Flaky manganese dioxide as well as preparation method and application thereof

A manganese dioxide and flake technology, applied in the field of flake manganese dioxide and its preparation, can solve the problems of low activity and selectivity, limitations and the like, and achieve the advantages of simple operation in the preparation process, good catalytic performance, and good denitration activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Dissolve ammonium persulfate in 0.08M sodium hydroxide solution, add manganese nitrate dropwise under magnetic stirring (the molar ratio of manganese nitrate to ammonium persulfate is 2:3), react at room temperature for 15min, and the reaction product Carry out centrifugation, washing and drying in sequence to obtain the precursor; place the dried precursor in a muffle furnace to raise the temperature to 350°C at a rate of 1°C / min, and calcinate for 2 hours to obtain a flaky crystal structure of β phase manganese dioxide.

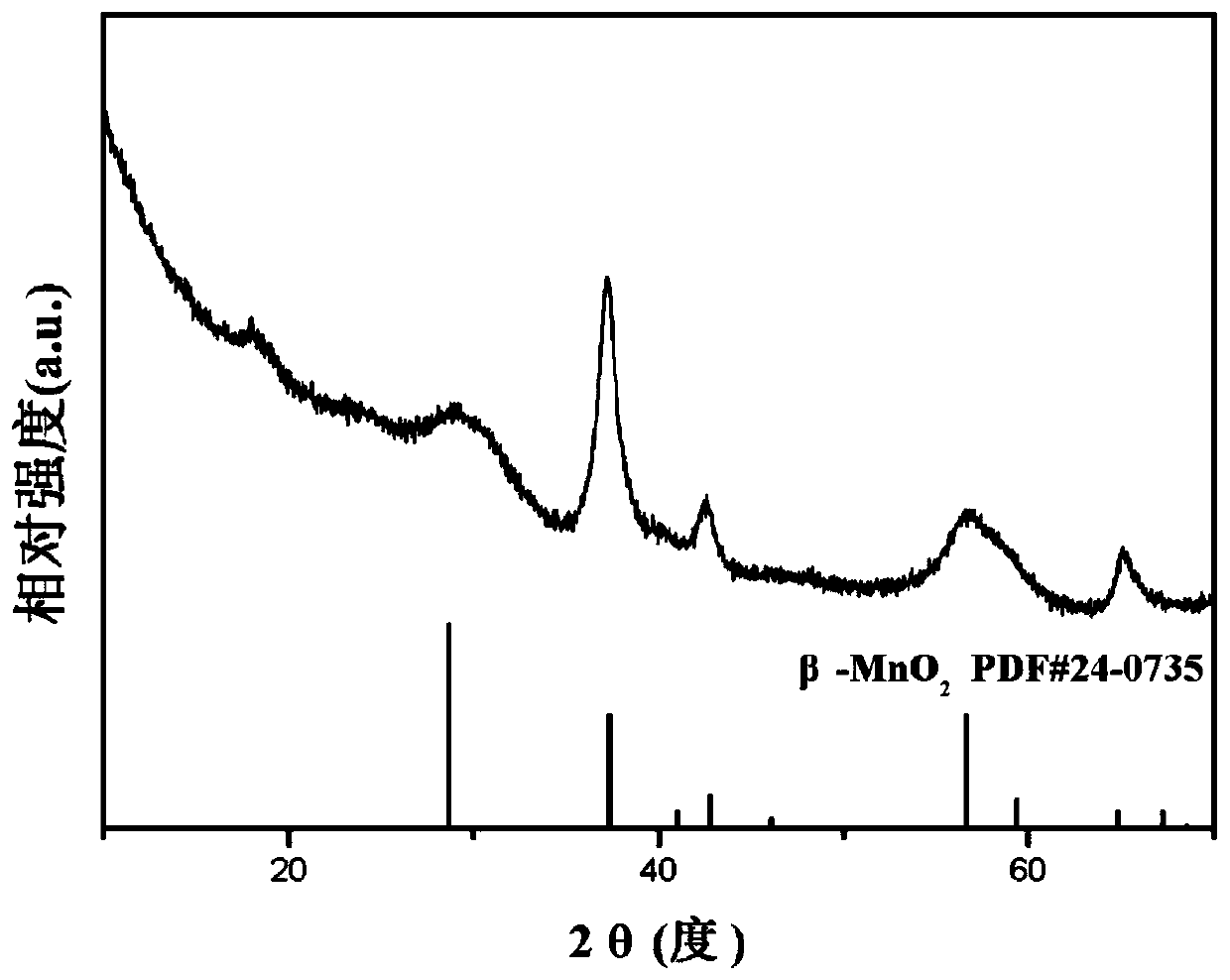

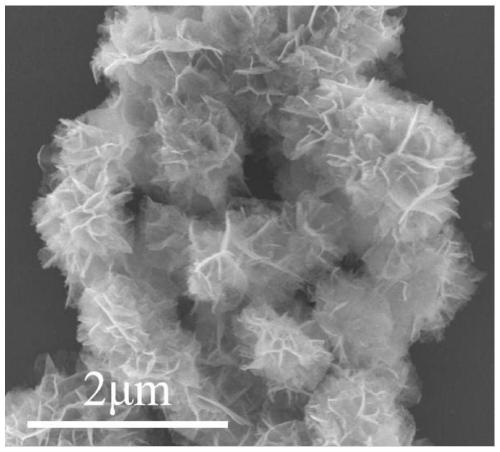

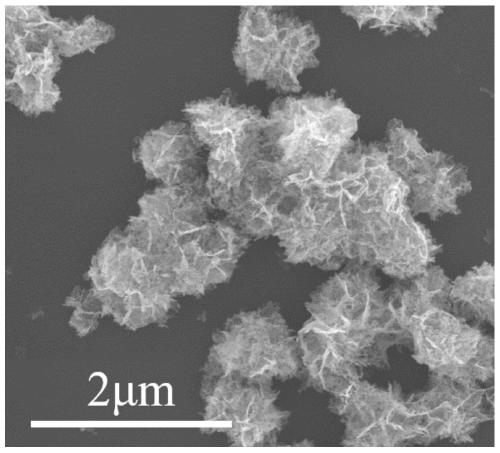

[0037] The flaky manganese dioxide prepared in the present embodiment is characterized, and its XRD spectrum is as follows figure 1 as shown, figure 1 Show that the β-MnO of present embodiment flake manganese dioxide and JCPDF standard card 24-0735 model 2 Correspondingly, it shows that the crystal structure of the flaky manganese dioxide in this example is the β phase. see figure 2 and image 3 , are respectively the SEM images of the precurso...

Embodiment 2

[0039] Dissolve ammonium persulfate in 0.08M sodium hydroxide solution, add manganese nitrate dropwise under magnetic stirring (the molar ratio of manganese nitrate to ammonium persulfate is 2:3), react at room temperature for 30min, and the reaction product Carry out centrifugation, washing and drying in sequence to obtain the precursor; place the dried precursor in a muffle furnace to raise the temperature to 350°C at a rate of 1°C / min, and calcinate for 2 hours to obtain a flaky crystal structure of β phase manganese dioxide.

Embodiment 3

[0041] Dissolve ammonium persulfate in 0.15M sodium hydroxide solution, add manganese nitrate dropwise under magnetic stirring (the molar ratio of manganese nitrate to ammonium persulfate is 2:3), react at room temperature for 60min, and the reaction product Carry out centrifugation, washing and drying in sequence to obtain the precursor; place the dried precursor in a muffle furnace to raise the temperature to 350°C at a rate of 1°C / min, and calcinate for 2 hours to obtain a flaky crystal structure of β phase manganese dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com