Pipeline intersecting line welding system

A welding system and intersecting line technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve redundant constraints, self-locking and other problems, achieve reduced equipment investment, strong operability, The effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

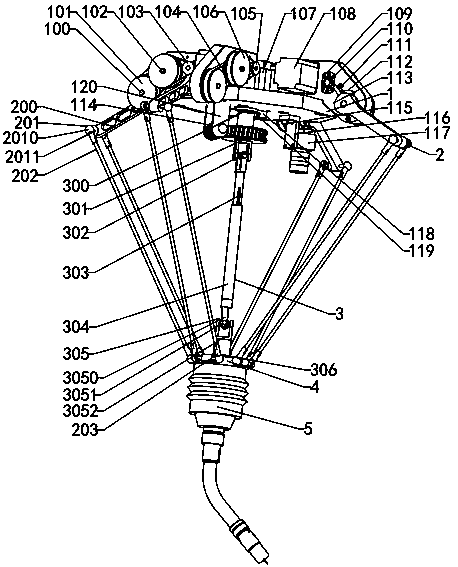

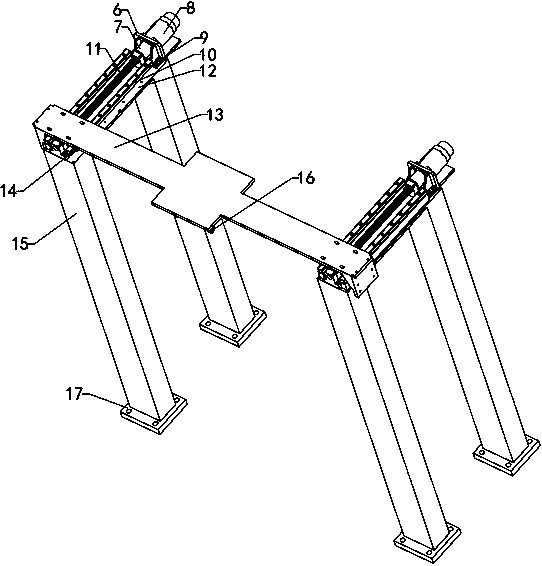

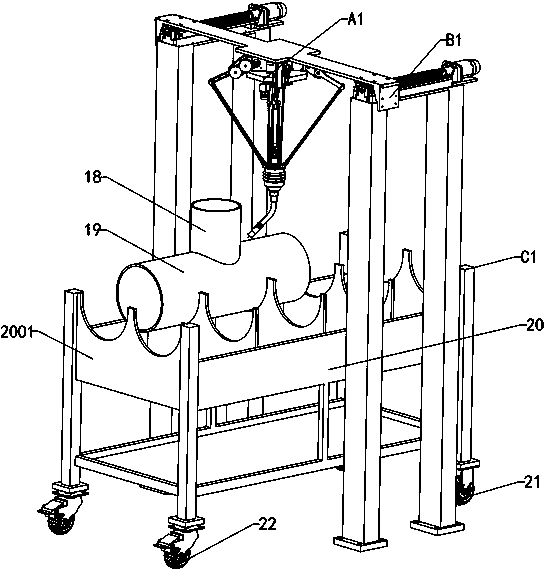

[0026] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~3 The present invention will be further described.

[0027] Refer to attached Figure 1~3 : A pipeline intersecting line welding system, including a parallel robot A1, an electric slide rail assembly B1 and a door-shaped bracket, the upper part of the door-shaped bracket is provided with an electric slide rail assembly B1, and the upper part of the parallel robot A1 is installed on the On the door-shaped bracket, the output end of the lower part of the parallel robot A1 is equipped with a welding torch 5; the parallel robot A1 includes a fixed platform 1, a moving branch chain 2, a central telescopic branch chain 3 and a moving workbench 4, and the fixed platform 1 and the moving workbench 4 are arranged in parallel up and down , Between the fixed platform 1 and the moving table 4, there are multiple sets of moving branch chains 2 and a set of central telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com