Lithium-sulfur battery diaphragm, preparation method thereof and lithium-sulfur battery

A lithium-sulfur battery and separator technology, applied in the lithium-sulfur battery separator and its preparation, and the field of lithium-sulfur batteries, can solve the problems of restricting the application of lithium-sulfur batteries, reducing battery energy density, unfavorable large-scale production, etc. The effect of low cost and improved cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

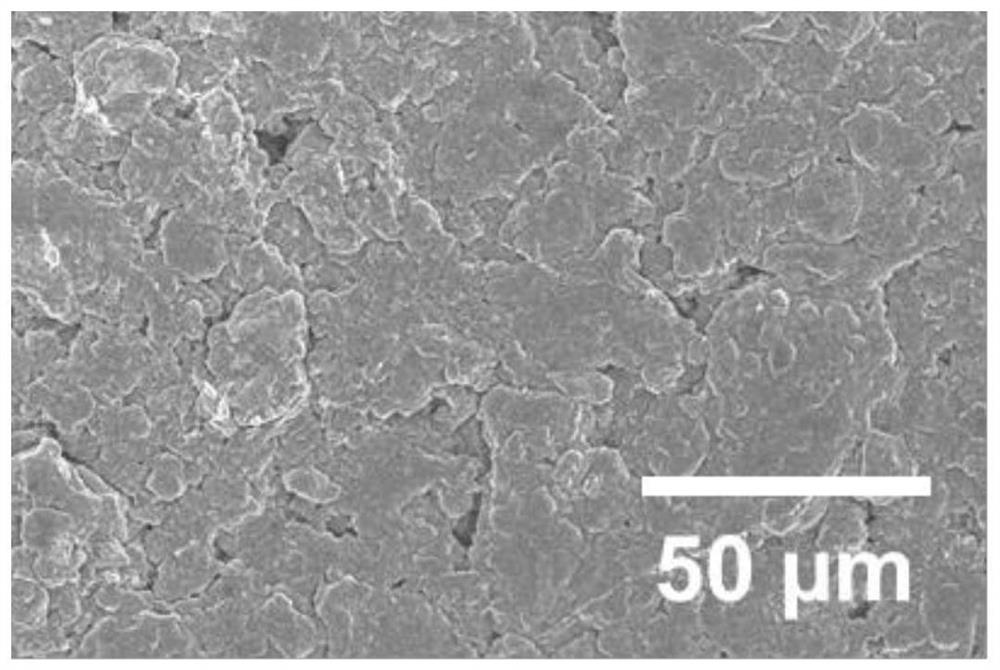

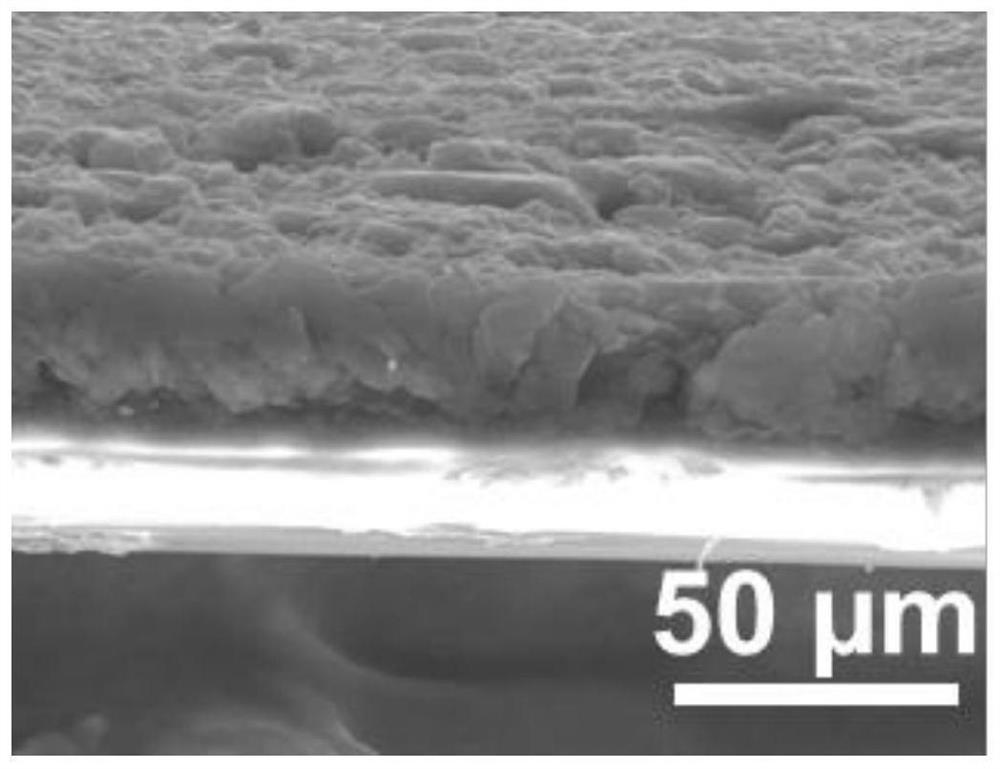

[0062] This embodiment provides a lithium-sulfur battery separator, the front SEM image of which is as follows figure 1 As shown, the cross-sectional SEM image is shown in figure 2 As shown, the lithium-sulfur battery diaphragm includes a diaphragm substrate and a diaphragm coating disposed on the surface of the diaphragm substrate, and the diaphragm coating includes Fe 3 o 4 / carbon nanotube / carbon fiber composite, PVDF and conductive carbon black, with the Fe 3 o 4 / The mass of carbon nanotubes / carbon fiber composites is 100%, the Fe 3 o 4 The content of carbon nanotubes is 60%, the content of carbon nanotubes is 35%, the content of carbon fibers is 5%, and the separator matrix is polypropylene separator (celgard 2500).

[0063] The preparation method of the lithium-sulfur battery separator described in this embodiment comprises the following steps:

[0064] (1) Dissolve ferric chloride and sodium oleate at a molar ratio of 1:2.9 in a mixed solvent of ethanol, d...

Embodiment 2

[0070] This embodiment provides a lithium-sulfur battery diaphragm, the lithium-sulfur battery diaphragm includes a diaphragm substrate and a diaphragm coating disposed on the surface of the diaphragm substrate, and the diaphragm coating includes Fe 3 o 4 / carbon nanotube / carbon fiber composite, PVDF and conductive carbon black, with the Fe 3 o 4 / The mass of carbon nanotubes / carbon fiber composites is 100%, the Fe 3 o 4 The content of carbon nanotubes is 70%, the content of carbon nanotubes is 25%, the content of carbon fibers is 5%, and the separator matrix is polypropylene separator (celgard 2500).

[0071] The preparation method of the lithium-sulfur battery separator described in this embodiment comprises the following steps:

[0072](1) Dissolve ferric chloride and sodium oleate at a molar ratio of 1:2.5 in a mixed solvent of ethanol, distilled water and n-hexane with a volume ratio of 4:3:7, put it into a magnetic rotor, and heat at 60°C And reflux for 6h, th...

Embodiment 3

[0077] This embodiment provides a lithium-sulfur battery diaphragm, the lithium-sulfur battery diaphragm includes a diaphragm substrate and a diaphragm coating disposed on the surface of the diaphragm substrate, and the diaphragm coating includes Fe 3 o 4 / carbon nanotube / carbon fiber composite, PVDF and conductive carbon black, with the Fe 3 o 4 / The mass of carbon nanotubes / carbon fiber composites is 100%, the Fe 3 o 4 The content of carbon nanotubes is 40%, the content of carbon nanotubes is 50%, the content of carbon fibers is 10%, and the separator matrix is polypropylene separator (celgard 2500).

[0078] The preparation method of the lithium-sulfur battery separator described in this embodiment comprises the following steps:

[0079] (1) Dissolve ferric chloride and sodium oleate in a molar ratio of 1:3 in a mixed solvent of ethanol, distilled water and n-hexane with a volume ratio of 4:3:7, put it into a magnetic rotor, and heat at 70°C And reflux for 3h, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com