Pulping machine millstone, pulping machine rotor and pulping machine with pulping machine millstone

A technology of a refiner and a grinding disc, applied in pulp beating/refining methods, electromechanical devices, control of mechanical energy, etc., to achieve low energy consumption, reduce downtime and no-load power, and stabilize the effect of refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

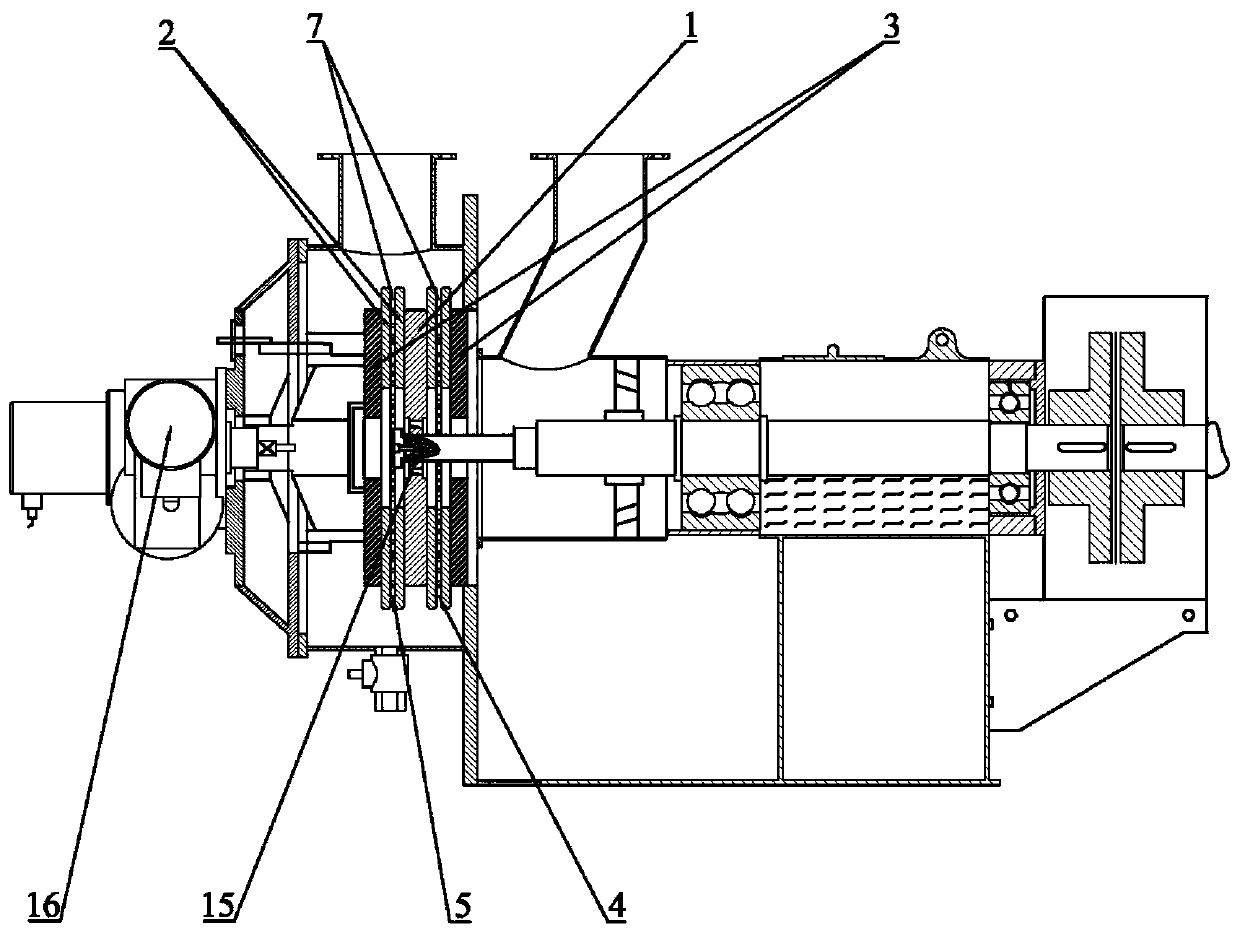

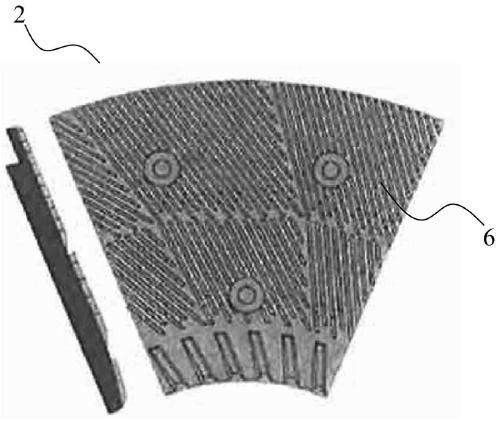

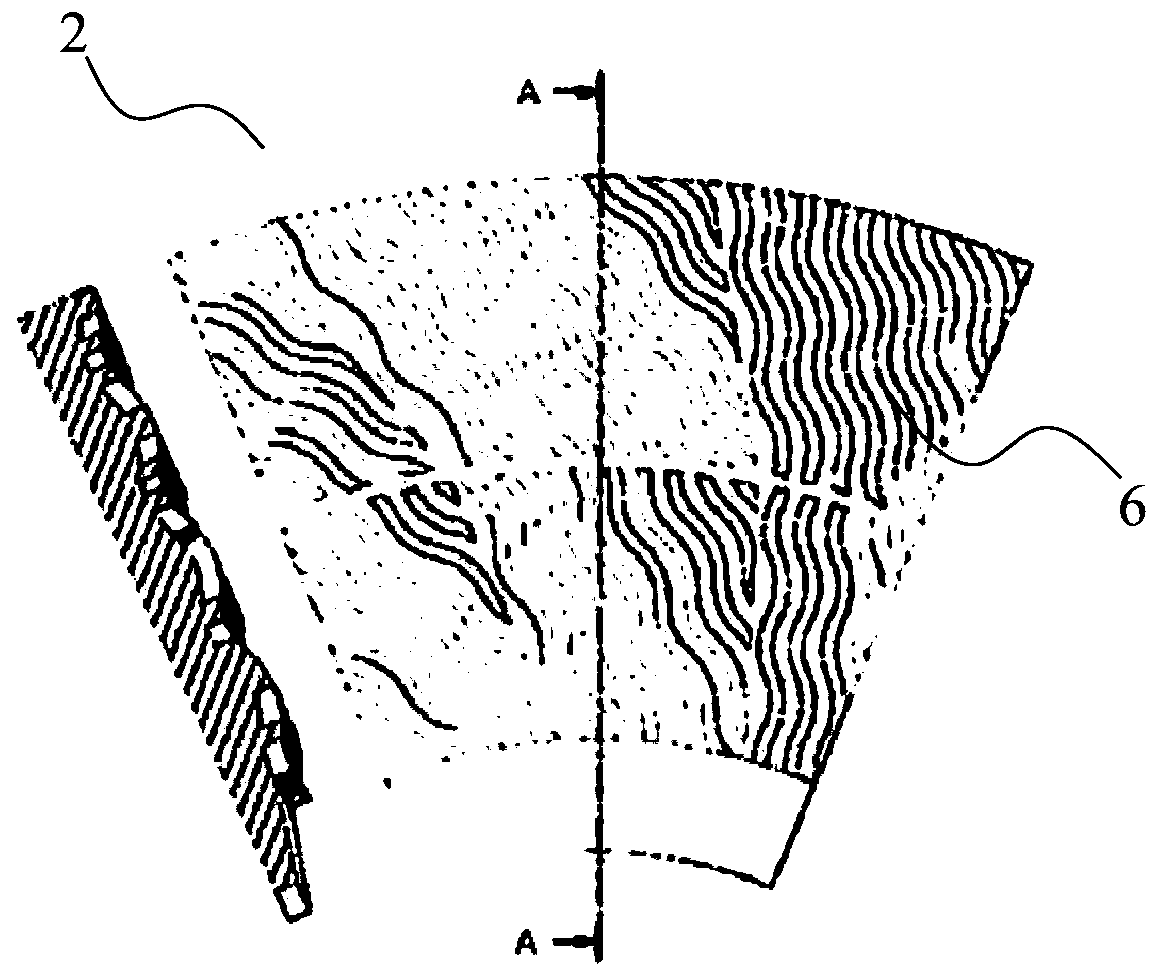

[0023] According to a first embodiment of the invention, at least part of the sharpening edge of the refiner plate is designed to be undulating in the radial direction, and at least part of the sharpening edge of the refiner plate is designed to be undulating in the axial direction. Wherein, the wavy degree of the grinding blade of the refiner disc in the radial direction gradually increases from the slurry inlet side at the center of the disc to the slurry outlet side at the outer periphery of the disc. Preferably, the ratio of the wavy degree of the sharpening edge of the refiner grinding disc in the radial direction between the slurry inlet side at the center of the grinding disc and the slurry outlet side at the outer periphery of the grinding disc is between 1:1.15 and 1:1.45.

[0024] According to a second embodiment of the invention, at least part of the sharpening edge of the refiner plate is designed to be undulating in the radial direction, and at least part of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com