Method for preparing tungsten needle tip electrode based on electric field evaporation and implementing device thereof

A technology of tungsten needles and electrodes, which is applied in the field of preparation of tungsten needle-point electrodes, can solve the problems of complex preparation devices and low repeatability of needle points, and achieve the effects of improving preparation efficiency, high product repeatability, and simple devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

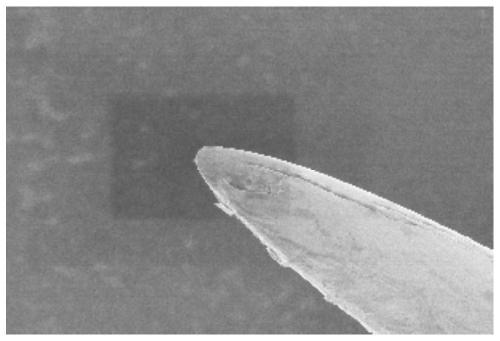

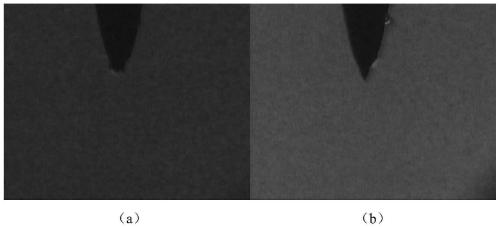

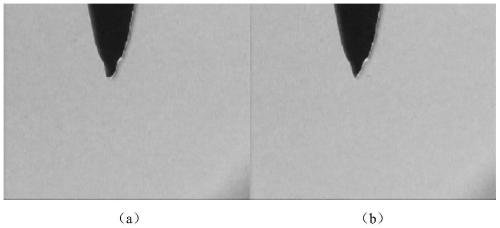

[0029] Embodiment 1: The method for preparing tungsten tip electrodes based on electric field evaporation described in this embodiment includes the following steps:

[0030] Preliminary refinement processing steps:

[0031] Before preparing the needle-tip electrode, the tungsten needle electrode should be pre-prepared, that is, the preliminary thinning treatment. There are two treatment methods:

[0032] First, the method of electrochemical corrosion is adopted. The diameter of the tungsten wire used in the method is 0.5 mm, and the electrolyte solution is 2 mol / L NaOH solution. The thinner the diameter of the tungsten wire, the thinner the etched needle tip. However, the diameter of the tungsten wire is too thin and the mechanical strength is not enough, which is not conducive to the utilization of follow-up work, so this method can only be used as a preliminary thinning treatment. In the relevant experiments in the atmospheric environment, tungsten wires with a diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com