Stabilizer combination and application of stabilizer combination in beverage preparation

A stabilizer and beverage technology, applied in applications, dairy products, milk preparations, etc., can solve the problems of viscosity of beverages, affecting consumers' drinking experience and appearance, and poor emulsification stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

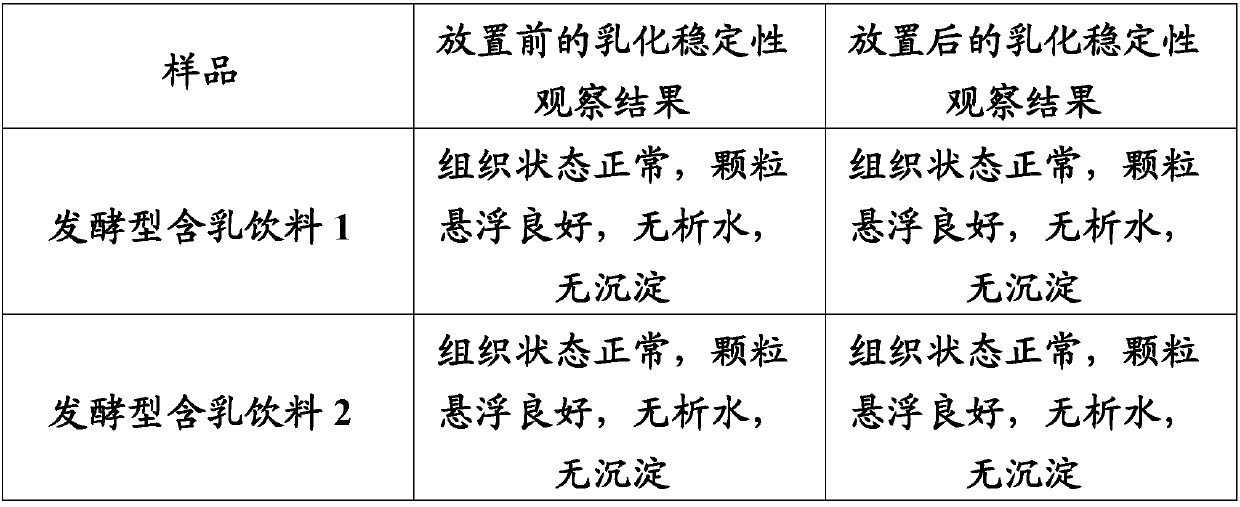

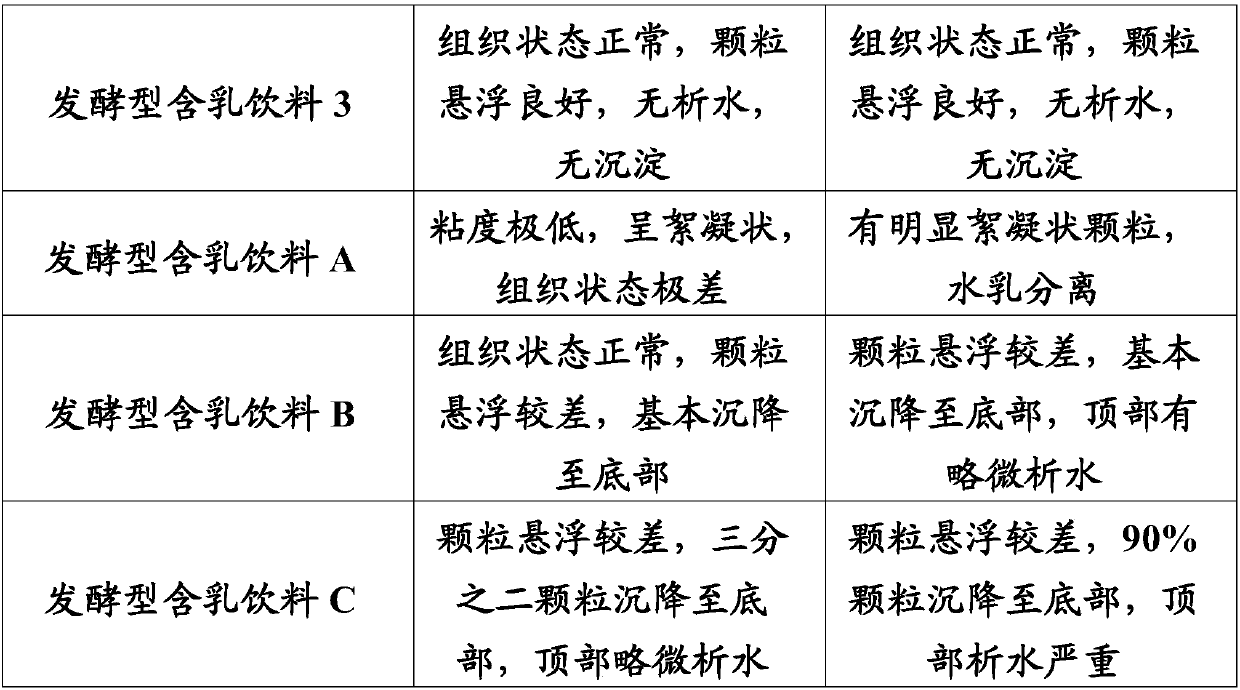

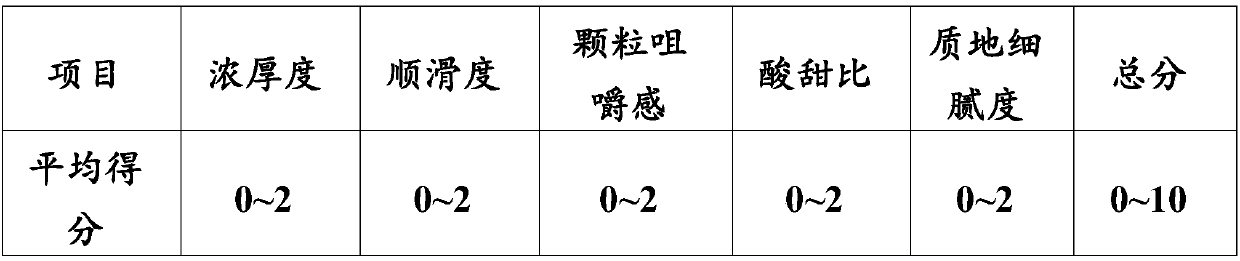

Examples

Embodiment 1

[0103] Example 1 Preparation of fermented milk-containing beverage 1

[0104](1) 818.25g of ingredients were heated to 55°C with water, 125g of full-fat milk powder was added to the water and mixed evenly, and left to stand for hydration for 30 minutes to obtain reduced milk;

[0105] (2) adding 20g of sucrose, 30g of acetylated distarch phosphate, 1g of agar and 0.75g of gellan gum into the reduced milk obtained in step (1) and mixed uniformly to obtain a mixture;

[0106] (3) the mixture obtained in step (2) is subjected to homogenization treatment, and the primary pressure of the homogenization treatment is 180 bar, and the secondary pressure is 30 bar to obtain a homogeneous material;

[0107] (4) keeping the homogeneous material obtained in step (3) at 95° C. for 300 s to carry out sterilization treatment to obtain sterilization material;

[0108] (5) the sterilizing material obtained in step (4) is cooled to 42° C., inoculated with lactic acid bacteria starter (the rat...

Embodiment 2

[0113] Example 2 Preparation of fermented milk-containing beverage 2

[0114] (1) 83.34kg of ingredients were poured into the chemical tank with water and heated to 55°C, 12.5kg of full-fat milk powder was also added to the chemical tank, stirred at 960r / min for 20 minutes, and the chemical effect was checked (no visible to the naked eye). Particulate matter), left to hydrate for 30 minutes to make reduced milk;

[0115] (2) 1.5kg of sucrose, 2.5kg of acetylated distarch phosphate, 100g of agar, and 60g of gellan gum were added to the chemical tank and stirred and mixed with reduced milk, and the stirring speed was 960r / min, and the stirring time was 20 minutes to obtain the mixture;

[0116] (3) homogenizing the mixture obtained in step (2), the primary pressure of the homogenizing treatment is 160 bar, and the secondary pressure is 30 bar, to obtain a homogeneous material;

[0117] (4) sterilizing the homogeneous material obtained in step (3) at 95° C. for 300 s to obtain...

Embodiment 3

[0125] Example 3 Preparation of fermented milk-containing beverage 3

[0126] (1) 5.7 tons of ingredients are poured into the chemical tank with water and heated to 55°C, 900kg of full-fat milk powder is also added to the chemical tank, mixed with a shear pump for 15 minutes, and the chemical effect is checked (no visible to the naked eye). Particulate matter), left to hydrate for 25 minutes to make reduced milk;

[0127] (2) 140kg of sucrose, 200kg of acetylated distarch phosphate, 18kg of agar, and 7.5kg of gellan gum are added to the chemical tank and mixed with reduced milk, and the mixing condition is to use a shear pump to circulate for 15 minutes, and check the chemical effect (no Particles visible to the naked eye) to obtain a mixture;

[0128] (3) the mixture obtained in step (2) is subjected to homogenization treatment, and the primary pressure of the homogenization treatment is 150 bar, and the secondary pressure is 30 bar to obtain a homogeneous material;

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com