Laser ultrasonic system and method for detecting thermal diffusivity of nano-film in non-contact manner

A thermal diffusivity, nano-film technology, applied in the analysis of solids, measuring devices, and material thermal development using sonic/ultrasonic/infrasonic waves. Accurate information and accurate thermal diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

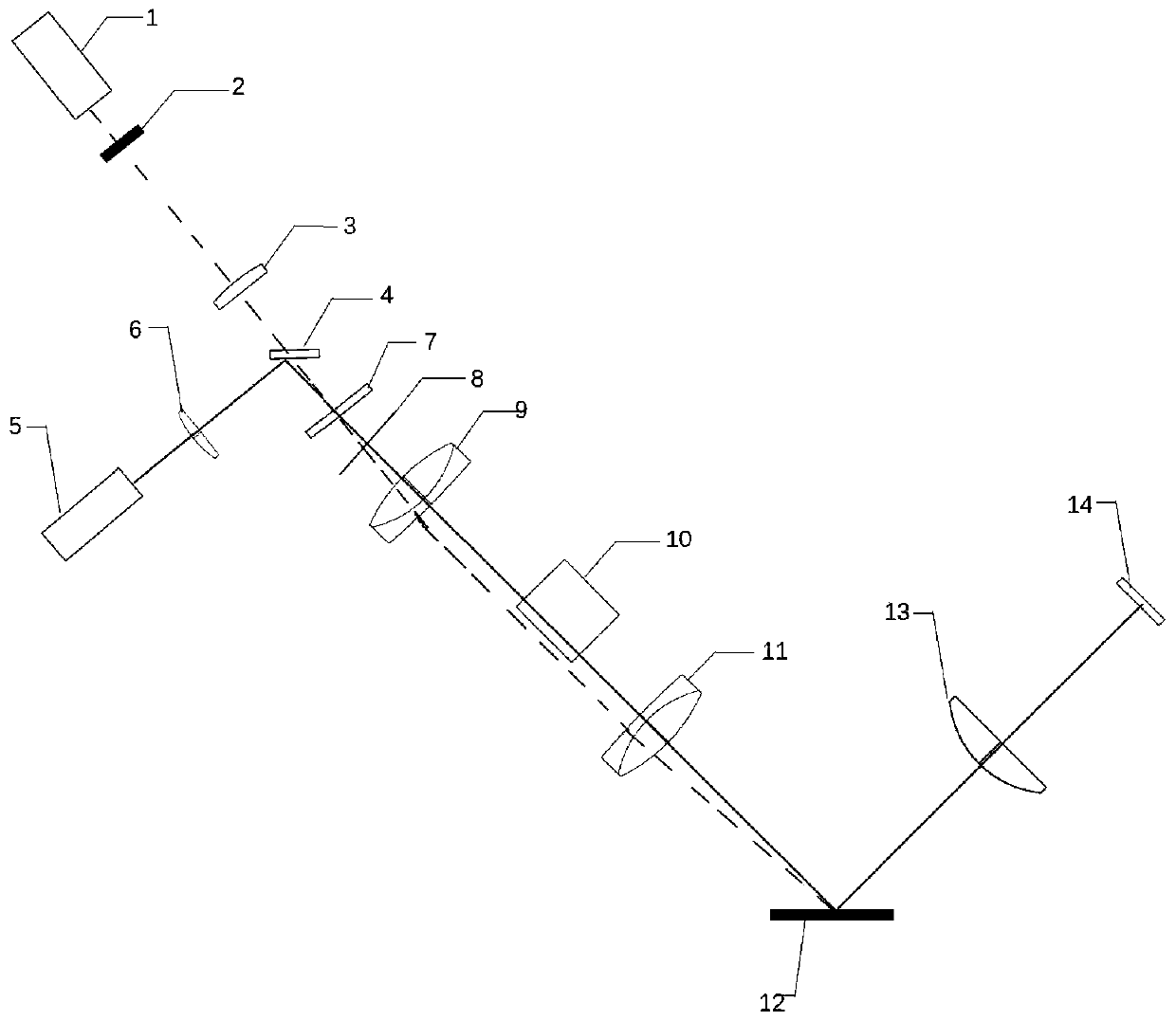

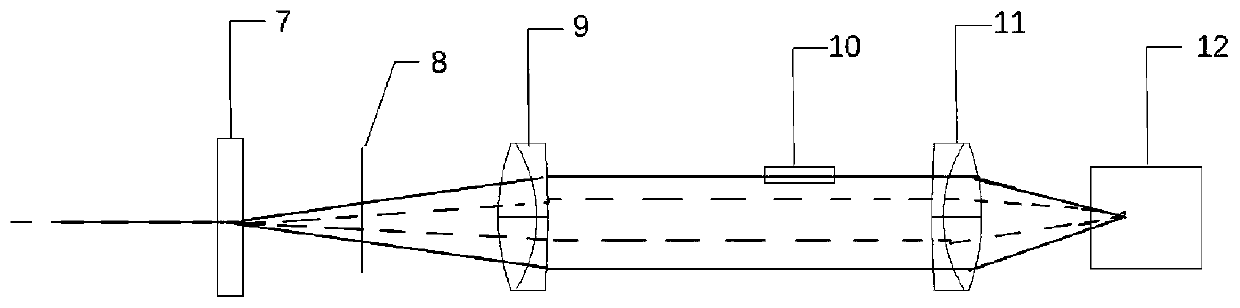

[0047] Such as figure 1 , 2 As shown, a laser ultrasonic system for non-contact detection of thermal diffusivity of nano-films, including an excitation light emission module, a detection light emission module, a dichroic mirror 4, a phase mask 7, a shutter 8, and a first achromatic lens 9. The phase adjuster 10, the second achromatic lens 11, the moving sample stage and the signal receiving module are set to:

[0048] The excitation light emitted by the excitation light emission module is transmitted through the dichroic mirror 4 and then focused to the phase mask 7. The phase mask 7 divides the excitation light into two beams, and the two beams of excitation light pass through the shutter 8 and the first achromatic lens in sequence. 9. The second achromatic lens 11 focuses on the sample surface set on the moving sample stage;

[0049] The detection light emitted by the detection light emitting module is reflected by the dichroic mirror 4 and then focused to the phase mask 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com