A kind of flexible conductive film and its preparation method, sensor

A flexible conductive and flexible film technology, applied in chemical instruments and methods, electromagnetic measuring devices, electric/magnetic solid deformation measurement, etc., can solve the problems of flexible conductive films that are easy to break, and achieve improved stretching range and high stretching sensitivity , Good device stability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] Correspondingly, the embodiment of the present application also provides a method for preparing a flexible conductive film, such as Figure 7 shown, including:

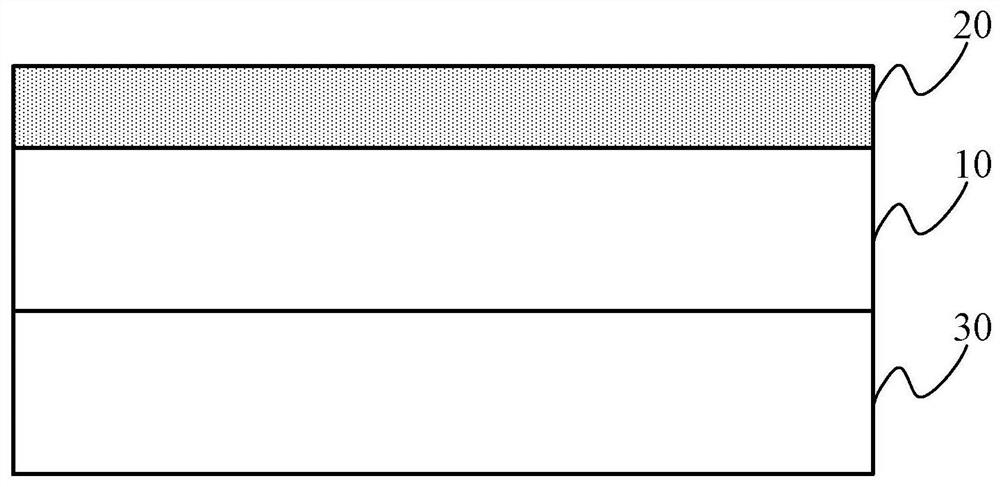

[0066] S101: Provide a substrate, the first surface of the substrate is arranged with a plurality of grooves of preset shapes; refer to Figure 8 , Figure 8 is a schematic cross-sectional structure diagram of the substrate; Figure 8 Among them, 40 represents the substrate, and when the substrate is an anodized aluminum template, the reference numeral 41 represents the aluminum metal layer, 42 represents the first aluminum oxide layer, and 43 represents the second aluminum oxide layer.

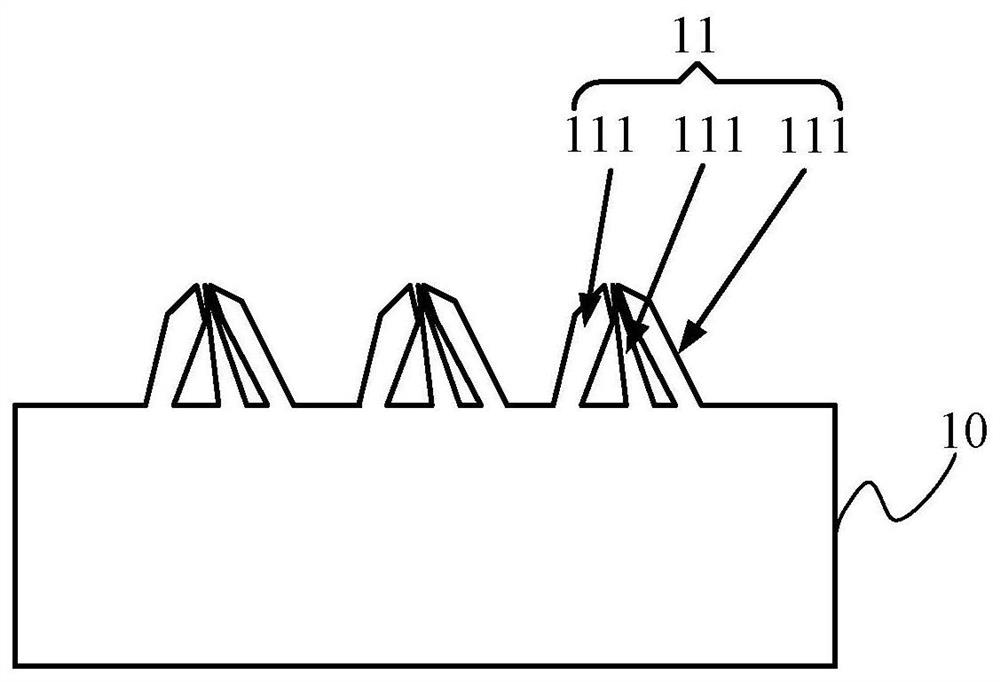

[0067] S102: Form a flexible thin film on the first surface of the substrate, the flexible thin film includes a microstructure protruding into the groove and a main body covering the exposed surface of the microstructure and the first surface; refer to Figure 9 , Figure 9 is a schematic diagram of the substrate and its s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com