Method for monitoring external water pressure of lining

A water pressure and lining technology, applied in the measurement of fluid pressure, drilling equipment and methods, measurement, etc., can solve the problems of affecting the bearing capacity of the tunnel lining, the waterproof performance of the tunnel, the adverse effect of the safety of the tunnel operation, and the inability to predict the various conditions of the tunnel. , to achieve the effect of no impact on the construction period, reasonable layout of monitoring points, and reduction of the number of layouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

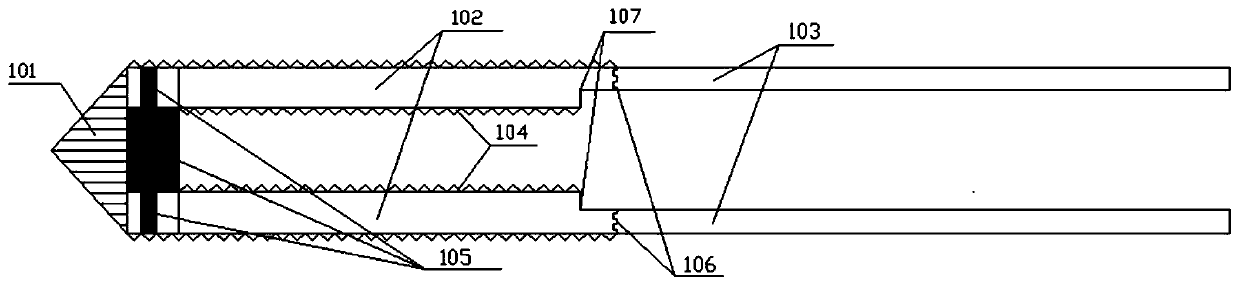

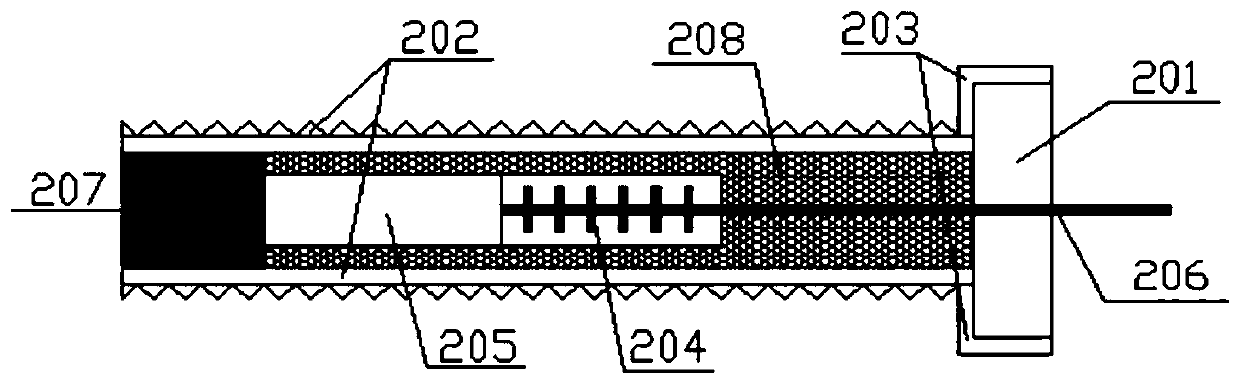

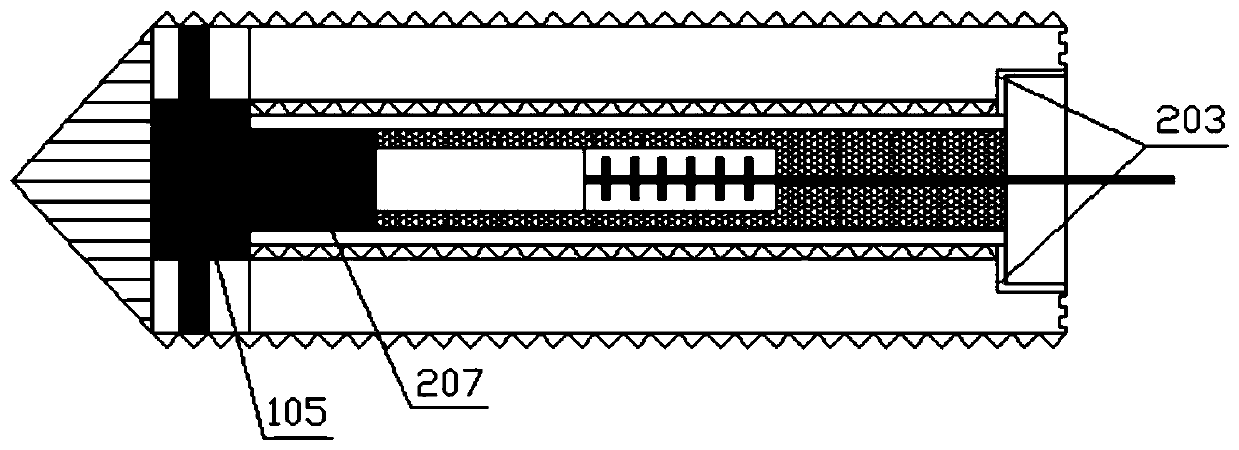

[0042] like Figure 5 As shown, the present invention realizes the external water pressure monitoring of the tunnel during the operation period by drilling and installing a piezometer in the tunnel lining during the operation period, including the following steps:

[0043] 1) Use manual or vehicle-mounted detection technology to detect water leakage in operational tunnels, collect groundwater distribution data revealed during the construction period, and determine water pressure monitoring areas and sections;

[0044] 2) Use total stations, laser scanners or convergent gauges to detect tunnel deformation, compare it with the deformation data at the initial stage of tunnel operation, determine the distribution characteristics and values of water pressure behind the lining by back analysis, and preliminarily determine that the water pressure values are relatively low. Larger locations, and determine the measuring range of the instrument according to 2 to 3 times the external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com