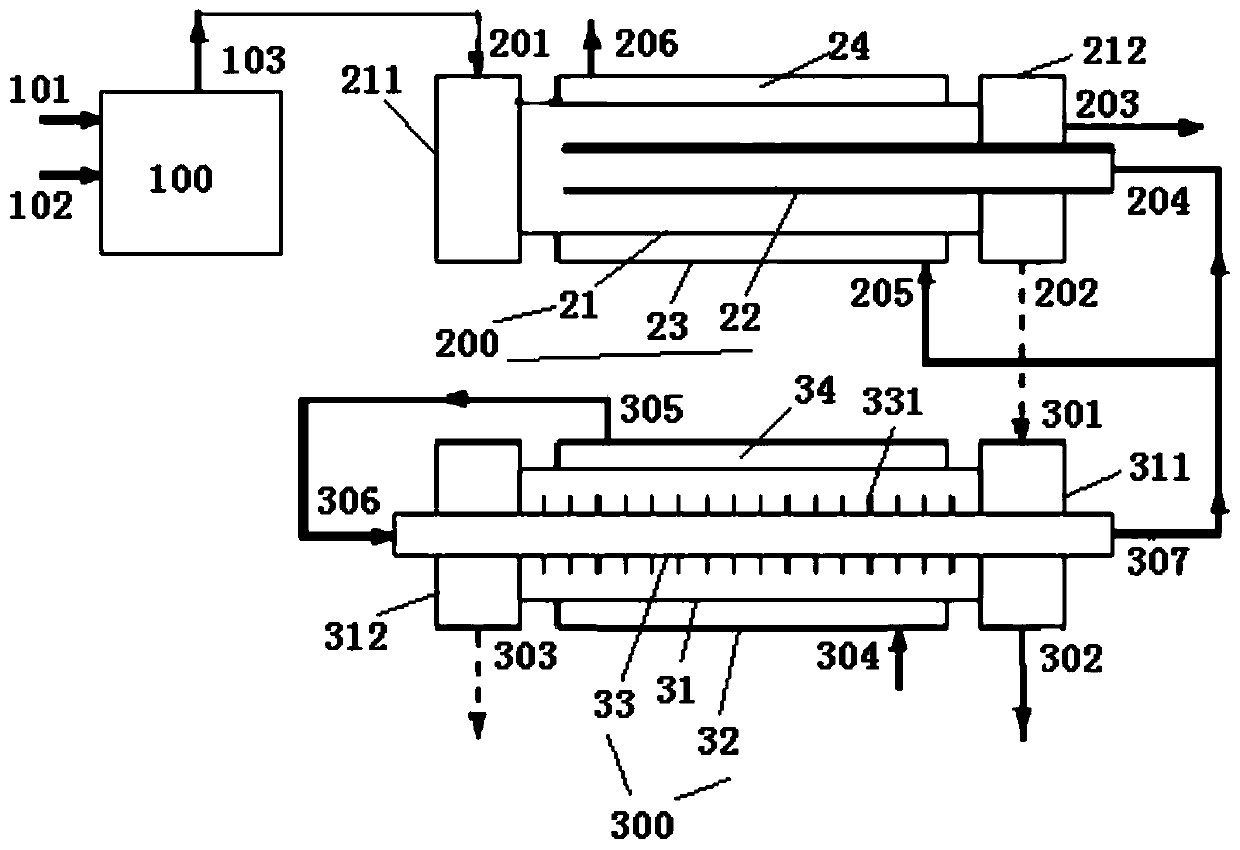

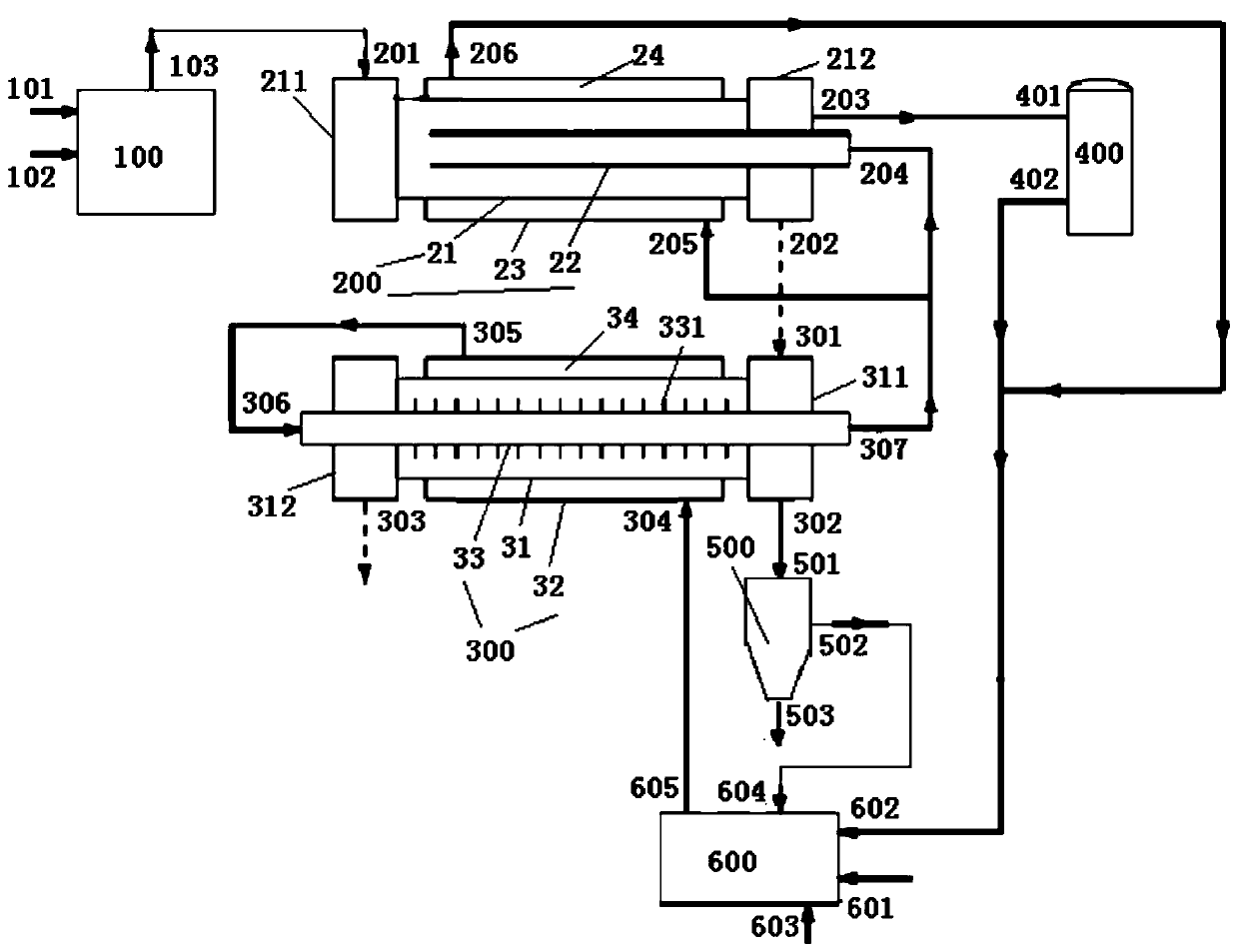

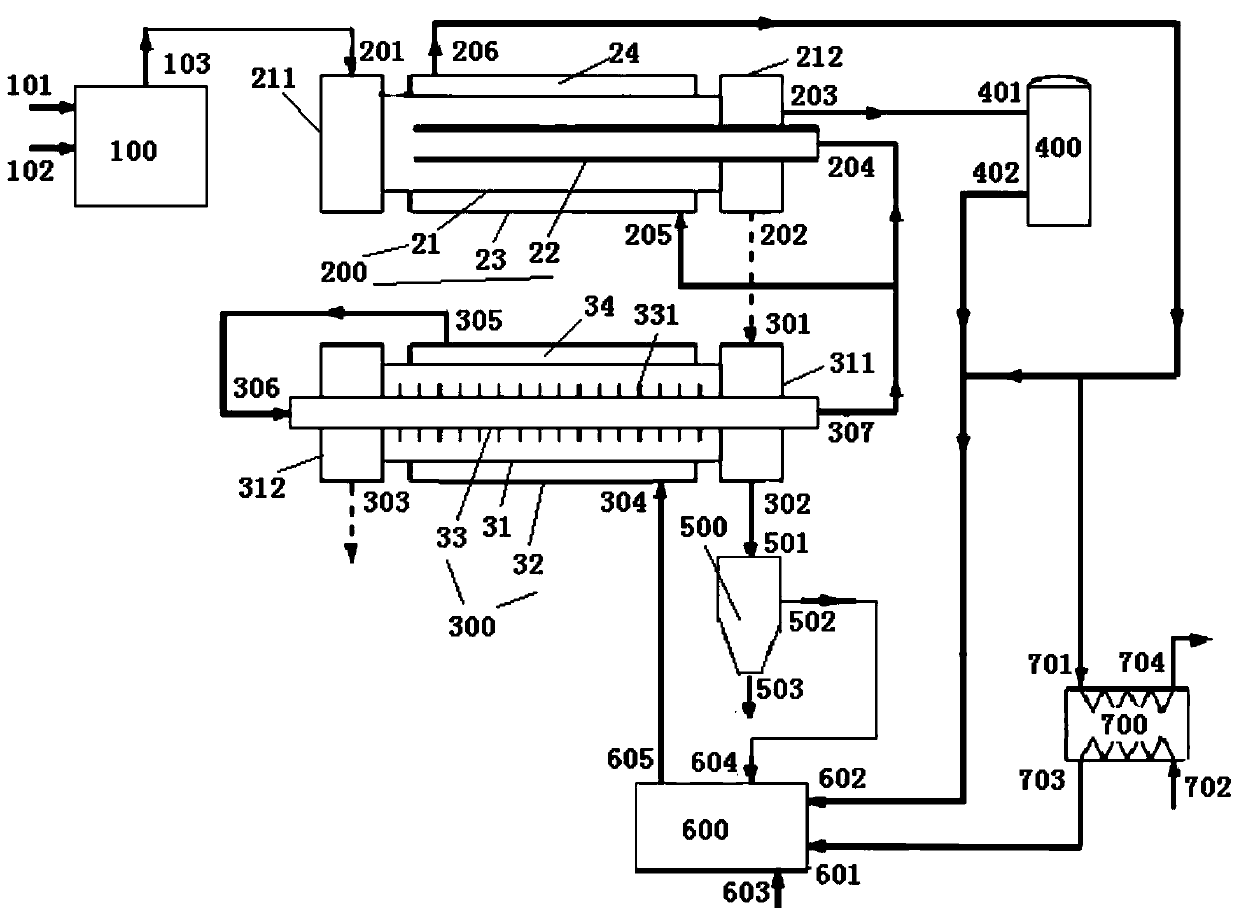

System and method for treating organic solid waste in villages and towns

A technology for organic solid waste and villages and towns, which is applied in the field of systems for treating organic solid wastes in villages and towns, can solve problems such as non-point source pollution in rural living, and achieve the effects of improving drying efficiency, large porosity, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0091] After crushing domestic waste (moisture content 50wt%), mix it with livestock and poultry manure (moisture content 80wt%) and sludge (moisture content 80wt%) according to the ratio of 3:1:1, and mix in the mixer Evenly, mixed organic solid waste is obtained, and the obtained mixed organic solid waste is sent into the dryer through a screw conveyor, and the first dry hot air (temperature is 380 ° C) is supplied to the inner tube of the dryer, and the second dry hot air ( The temperature is 380°C) is supplied to the heating space of the dryer, that is, the first drying hot air is directly heated with the mixed organic solid waste in the inner cylinder of the dryer, and the second dry hot air is indirectly heated with the mixed organic solid waste in the inner cylinder of the dryer , and finally obtain the dry material with the moisture content reduced to 19.7wt%, the second drying hot air becomes dry cold air (temperature is 220°C) after heat exchange, and the second dry h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com