Slender pipe part single-piece independent power supply and flowing chromium plating device

An independent power supply, slender tube technology, applied in sealing devices, electrodes, electrolysis processes, etc., can solve the influence of the thickness uniformity of the chrome plating layer on the inner wall of the deep and small holes of the slender tube, the uneven thickness distribution of the chrome layer, and the difficulty of replenishing the electrolyte in time. and other problems, to achieve the effect of improving processing quality and performance, high economic benefits and social value, and improving current uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

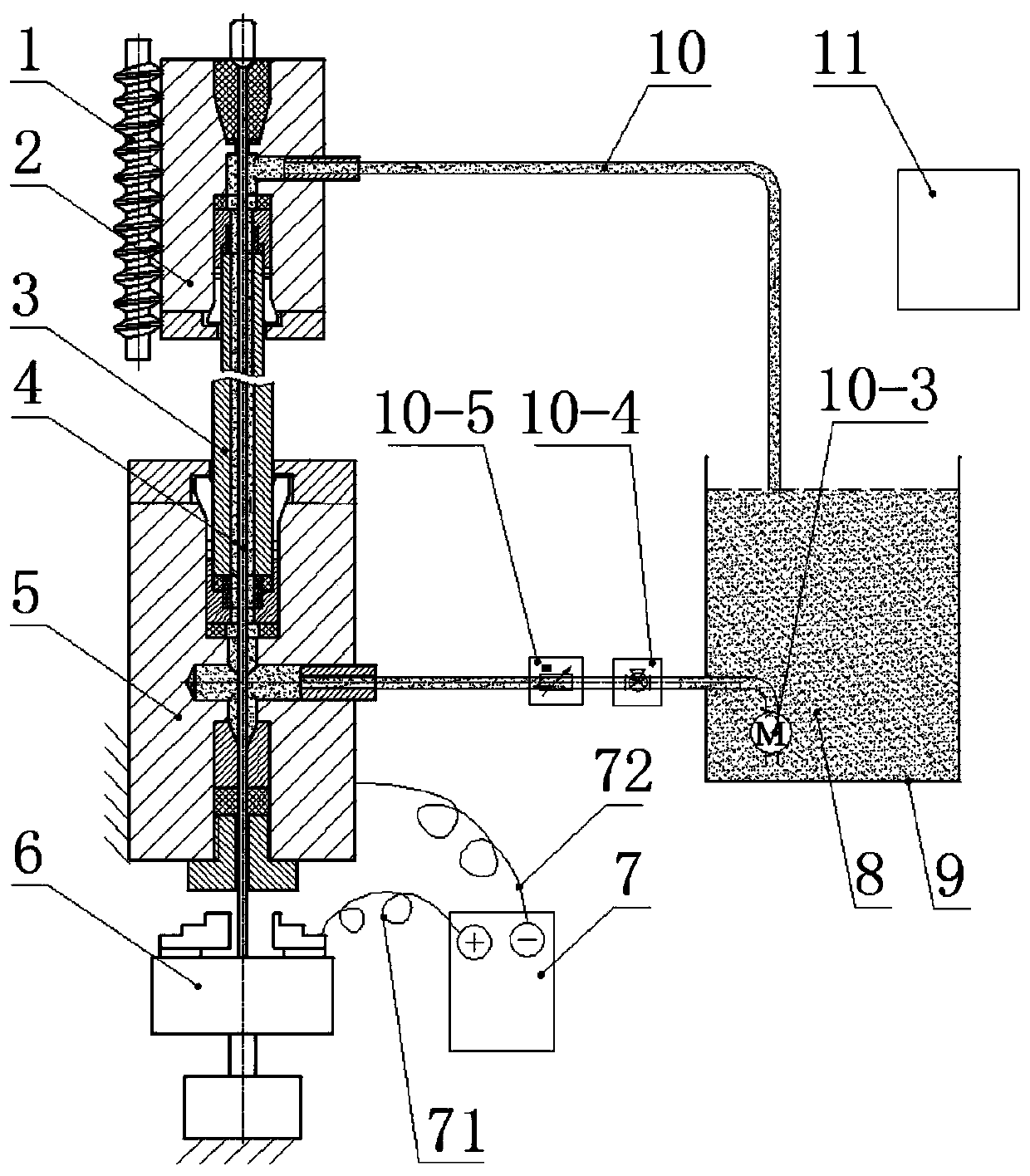

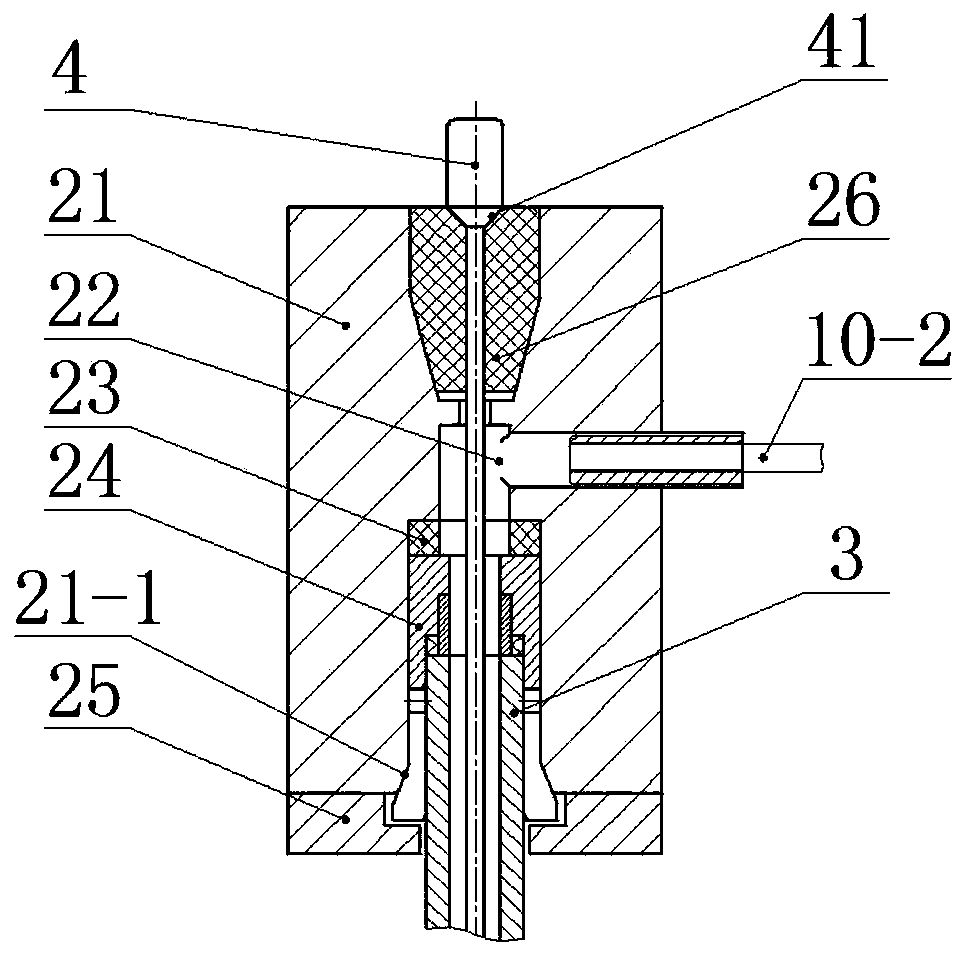

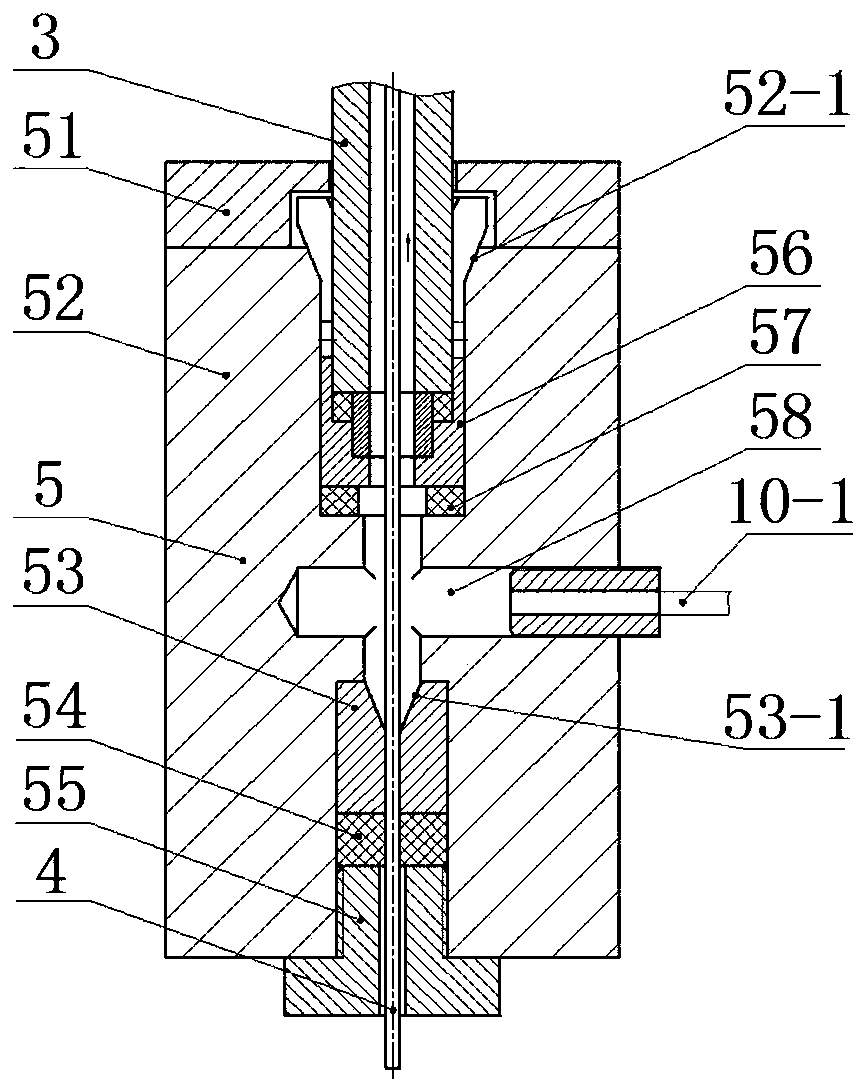

[0042] see Figure 1-Figure 5 , a slender tube part is equipped with an independent power supply and a mobile chrome plating device, which is used to chrome-plate the inner wall of the deep hole of the slender tube, including an upper bracket 2 and a lower bracket 5, and the upper bracket 2 and the lower bracket 5 are vertically To place, the slender tube 3 is clamped between the upper bracket 2 and the lower bracket 5, and the central hole of the upper bracket 2, the lower bracket 5 and the slender tube 3 is pierced with an anode steel wire 4. During chrome plating, the upper bracket 2 and the lower bracket 5 are respectively installed together with the two ends of the slender tube 3 through hole shaft cooperation to ensure that the slender tube 3 is clamped on the chrome plating device and placed in a vertical state, so that the electroplatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com