A kind of cotton-wool blended yarn fabric and preparation method thereof

A technology of blended yarn and cotton wool, which is applied in the direction of yarn, textile, textile and paper making, can solve the problems of high price, difficult washing, itching, etc., achieve surface friction coefficient and strength improvement, improve comfort and practicability, and improve cohesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

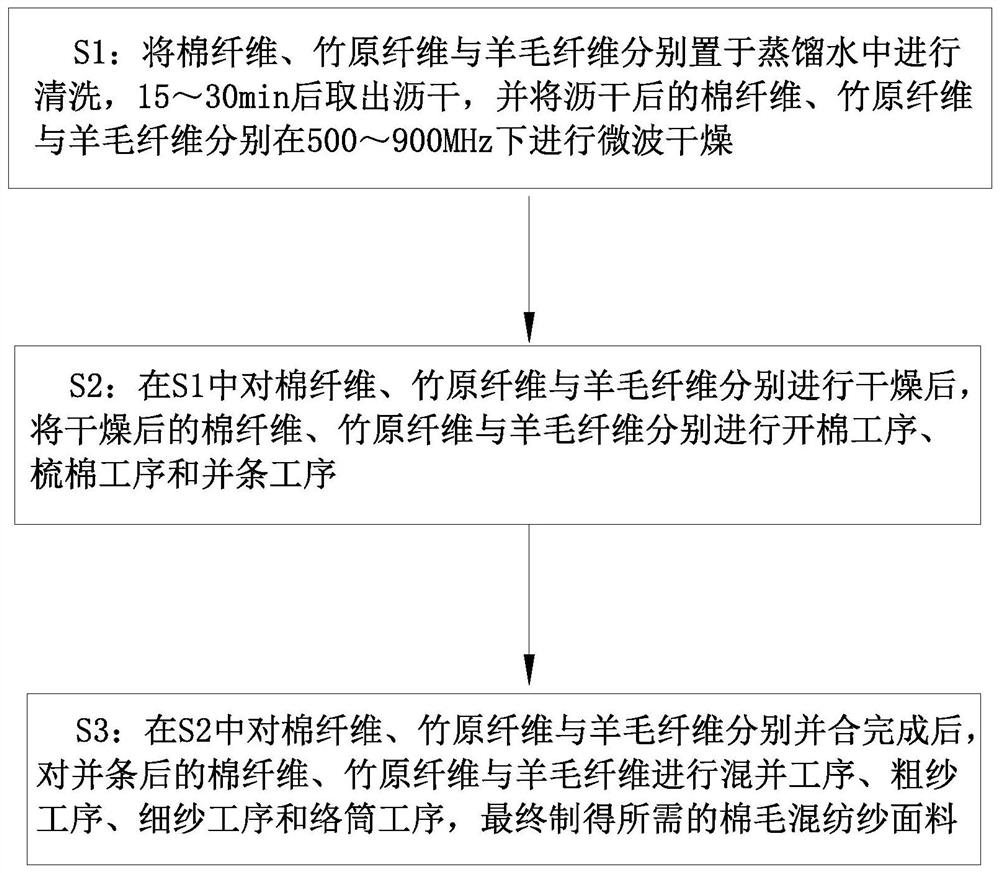

[0026] A preparation method of cotton-wool blended yarn fabric, the method is suitable for preparing the above-mentioned cotton-wool blended yarn fabric, and the method comprises the following steps:

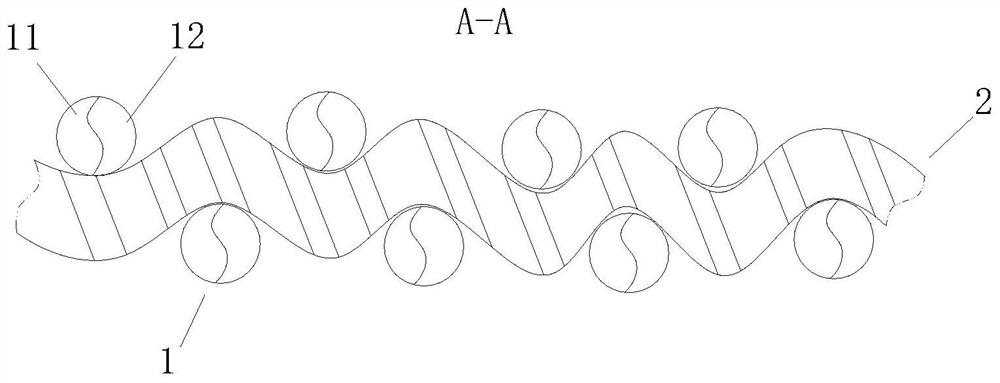

[0027] S1: Wash the cotton fiber 11, bamboo fiber 12 and wool fiber 21 in distilled water respectively, take them out and drain after 15-30 minutes, and put the drained cotton fiber 11, bamboo fiber 12 and wool fiber 21 in 500 Microwave drying at ~900MHz; by washing the cotton fiber 11, bamboo fiber 12 and wool fiber 21 in distilled water, the dust and impurities adhering to the fiber surface are effectively removed, and the purity of the subsequent fiber processing is improved. and use effect;

[0028] S2: After drying the cotton fiber 11, bamboo fiber 12 and wool fiber 21 respectively in S1, the dried cotton fiber 11, bamboo fiber 12 and wool fiber 21 are respectively subjected to an opening process, a carding process and a drawing process ; Cotton fiber 11, bamboo fiber 12 a...

Embodiment approach

[0032] As an embodiment of the present invention, the impregnating liquid where the bamboo fiber 12 and the wool fiber 21 are located also includes an additive liquid B, and the components of the additive liquid B and the parts by mass thereof are: diphenylmethane diisocyanate 20 -30 parts, 10-16 parts of polytetrahydrofuran ether glycol, 4-6 parts of polyether triol, 2-4 parts of diethyltoluenediamine and 2-4 parts of butanediol; The composition of the composition has a waterproof effect when it is dried and solidified. At this time, by adding the additive liquid B to the impregnating liquid where the bamboo fiber 12 and the wool fiber 21 are located, the above-mentioned components in the additive liquid B can effectively adhere to the two fibers. In the pits produced on the surface and ultrasonic treatment, a layer of waterproof protective film is formed on the surface after microwave drying, so that the fabric made of bamboo fiber 12 and wool fiber 21 can be waterproof when ...

Embodiment 1

[0036] Take 100 parts of cotton fiber by weight and put it in distilled water, then use 200W ultrasonic waves to ultrasonically treat the wool fiber and cotton fiber respectively, take them out and drain them after 15 minutes, and then place the cotton fiber after ultrasonic treatment in 10 parts of soaking liquid , vacuum impregnated at -0.05MPa for 1h, and the obtained cotton fibers were microwave-dried at 500MHz, and then the dried cotton fibers were subjected to the opening process, carding process and drawing process respectively, and the drawn cotton fibers were Cotton fibers are sequentially processed through blending process, roving process, spun yarn process and winding process, and finally the required fabric is produced, and the comfort and moisture absorption and air permeability of the fabric are recorded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com