Making of high-protein pasteurization drinking type yogurt

A technology of pasteurization and pasteurized milk, which is applied in the direction of milk preparations, applications, dairy products, etc., and can solve problems such as rough taste, poor shear resistance, and difficulty in meeting the taste requirements of drinking yogurt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

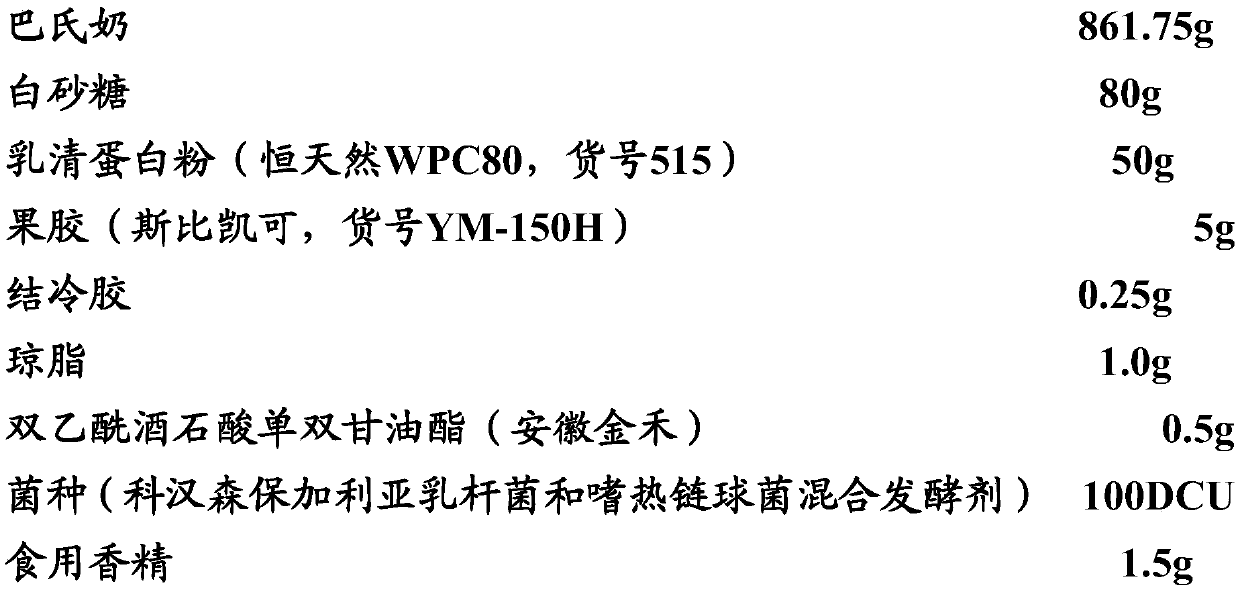

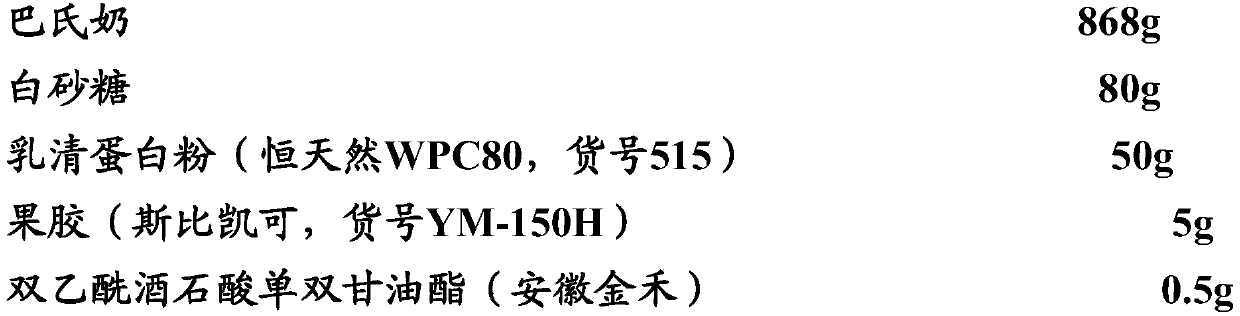

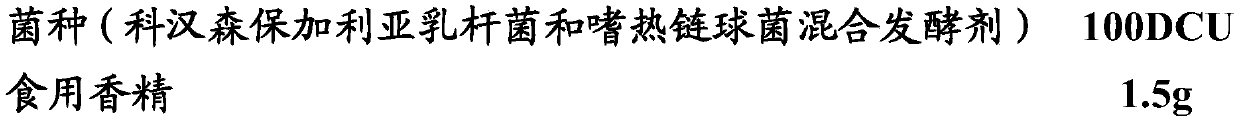

[0043] Product formula composition (contained in every 1000g product)

[0044]

[0045] Process:

[0046] 1) RO membrane filtration process: the pasteurized milk is separated by RO membrane filtration equipment to obtain RO retentate and RO permeate.

[0047] Fat content of RO retentate (%): fat=4.3

[0048] RO retentate protein content (%): protein = 3.9

[0049] According to the above process, the RO permeate which accounts for 15% of the pasteurized milk is prepared.

[0050] 2) Fermentation broth preparation: heat pasteurized milk RO retentate liquid accounting for 55% of the total amount to 50-55° C., mix whey protein powder, agar, gellan gum, white granulated sugar accounting for 90% of the total amount of white granulated sugar, bismuth Acetyl tartrate mono-diglycerides are added to the RO retentate of pasteurized milk, and the chemical equipment with mixing, dispersing, shearing and emulsifying effects is used to make the material liquid into a uniform and disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com