Low-temperature solidified powder production line system and production process thereof

A technology of production process and production line, which is applied in the field of low-temperature curing powder production line system and its production process, and can solve problems such as production interruption, reduced production efficiency, and inability to realize continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

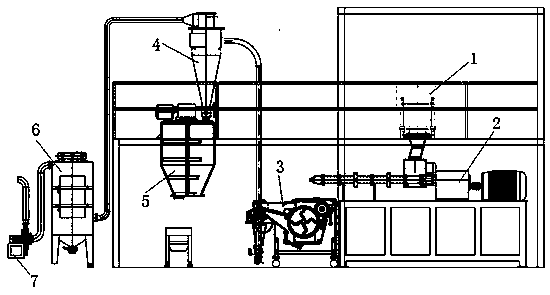

[0034] The low-temperature solidified powder production line system includes a mixer 1, a screw extruder 2, a roller tablet press 3, a cyclone separator 4 and a stirring tank 5 configured in sequence according to the production process route, wherein the mixer 1 has a mixing tank with ice The interlayer of the material tank connected to the water machine, the interlayer of the material tank is fed with ice water to control the mixing and stirring of the materials inside the material tank under the predetermined low temperature condition; the mixer 1 is sequentially connected to the screw extruder 2, and the screw extruder The outer screw sleeve and the inner mandrel of the extruder 2 are all connected to the ice water machine, and the ice water is fed to extrude the material at a low temperature. The screw length-to-diameter ratio of the screw extruder 2 is set to 30:1; The lower part of the discharge port of the screw extruder 2 is provided with a roller tablet press 3, and th...

Embodiment 2

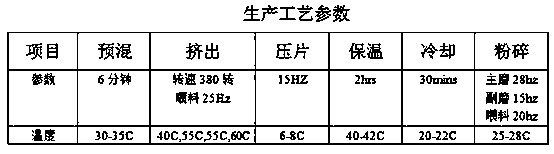

[0036] A production process for low-temperature solidified powder, which is implemented based on the production line system of Embodiment 1, includes the following specific steps:

[0037] S1, low temperature mixing

[0038] Put the material into the material tank of the mixer for pre-mixing, pass ice water into the interlayer of the material tank through the ice water machine, set the outlet water temperature of the ice water machine to 14 degrees, and the ice water in the material tank interlayer ensures that the materials in the tank are kept in the mixer Internal low-temperature mixing to reduce the frictional heat generated during the premixing process, the premixing time is controlled at 6 minutes, and the temperature of the material in the tank is 30-35 degrees at this time;

[0039] S2, low temperature extrusion

[0040] The premixed material enters the screw extruder, the screw length-to-diameter ratio of the screw extruder is 30:1, the extrusion speed is 380r / min, t...

Embodiment 3

[0052] A production process for low-temperature solidified powder, which is implemented based on the production line system of Embodiment 1, includes the following specific steps:

[0053] S1, low temperature mixing

[0054] Put the material into the material tank of the mixer for pre-mixing, pass ice water into the interlayer of the material tank through the ice water machine, set the outlet water temperature of the ice water machine to 12 degrees, and the ice water in the material tank interlayer ensures that the materials in the tank are kept in the mixer Internal low-temperature mixing to reduce the frictional heat generated during the premixing process, the premixing time is controlled at 8 minutes, and the temperature of the material in the tank is 28-32 degrees at this time;

[0055] S2, low temperature extrusion

[0056] The premixed material enters the screw extruder, the screw length-to-diameter ratio of the screw extruder is 30:1, the extrusion speed is 360r / min, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com