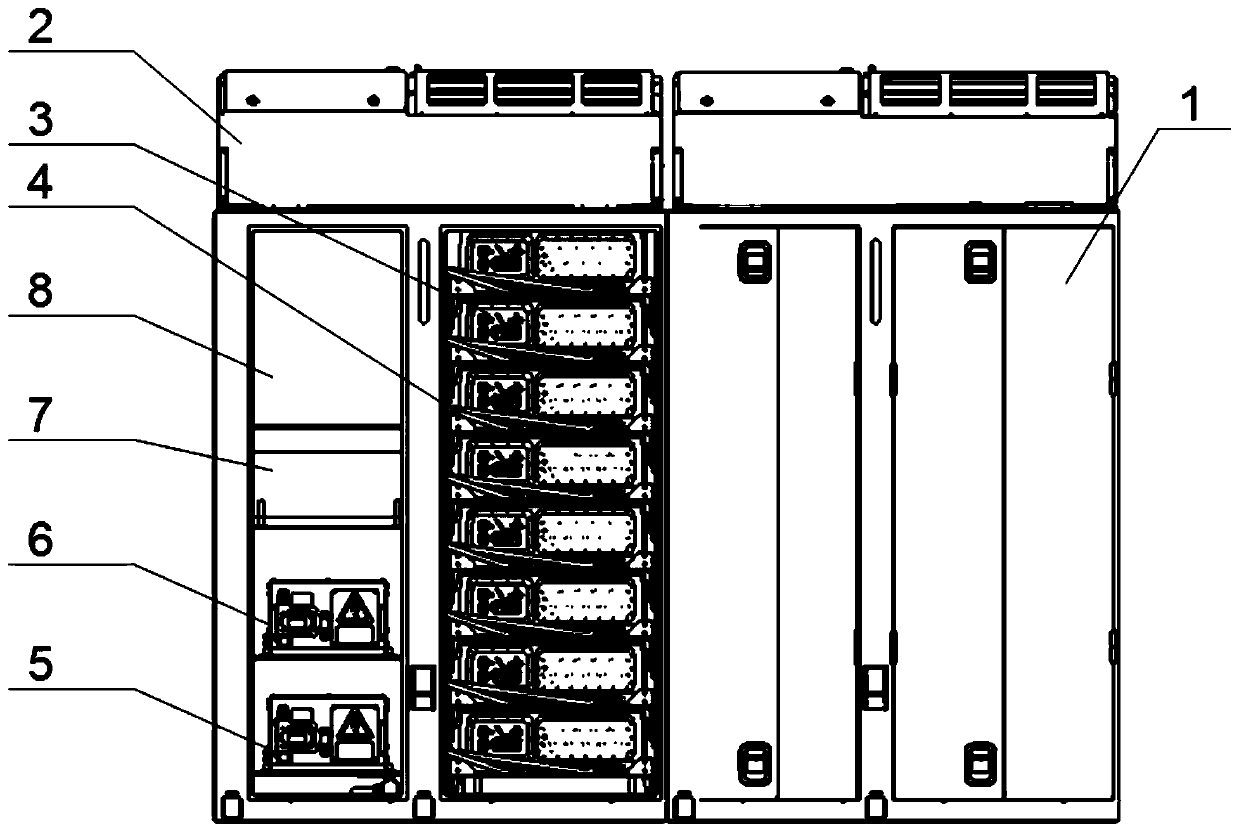

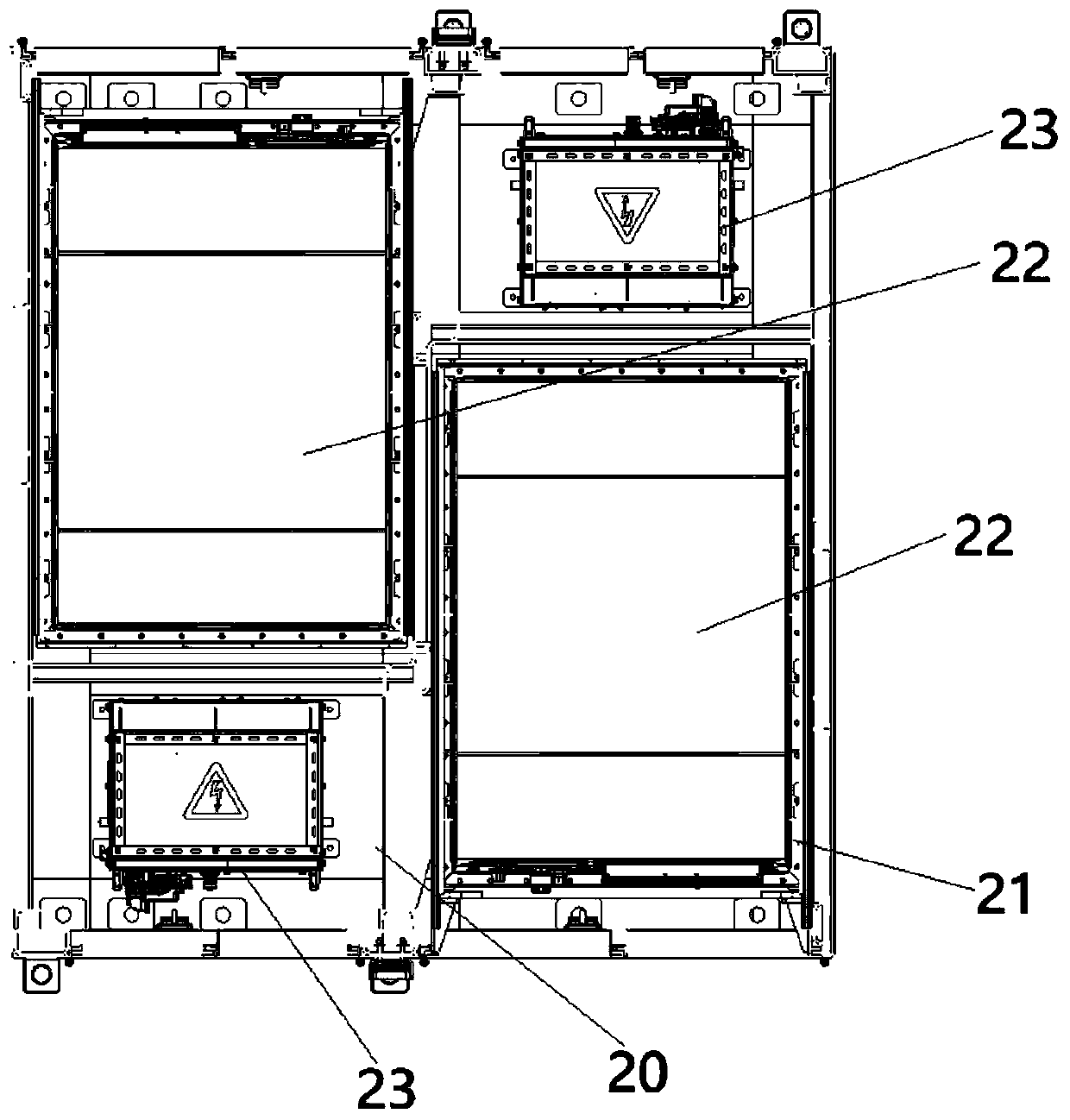

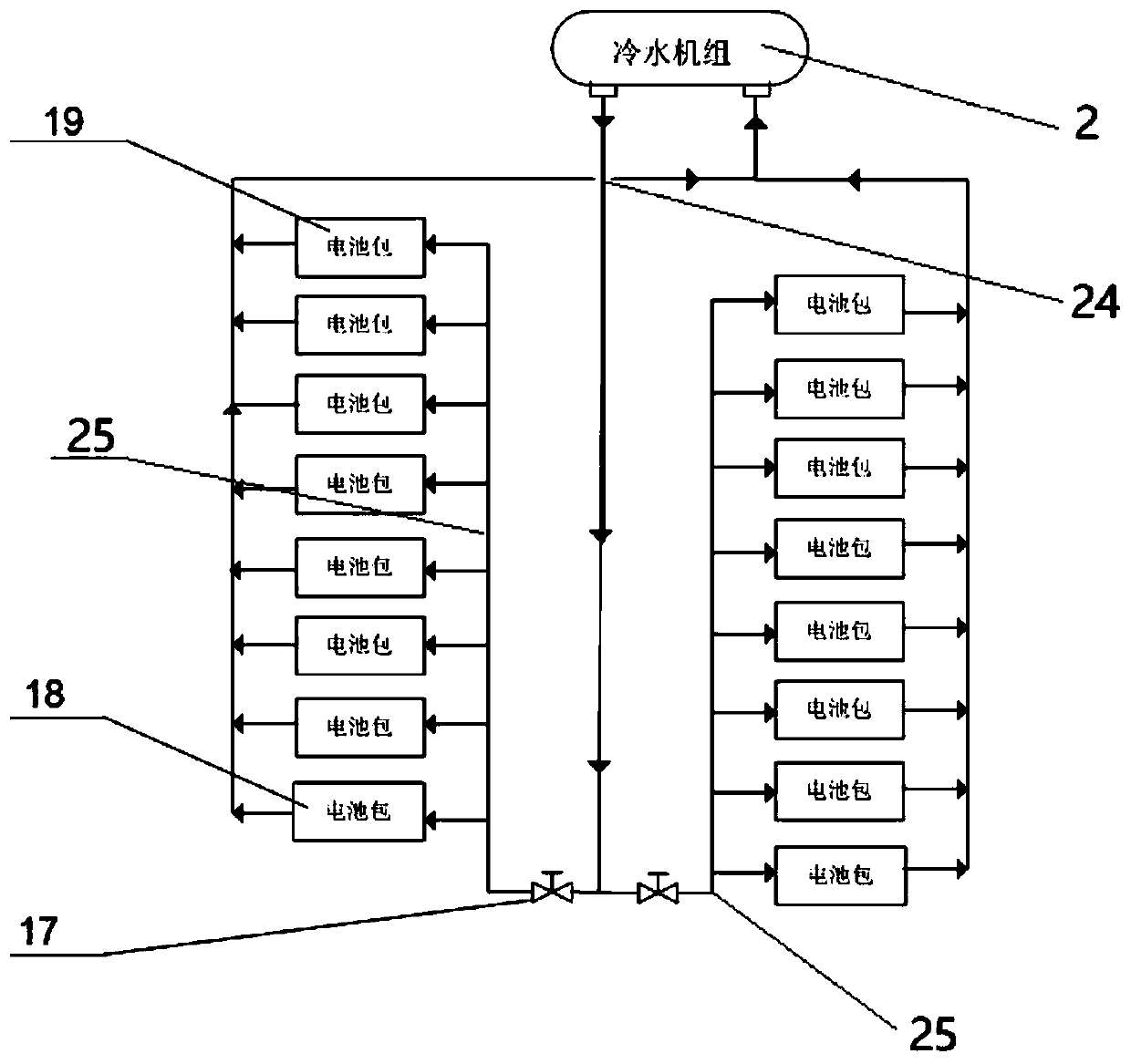

[0033] The embodiment is basically as figure 1 As shown: this embodiment provides a high-power hybrid locomotive integrated power battery system, which is applied to a high-power hybrid locomotive with a loading capacity greater than 1000kWh; it includes two power battery devices 1, two power battery devices 1 are installed side by side on the vehicle frame, and each power battery device 1 is equipped with a chiller 2, and the two power battery devices 1 are arranged in parallel, so that when one of the power battery devices 1 fails, the hybrid locomotive still can function normally; specifically, as figure 2 As shown, each power battery device 1 has a first chamber 20 and a second chamber 21 arranged side by side, and the first chamber 20 and the second chamber 21 are divided and arranged with a battery compartment 22 and an equipment compartment 23 , and the battery compartment 22 and the equipment compartment 23 in the first chamber 20 and the second chamber 21 are arrang...

Embodiment 2

[0039] Embodiment 2 is basically the same as Embodiment 1, the difference is: please combine figure 1 , Figure 4 and Figure 5 As shown, this embodiment provides an integrated power battery system for a high-power hybrid electric locomotive, which is fully considered in combination with the fact that the power battery pack cannot bear a large load and needs to be easy to install and maintain. The installation is designed as a drawer structure; specifically, a slide rail composition 11 is provided in the battery room 3, and the slide rail composition 11 includes a slide rail 15 and a slide rail 16, and the slide rail 16 is welded on the steel structure 13 of the battery room, and the slide rail 15 is welded with the battery mounting plate 10 arranged at the bottom of the battery pack 9, so that the battery pack 9 can be pulled out from the side of the battery chamber 3 along with the battery mounting plate 10. The structural design and installation method are simple, safe and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com