Cotton topping device and method for inhibiting cotton leaves from being damaged

A cotton and cotton leaf technology, applied in the field of cotton topping devices, can solve the problems of poor control accuracy, easy to overturn cotton, and unable to cut the top core, etc., and achieve the effects of satisfying instantaneous synchronization, reducing damage and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

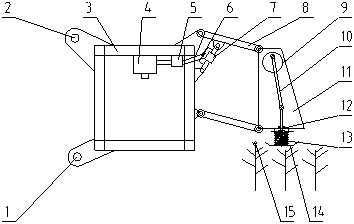

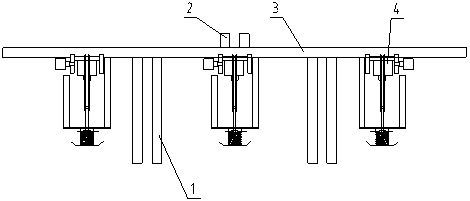

[0021] The cotton topping device that suppresses cotton leaves of the present embodiment, as figure 1 and figure 2 Shown, comprise: frame 3, the plant height perception mechanism that is arranged in frame 3, the topping mechanism that is arranged at frame 3 front ends; The topping mechanism is hinged with the frame 3; a hydraulic cylinder 7 is installed between the frame 3 and the parallel connecting rod 8; the hydraulic cylinder 7 can push the parallel connecting rod 8 to move, thereby changing the height of the topping mechanism; the plant height sensing mechanism is controlled by the imager 4 Composed of an ECU controller 5, the signal output end of the imager 4 is connected to the ECU controller 5, and the ECU controller 5 drives the hydraulic cylinder 7; the topping mechanism includes a topping support 11, and a crank 9 arranged on the topping support 11 1. One end is hinged with the connecting rod 10 of crank 9, and the beater assembly hinged with the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com