Non-contact infrared temperature measurement system based on square battery and test method

A prismatic battery, non-contact technology, used in radiation pyrometry, measuring electricity, measuring devices, etc., can solve the problems of long response time, easy to be affected by ambient temperature, etc., to achieve fast response speed, good stability, The effect of high temperature resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The non-contact infrared temperature measurement system based on a square battery according to the present invention includes:

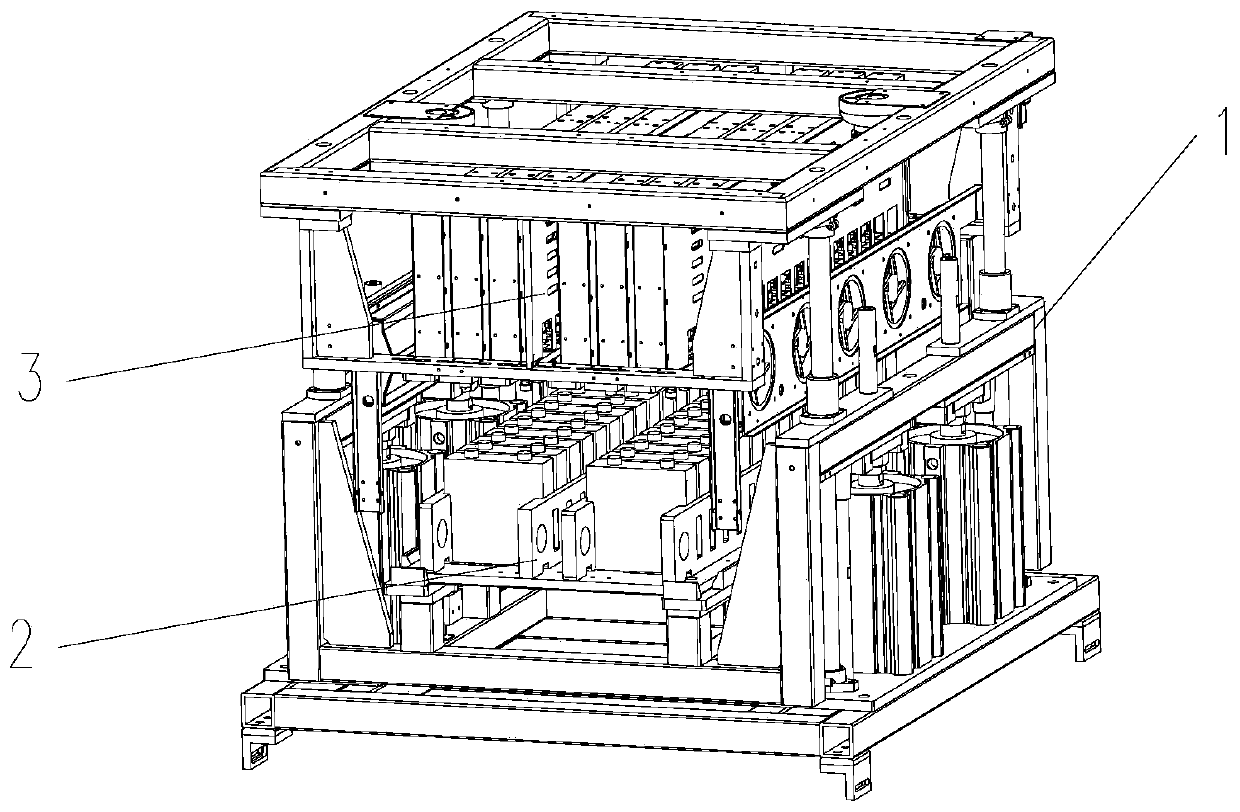

[0034] The frame 1 has an installation cavity for installing the battery tray assembly 2 and the infrared temperature detection assembly 3;

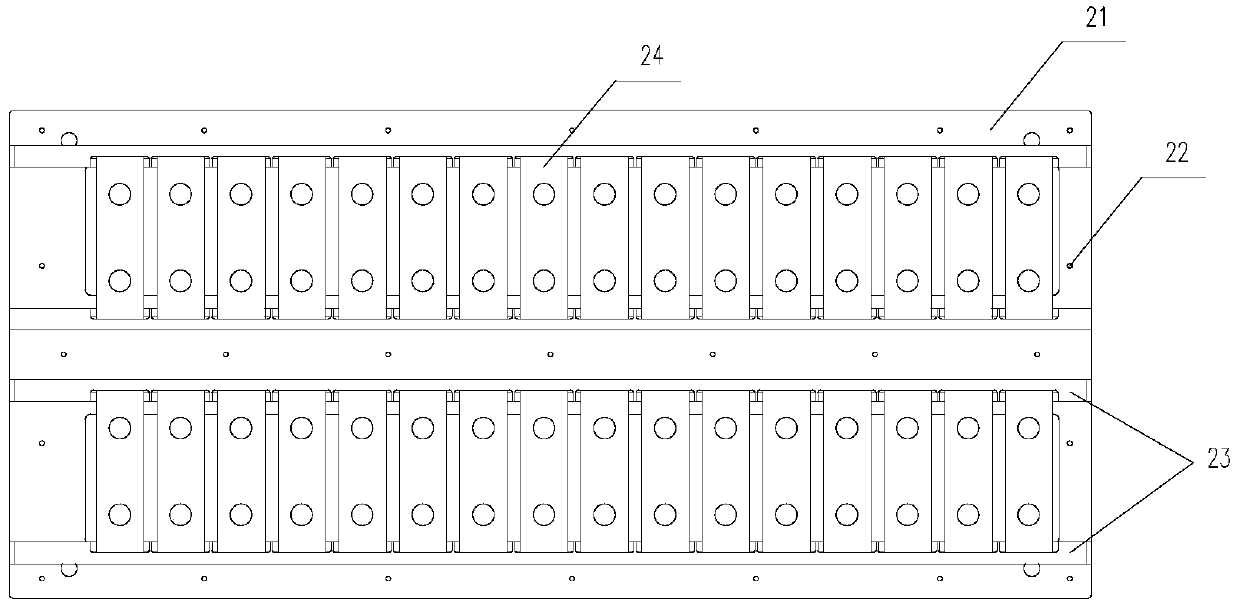

[0035] The battery tray assembly 2 is arranged at the bottom of the installation cavity of the frame 1, and the battery tray assembly is provided with a battery placement area for holding a square lithium battery 24;

[0036] The infrared temperature detection assembly 3 is installed on the top of the rack installation cavity, including the needle plate structure 31, the structure fixing module 32, the acquisition module 33 and the slave module 34, and the needle plate structure 31 is installed with the slave module 34, The bottom is installed on the upper part of the installation cavity through the structural member fixing module 32; the acquisition module 33 is arranged on the structural m...

Embodiment 2

[0044] Embodiment 2 A non-contact infrared temperature measurement system for a square battery according to the present invention is characterized in that,

[0045] The frame 1 is a support component, which is used to support the installed non-contact infrared temperature measurement component.

[0046] The battery tray assembly 2 is used to hold a square lithium battery 24 .

[0047] The infrared temperature detection assembly 3 is used to collect the temperature of the surface of the square lithium battery and execute the control command transmitted by the communication module 4 .

[0048] The communication module 4 is used for transmitting the temperature detection signal of the infrared temperature detection assembly 3 and performing debugging and debugging. At the same time, the control command of the output module 5 is also being transmitted.

[0049] The output module 5 obtains the data of the communication module 4 to output the battery temperature, and can also be u...

Embodiment 3

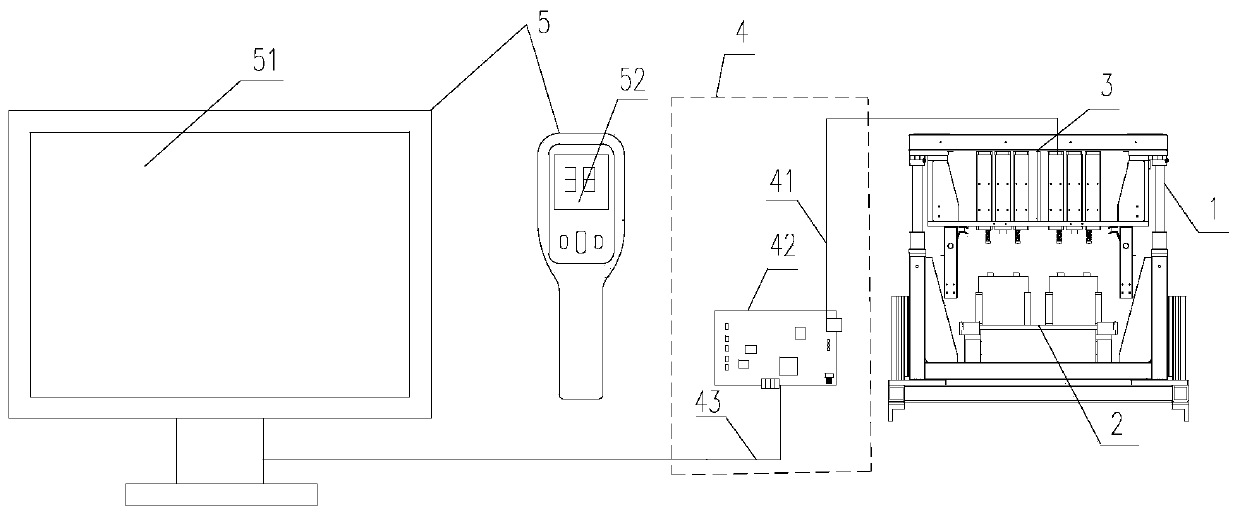

[0064] Embodiment 3 The difference between this embodiment and Embodiment 2 is that, from Figure 1a , 1b It can be seen that the non-contact infrared temperature measurement system for a square battery is composed of a frame 1 , a battery tray assembly 2 , an infrared temperature detection assembly 3 , a communication module 4 and an output module 5 . Rack 1 is a support component; battery tray assembly 2 is used to hold a square lithium battery 24; battery tray 2 is placed under the rack 1 during testing; the infrared temperature detection assembly 3 is above the rack 1, and the infrared ray The temperature detection assembly 3 is located directly above the battery tray assembly 2; the communication module 4 includes a CAN bus module 41, a host module 42 and an Ethernet module 43; the communication module 4 and the slave module of the infrared temperature detection assembly 3 34 is electrically connected through the CAN bus module 41; the output module 5 is located next to t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap