High-hardness polyurethane elastomer and preparation method thereof

A polyurethane elastomer, high-hardness technology, applied in the field of materials, can solve the problems that the product cannot be produced and the process is not very mature, and achieve the effects of tensile strength and wear improvement, high bacteria resistance, and high hydrolysis resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

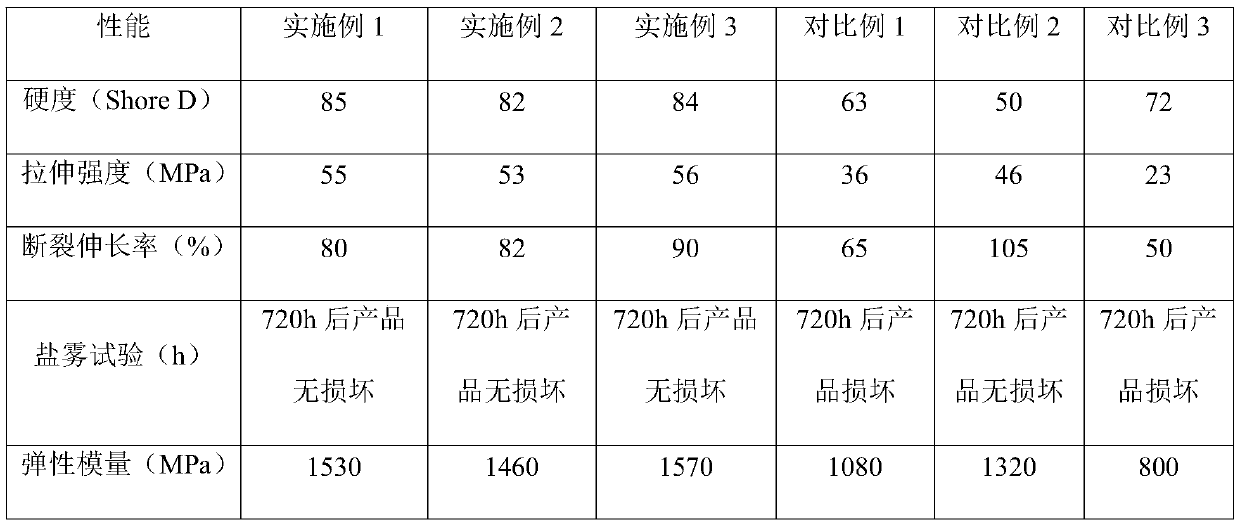

Examples

Embodiment 1

[0032] A component is a prepolymer component, including by weight:

[0033] Liquid MID50: 150 parts

[0034] Polycarbonate polyol: 80 parts

[0035] Polytetrahydrofuran polyol: 80 parts;

[0036] Component B is a polyol component, including by weight:

[0037] Polycarbonate polyol: 80 parts

[0038] Chain extender MOCA: 70 parts

[0039] Silicone surfactant: 0.3 parts

[0040] Color paste: 0.5 parts

[0041] Organotin catalyst: 0.3 parts

[0042] Toughener: 0.1 parts.

[0043] The preparation steps of high hardness polyurethane elastomer of the present invention comprise as follows:

[0044] (1) Preparation of component A: put polycarbonate polyol and polytetrahydrofuran polyol in a reaction kettle, first dehydrate and vacuumize at 115°C for 30 minutes, cool down to 55°C, add liquid MID50, first freely heat up and then keep warm for reaction 2- After 3 hours, control the content of NCO to be about 20% relative to component B, and discharge it, and keep it sealed for f...

Embodiment 2

[0048] A component is a prepolymer component, including by weight:

[0049] Liquid MID50: 100 parts

[0050] Polycarbonate polyol: 50 parts

[0051] Polytetrahydrofuran polyol: 50 parts;

[0052] Component B is a polyol component, including by weight:

[0053] Polycarbonate polyol: 50 parts

[0054] Chain extender MOCA: 60 parts

[0055] Silicone surfactant: 0.2 parts

[0056] Color paste: 0.2 parts

[0057] Organotin catalyst: 0.2 parts

[0058] Toughener: 0.1 parts.

[0059] The preparation steps of high hardness polyurethane elastomer of the present invention comprise as follows:

[0060] (1) Preparation of component A: put polycarbonate polyol and polytetrahydrofuran polyol in a reaction kettle, first dehydrate and vacuumize at 110°C for 40 minutes, cool down to 50°C, add liquid MID50, first freely heat up and then keep warm for reaction 2- After 3 hours, control the content of NCO to be about 20% relative to component B, and discharge it, and keep it sealed for f...

Embodiment 3

[0064] A component is a prepolymer component, including by weight:

[0065] Liquid MID50: 200 parts

[0066] Polycarbonate polyol: 100 parts

[0067] Polytetrahydrofuran polyol: 100 parts;

[0068] Component B is a polyol component, including by weight:

[0069] Polycarbonate polyol: 100 parts

[0070] Chain extender MOCA: 80 parts

[0071] Silicone surfactant: 0.5 parts

[0072] Color paste: 1 part

[0073] Organotin catalyst: 0.5 parts

[0074] Toughening agent: 0.2 parts.

[0075] The preparation steps of high hardness polyurethane elastomer of the present invention comprise as follows:

[0076] (1) Preparation of component A: put polycarbonate polyol and polytetrahydrofuran polyol in a reaction kettle, first dehydrate and vacuumize at 115°C for 40 minutes, cool down to 60°C, add liquid MID50, first freely heat up and then keep warm for reaction 2- After 3 hours, control the content of NCO to be about 20% relative to component B, and discharge it, and keep it sealed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com