Crayfish dried meat floss and preparation method thereof

A technology of lobster and meat floss, which is applied to the functions of food ingredients, food ingredients as taste improvers, food science, etc. It can solve the problems of irregular shape bending, thin muscle fibers of shrimp meat, and irregular direction, etc., to achieve appropriate hardness and muscle fiber Loose and complete, "bite effect"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of crayfish floss, comprising:

[0027] A) pretreating the crayfish, and taking the crayfish meat;

[0028] B) extruding the crayfish meat with a rolling stick to obtain the extruded crayfish meat;

[0029] C) marinating the rolled crayfish meat with sugar, salt and papain, heat preservation and enzymolysis to obtain enzymolysis crayfish meat;

[0030] D) mixing the enzymatically hydrolyzed crayfish meat with water, and boiling to obtain the cooked crayfish meat;

[0031] E) seasoning the boiled crayfish meat, and then frying until there is no soup, to obtain the crayfish meat after the soup is collected;

[0032] F) Stir-fry the crayfish floss after collecting the soup, dry, cool, and pack to obtain the crayfish floss.

[0033] The invention provides a preparation method of crayfish floss. Firstly, the crayfish is pretreated to obtain the crayfish meat.

[0034] The present invention first selects crayfish, and th...

Embodiment 1

[0071] (1) Selection of crayfish: select fresh and live crayfish with uniform individual size and a single weight of 35-40 g from clean waters.

[0072] (2) Shrimp meat: Clean the crayfish, remove the head and thread, leave the belly and tail of the shrimp and blanch in boiling water for 15 seconds, then remove, immediately submerge in cold water, peel the shell and get the shrimp meat.

[0073] (3) Extrusion: The shrimp meat is passed through the extrusion machine with a roller gap of 5 mm and 3 mm in turn to make the shrimp meat flat.

[0074] (4) Enzymolysis: add 2.5% sugar, 1.5% salt, and 0.5U / g papain (hydrolyzed) to the extruded crayfish meat, mix well and place it at a constant temperature of 40-50°C 1h in the box.

[0075] (5) Cooking: Put the enzymatically hydrolyzed shrimp meat into 1.5 times cold water (the meat can be completely immersed in the water), boil for half an hour, then remove the meat for later use.

[0076] (6) Seasoning: According to the different fl...

Embodiment 2

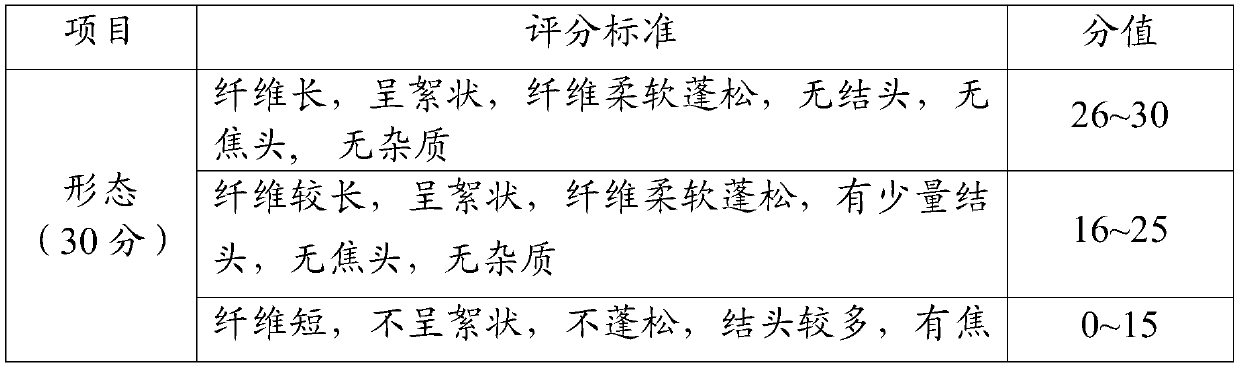

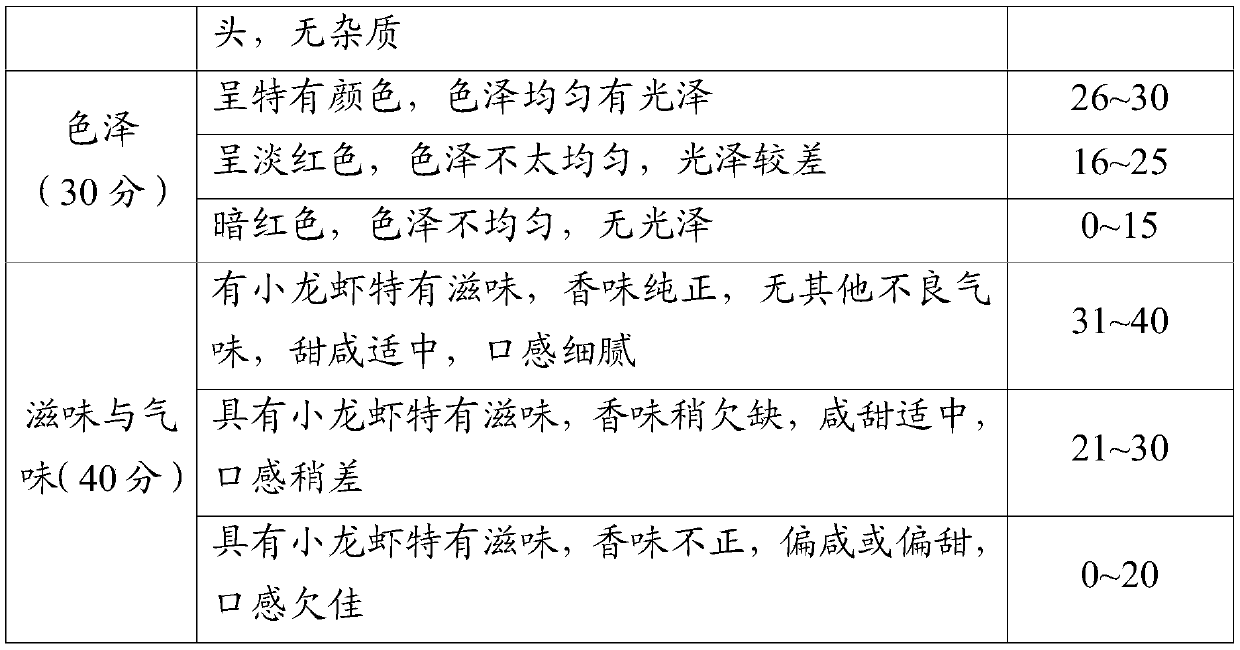

[0123] The crayfish floss sensory quality scoring method is guided by the "Guidelines for Sensory Analysis of Food Sensory Quality Control" (GB / T29605-2013), an appraisal team composed of 15 experienced food experts, and the crayfish prepared in this example and the comparative example The shape, color, taste and smell of meat floss are evaluated, and the weights of each index are 30 points, 30 points, 40 points, and the full score is 100 points. The average value of 15 experts' scores is taken as the scoring result. Scoring is based on the sensory evaluation criteria of crayfish floss in Table 1 (refer to GB / T23968-2009 meat floss).

[0124] The sensory evaluation standard of table 1 crayfish floss

[0125]

[0126]

[0127] Table 2 embodiment and comparative example crayfish floss sensory evaluation result

[0128] project form color taste and smell total score Example 29 28 39 96 Comparative example 1 20 23 25 68 Comparative ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com