Hot-dipping Zn-Al-Mg alloy coating layer steel plate and preparation method thereof

An alloy coating and hot-dip plating technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of difficult production, increased oxidation of the surface of the plating solution, and unfavorable production of zinc-aluminum-magnesium products, etc. To achieve the effect of good surface quality and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing the above-mentioned hot-dip Zn-Al-Mg alloy-coated steel sheet, which mainly includes the steps of degreasing cleaning, continuous annealing, hot-dip plating, air knife purging, cooling, skinning, surface treatment, and coiling.

[0031] Wherein, the degreasing cleaning mainly includes the steps of degreasing in the lye tank and the electrolytic tank, and then cleaning in the rinsing tank.

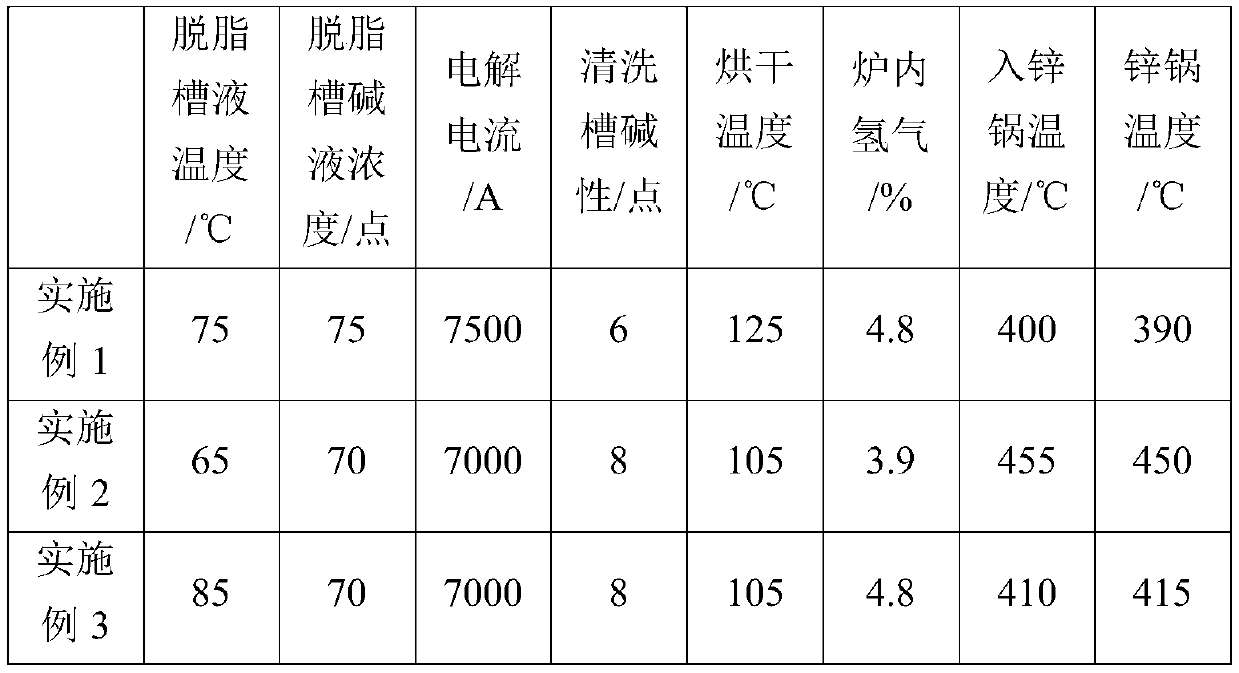

[0032] In order to effectively clean residues such as grease on the surface of the strip steel and the residual lye on the surface of the strip steel during the rinsing process, and to save production costs, the present invention can control the temperature of the lye in the lye tank to 60-90°C. The liquid concentration is controlled at 70-90 points, the electrolytic current of the electrolytic tank is controlled at 6000-8000A, the alkalinity of the rinsing tank is ≤8 points, and the drying temperature of the strip steel is ≥1...

Embodiment 1

[0048] The hot-dip Zn-Al-Mg alloy coated steel plate of the present embodiment has a coating weight of 80g / m 2 (double-sided), the main components of the coating are: aluminum 1.3%, magnesium 1.8%, lead 0.002%, antimony 0.002%, silicon 0.003%, tin 0.001%, and the rest is zinc.

[0049] The preparation method of the hot-dip Zn-Al-Mg alloy-coated steel plate in this embodiment is as follows: in the degreasing and cleaning process, the temperature of the bath solution needs to be controlled at 75°C, the concentration of the alkali solution in the degreasing tank is 75 points, the electrolytic current is 7500A, and the alkali solution in the cleaning tank is 6 points, the drying temperature of the strip is 125°C; in the continuous annealing process, the hydrogen in the furnace is 4.8%, and the temperature of the zinc pot is 400°C; in the hot dip plating process, the bath temperature is 390°C, and the bath composition is aluminum 1.3 %, magnesium 1.8%, the sum of unavoidable impuri...

Embodiment 2

[0052] The hot-dip Zn-Al-Mg alloy coated steel plate of the present embodiment has a coating weight of 100g / m 2 (double-sided), the main components of the coating are: aluminum 1.9%, magnesium 1.3%, lead 0.003%, antimony 0.002%, silicon 0.004%, tin 0.001%, and the rest is zinc.

[0053] The preparation method of the hot-dip Zn-Al-Mg alloy-coated steel plate in this embodiment is as follows: in the degreasing and cleaning process, the temperature of the bath solution needs to be controlled at 65°C, the concentration of the alkali solution in the degreasing tank is 70 points, the electrolytic current is 7000A, and the alkali solution in the cleaning tank is 8 points, the drying temperature of the strip is 105°C; in the continuous annealing process, the hydrogen in the furnace is 3.9%, and the temperature of the zinc pot is 455°C; %, magnesium 1.3%, the sum of unavoidable impurities 0.014%, of which lead 0.003%, antimony 0.002%, silicon 0.004%, tin 0.001%, and the rest is zinc; i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com