Furnace tube structure of tungsten-molybdenum calcination or reduction rotary furnace

A technology of rotary furnace and furnace tube, which is applied in the direction of rotary drum furnace, furnace, furnace charge, etc., which can solve the problems of low yield of powder materials, large temperature difference of furnace tube, unstable product quality, etc., and achieve sufficient reaction and concentrated particle size distribution , the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

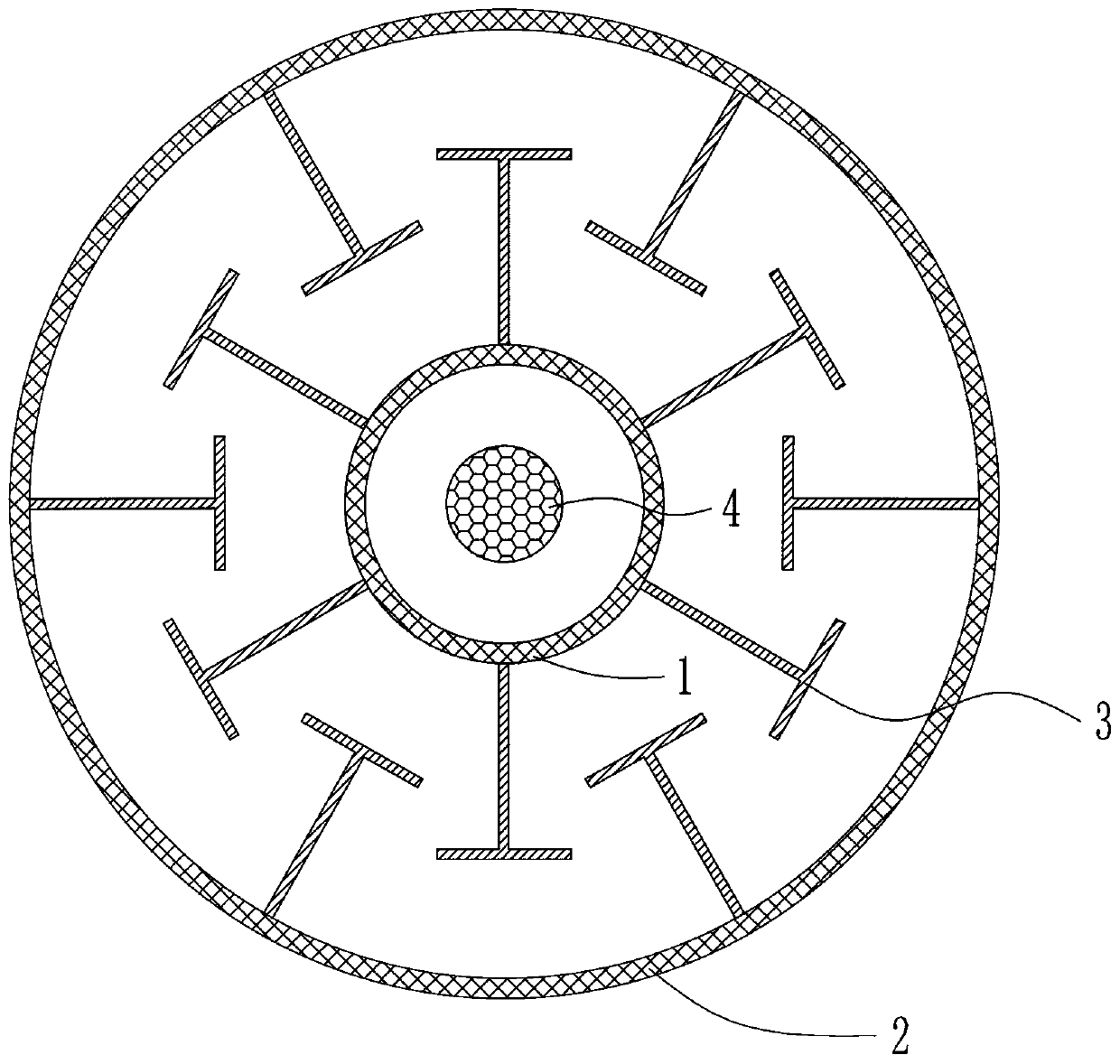

[0026] This specific embodiment is a rotary furnace for calcination or reduction of tungsten and molybdenum. The other components of the rotary furnace are consistent with the current structure, only the furnace tube structure is a non-current single-layer structure, but a double-layer coaxial hollow cylindrical structure. , the structure diagram of the furnace tube structure is shown in figure 1 As shown, and an electric heating device is also fixedly installed on the outer support of the double-layer furnace tube, the furnace tube structure includes an inner furnace tube wall and an outer furnace tube wall fixedly connected to each other, an inner furnace tube wall and an outer furnace tube wall The two can be fixedly connected by welding the fixed connecting rod, and the two ends between the inner furnace tube wall and the outer furnace tube wall are respectively connected and sealed by sealing plates, and a feed inlet is provided at one end. , with a discharge port at the ...

Embodiment 2

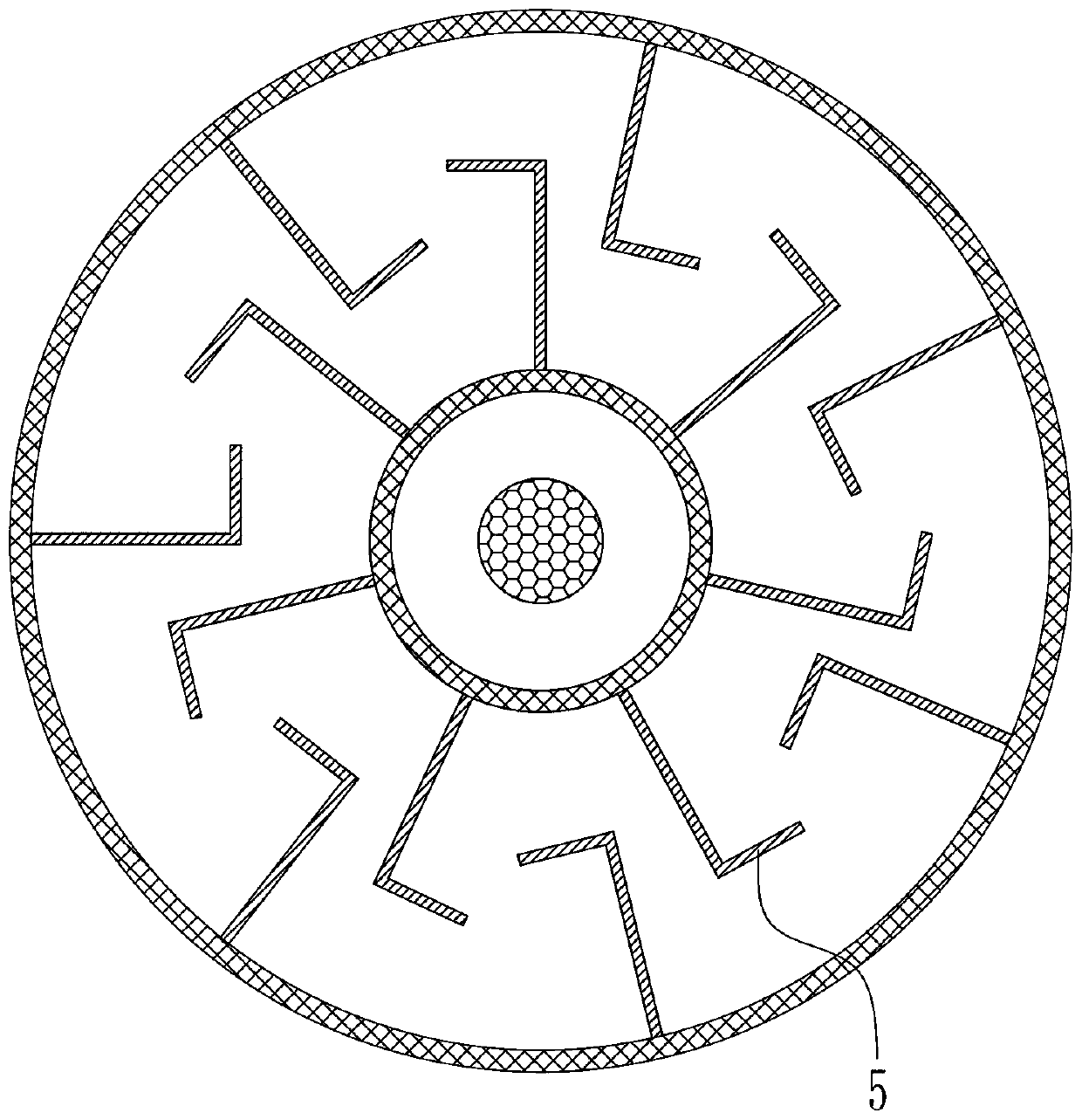

[0028] This specific embodiment is a rotary furnace for calcination or reduction of tungsten and molybdenum. The other components of the rotary furnace are consistent with the current structure, only the furnace tube structure is a non-current single-layer structure, but a double-layer coaxial hollow cylindrical structure. , the structure diagram of the furnace tube structure is shown in figure 2 As shown, and an electric heating device is also fixedly installed on the outer support of the double-layer furnace tube, the furnace tube structure includes an inner furnace tube wall and an outer furnace tube wall fixedly connected to each other, an inner furnace tube wall and an outer furnace tube wall The two can be fixedly connected by welding the fixed connecting rod, and the two ends between the inner furnace tube wall and the outer furnace tube wall are respectively connected and sealed by sealing plates, and a feed inlet is provided at one end. , with a discharge port at the...

Embodiment 3

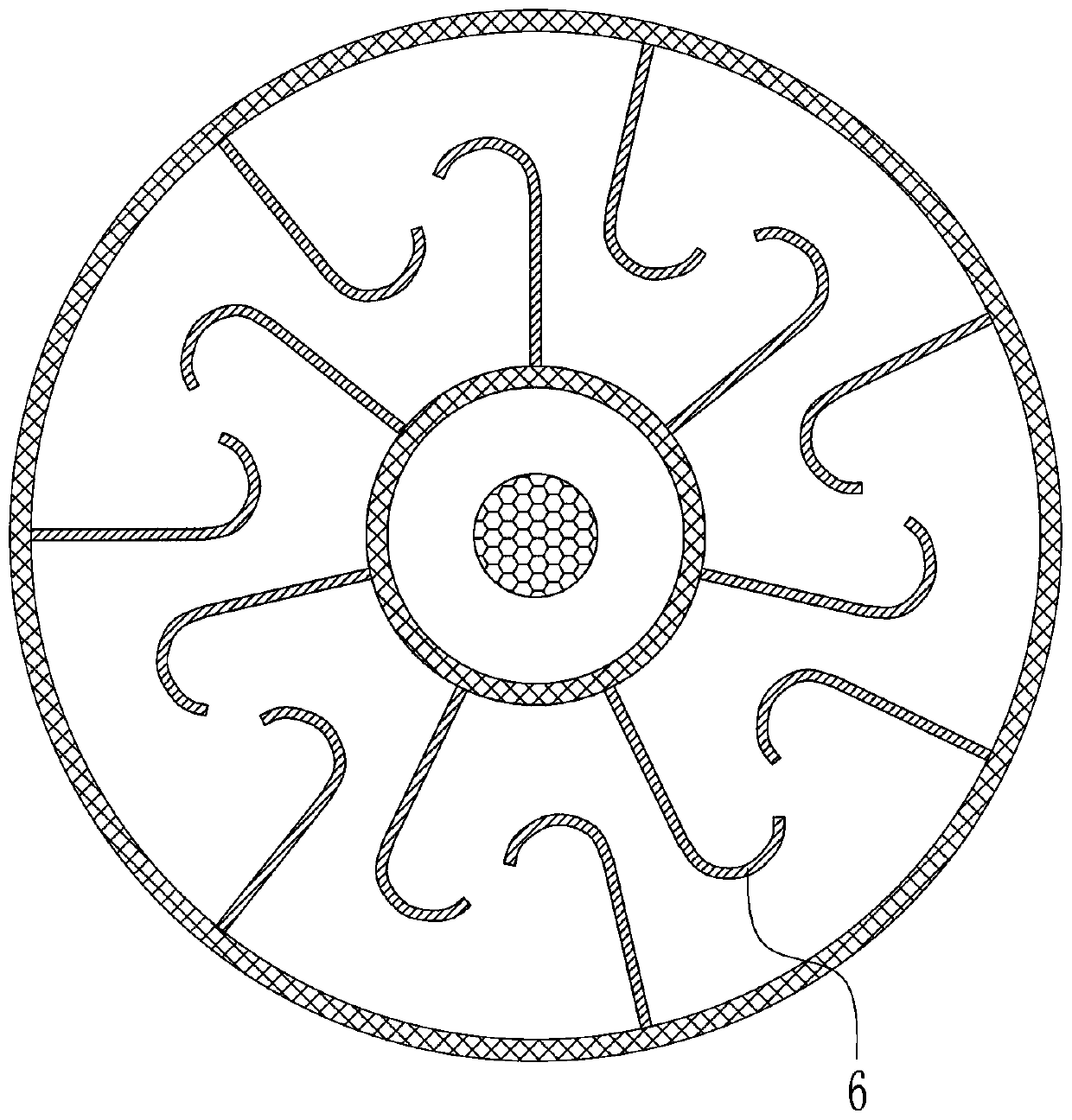

[0030] This specific embodiment is a rotary furnace for calcination or reduction of tungsten and molybdenum. The other components of the rotary furnace are consistent with the current structure, only the furnace tube structure is a non-current single-layer structure, but a double-layer coaxial hollow cylindrical structure. , the structure diagram of the furnace tube structure is shown in image 3 As shown, and an electric heating device is also fixedly installed on the outer support of the double-layer furnace tube, the furnace tube structure includes an inner furnace tube wall and an outer furnace tube wall fixedly connected to each other, an inner furnace tube wall and an outer furnace tube wall The two can be fixedly connected by welding the fixed connecting rod, and the two ends between the inner furnace tube wall and the outer furnace tube wall are respectively connected and sealed by sealing plates, and a feed inlet is provided at one end. , with a discharge port at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com