3D radar scanner for blast furnace charge level imaging and blast furnace charge level inspection system

A blast furnace material level and radar scanning technology, which is applied in the direction of radio wave measurement system, liquid level indicator, instrument, etc., can solve the problems of uneven distribution of material level, poor effect in low temperature area, inability to traverse the blast furnace material level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

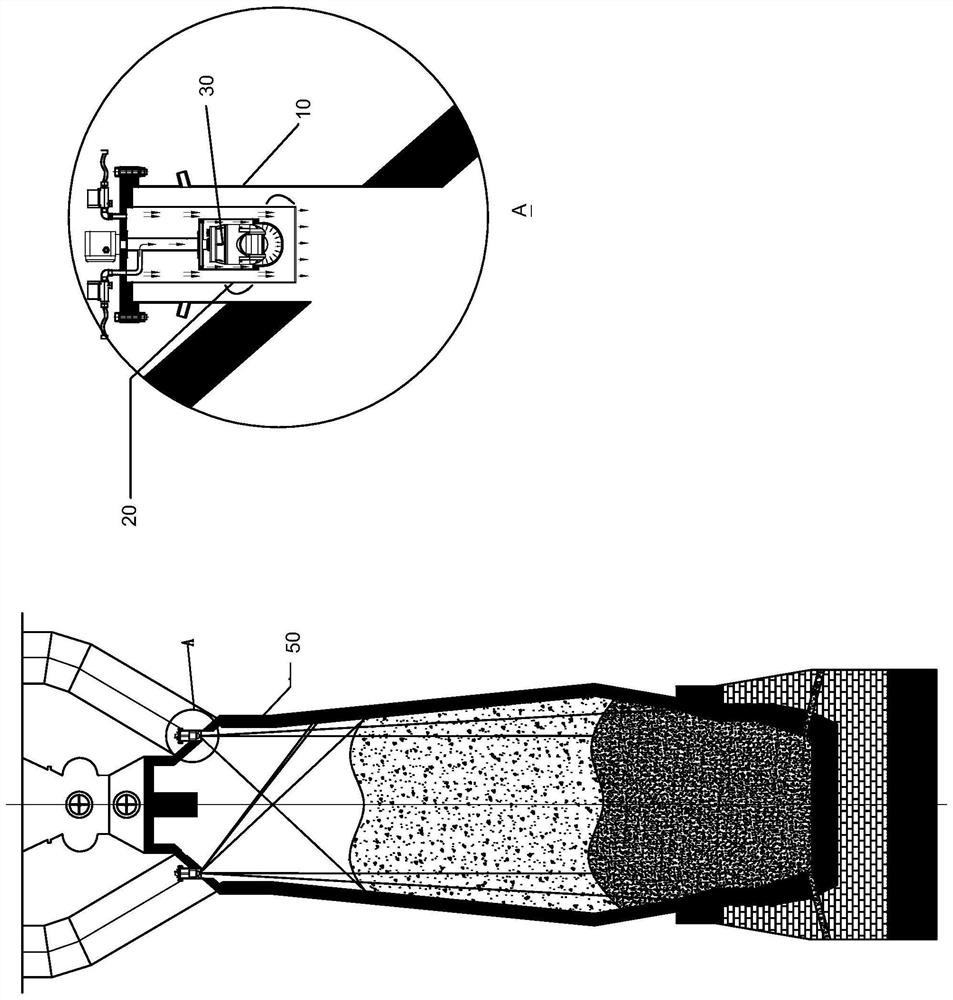

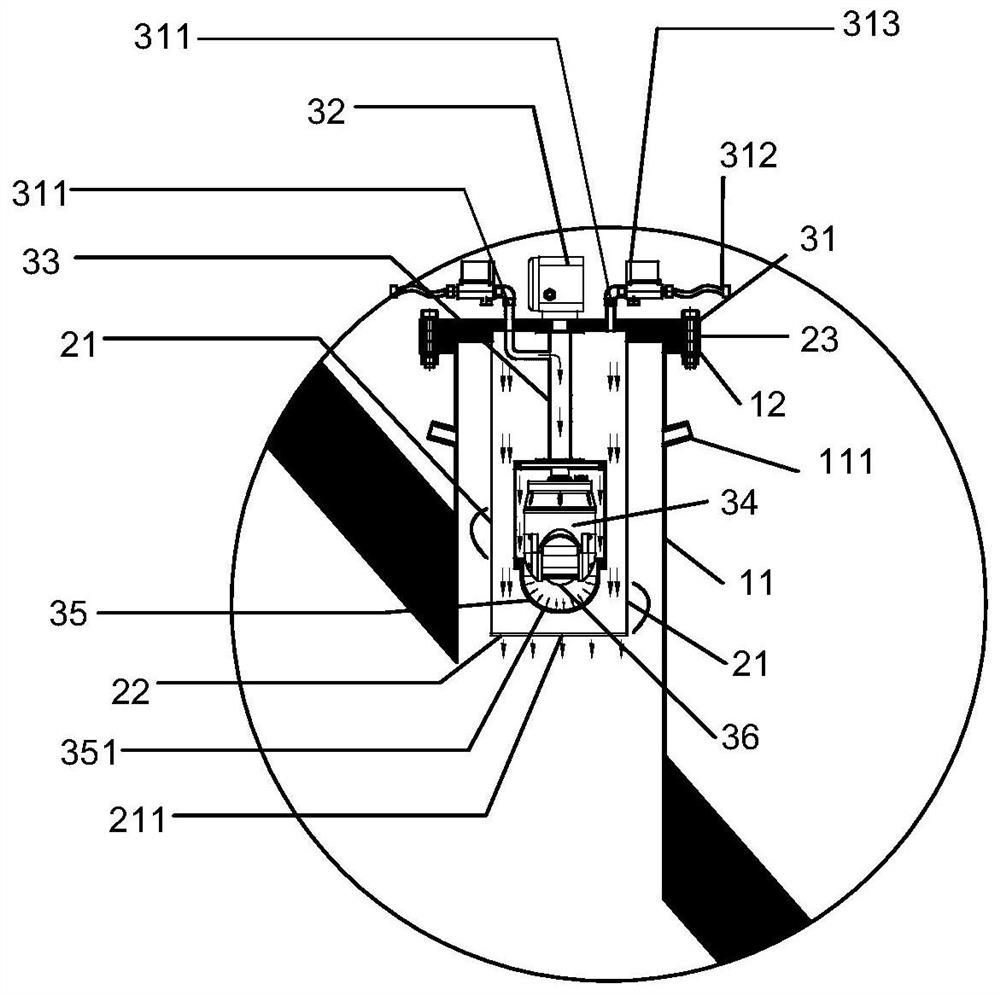

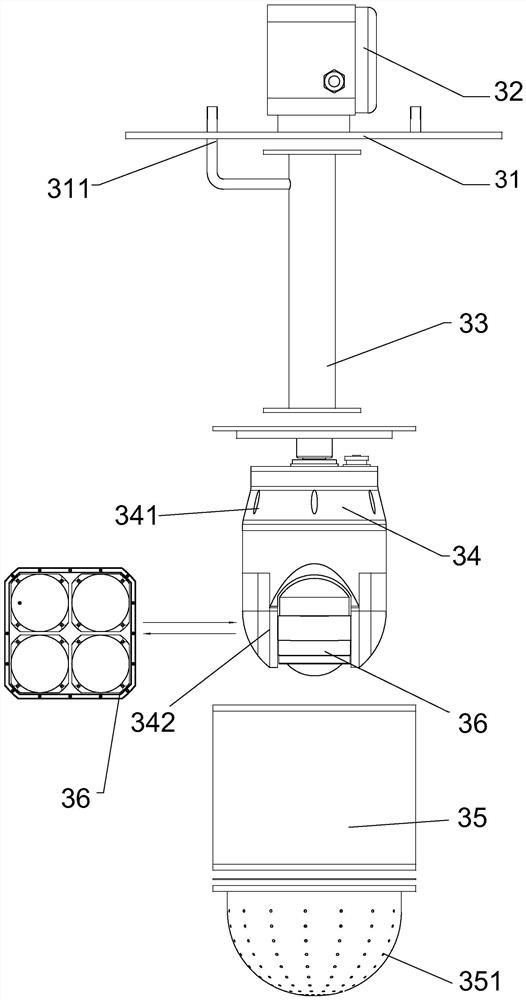

[0033] See attached figure 1 with 2 , figure 1 with 2 The main structure of a 3D radar scanner used for blast furnace charge level imaging is shown as an example, such as figure 1As shown, the 3D radar scanner 100 for blast furnace material surface imaging provided by the present invention may include: a base component 10 installed on the top of a blast furnace 50 , a high temperature isolation cover component 20 and a multi-dimensional radar component 30 . The base component 10 includes a base protection tube 11 and a base flange 12. One end of the base protection tube 11 communicates with the blast furnace 50, and the other end is fixedly connected to the base flange 12. The base protection tube 11 is provided with at least one first inlet Air port 111. The high-temperature isolation cover member 20 includes an isolation cover protective pipe 21 , a temperature insulation plate 22 and an isolation cover flange 23 . The isolation cover protection tube 21 is located in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com